- Created2021.06.15

KIMM, leading the development of hearty robotics technology towards a future where humans and robots can coexist

- Realization of social value through robotics technology -

- Robotics technology for non-face-to-face services -

- Paving the way for the future of robotics in society with the establishment

of the Innovative Robot Center -

The Korea Institute of Machinery and Materials (hereafter referred to as KIMM; President Sang Jin Park), under the jurisdiction of the Ministry of Science and ICT, is a leading institution in the development of robot technology for a future where humans and robots coexist.

On Tuesday, June 15th, KIMM held a conference to announce the establishment of its Innovative Robot Center for the development of next-generation robotics technology. KIMM also presented its latest research achievements, such as a robotic prosthetic leg and hand, a suit-type wearable robot, a human-like hand and all-round gripper, and a self-driving, unmanned tractor.

KIMM’s work focuses on developing technologies that can realize social value, such as robotics technology for those living with disabilities, for responding to infectious diseases, and for the elderly and workers in fields that require high levels of strength.

In 2017, KIMM was successful in developing the first ever ankle-type smart robotic prosthesis. KIMM proceeded to expand upon this technology, resulting in the successful development of a knee-type robot prosthesis prototype for above-knee amputees in 2021. In addition, KIMM continues its work with the goal of realizing social value through the development of technologies for underprivileged or otherwise marginalized groups in society. Some of these technological advances include a robotic prosthetic hand that recognizes the user’s intended actions and a robotic wheelchair that can freely climb ramps and stairs.

Developed based on the ankle-type robotic prosthesis technology, the knee-type robot prosthetic leg recognizes various walking environments and actively optimizes its movement and power for the given situation, rather than simply supporting the user’s weight. Through such adaptive technology, users can experience more natural ambulation and excessive stress on other joints is reduced. In affiliation with the Ministry of Patriots and Veterans Affairs, the KIMM research team is working with the VHS Medical Center and Chungnam National University Hospital in conducting tests to improve the use of knee-type smart robotic prosthesis technology in real-life environments.

This knee-type prosthesis is particularly meaningful in that it is a follow-up research project that is being conducted at the request of the general public following the successful development of the ankle-type robot prosthesis in 2017. In 2020, in collaboration with the Ministry of Patriots and Veterans Affairs, the KIMM research team provided six ankle-type smart robot prostheses for people of national merit and plans to supply 10 more by the end of this year. In addition, KIMM plans to provide the knee-type robot prosthesis that is currently in development first to individuals of national merit who made sacrifices for the country.

In addition, KIMM is undertaking efforts to develop Korea’s first robotic prosthetic hand. Researchers have already completed the development of a prototype of a robotic hand resembling a human hand. This newly developed robotic prosthesis is the lightest of the prosthetic hands developed in Korea. Its biggest advantage is that the prosthetic can modify the shape of its fingers according to the object that is being handled. Also, by analyzing the electrical signals generated by the muscles, the prosthesis can be controlled with the amputee’s desired hand movements. The research team plans to further develop wrist functions through clinical trials in cooperation with Kyungpook National University Medical School, with the goal of commercialize this technology by 2025.

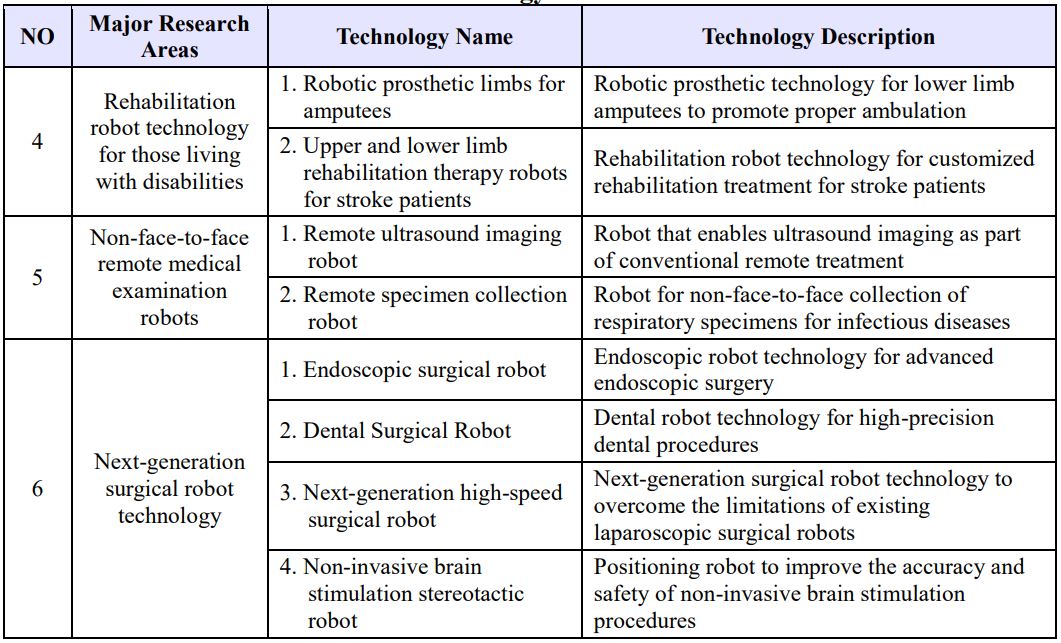

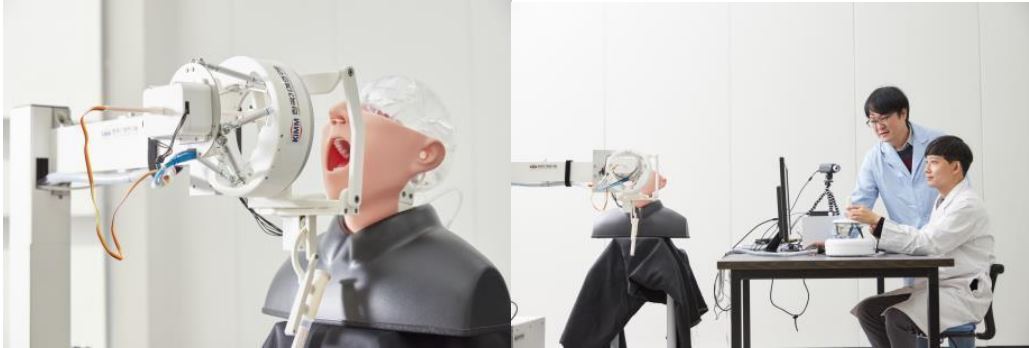

Meanwhile, KIMM has also begun conducting follow-up research and development for the commercialization of non-face-to-face, remote specimen collection robot technology. With the onset of the COVID-19 pandemic in 2020, this specimen collection robot technology, which received a lot of attention for its ability to greatly reduce the risk of infection for medical professionals, has now been transferred to domestic medical device company. In collaboration with these companies, the KIMM research team plans to develop a fully automated system capable of specimen collection and diagnostic testing.

The KIMM research team applied for a follow-up study to improve the safety of specimen collection by automating the process. The goal of this study was to not only improve the ease of use for medical professionals when operating the robotics technology, but also to improve the safety of swab sampling.

Another research project conducted by KIMM was the development of a fabric muscle, a type of wearable robot designed for the elderly and workers in environments that require high levels of strength, both of which are pressing issues in Korea’s aging society. This development is an innovative, wearable robot technology made by weaving a thin, spring-like, shape-memory alloy into a type of fabric or cloth. This fabric can be worn like Spider-Man’s suit, and its strengthassisting technology is useful not only for those who are physically weak, such as the elderly and those living with disabilities, but also for delivery and caregivers who work in environments that require high levels of strength.

The KIMM research team is currently involved in negotiations regarding technology transfer with textile and healthcare companies, both in Korea and abroad. Meanwhile, the team is also working on follow-up studies with the goal of improving upon the performance of fabric muscles, wearable robots, rehabilitation devices, and healthcare products that can be distributed to the public at low prices.

In addition, with the rising popularity of non-face-to-face culture, KIMM has dedicated R&D efforts to introduce robotics technology that can provide various services without the need for human contact.

KIMM’s all-round gripper and human-like robotic hand technology have attracted attention as technologies that can provide customized services in a non-face-to-face society. The all-round gripper can handle objects of various shapes and sizes, from coffee cups to raw chicken. The human-like robotic hand is seen as a sophisticated

The all-round gripper is designed to perfectly match the shape of any given object that it attempts to grip, along with the ability to modify the rigidity of its grasp. As such, whenever it grabs something, the gripper operates as if it were specially designed for that particular object. do. As a result of such technology, not only can this tool be used to grasp any object in daily life, but the role of the robot and the vision system in the holding mechanism is not complex, meaning that it boasts the great advantages of control stability and convenience of operation. This technology can be applied to conduct various tasks such as making samgyetang, making cocktails, picking grapes, etc. with one robot, without the need for a different, specialized robot for each given task. In other words, this is an example of core robot technology that has been successfully designed for non-face-to-face services.

The KIMM research team is conducting follow-up studies to develop grippers that are smaller in size and that can be operated with a strong gripping force even when handling heated or extremely odd and unevenly-shaped objects. In that regard, KIMM is strengthening the practical use of this technology even further, and it is negotiating opportunities for technology transfer with manufacturing companies that handle products of unspecified shapes within their process.

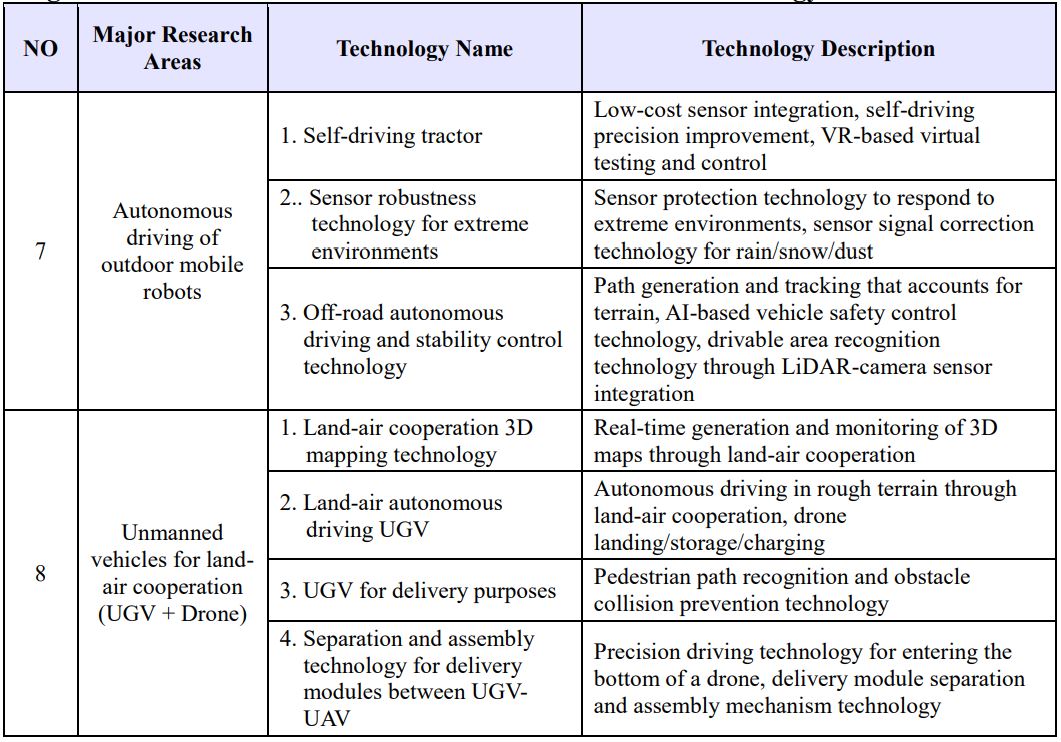

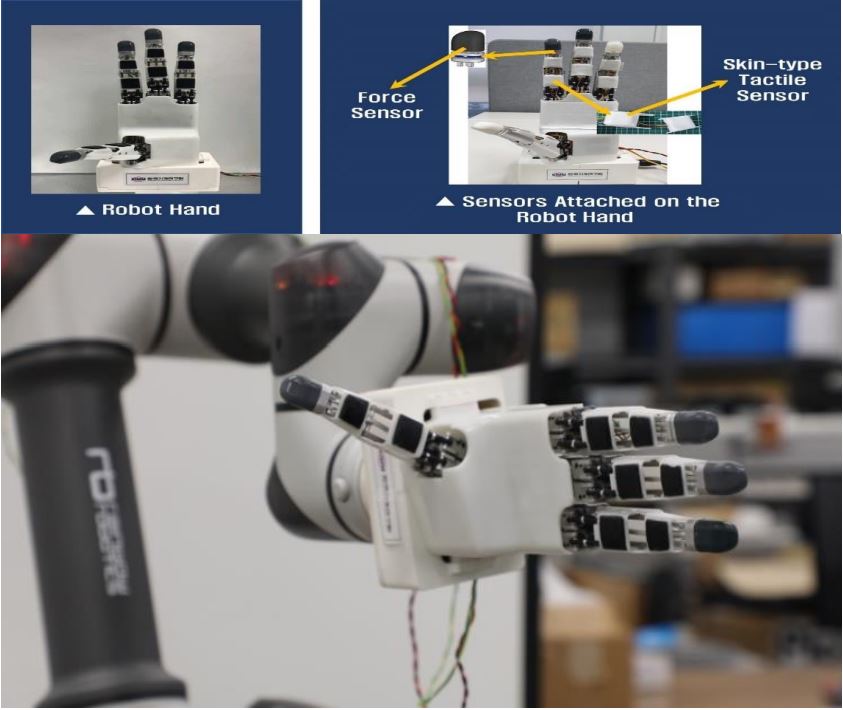

In addition to the ability to grip objects of various shapes, the ability to handle various objects and tools in daily life is also a crucial factor in carrying out non-face-to-face services. To do this, the KIMM research team developed a human-like robot hand, which is composed of four fingers and 16 joints. The research team developed a unique mechanism to support movement in small spaces with a high degree of freedom, similar to the motion of a human hand. A total of 15 motors, embedded inside the palm, were used to move the joints of the fingers through a parallel link structure. The developed robot hand can manipulate various objects and tools in daily life, such as handling eggs or using a pair of scissors. Especially, the research team achieved small size, precise motion and strong gripping force. Also, the robot hand can be easily mounted on various robot arms by modularizing the driving unit. Thus, it is expected to play a big role in robotics technology for non-face-to-face services.

The KIMM research team is also conducting follow-up researches to minimize friction and to improve efficiency by optimizing the joint structure and the kinematic structure of the driving units. Through such studies, KIMM has been able to improve overall performance by increasing the fingertip force up to 34N and reducing the size of the existing control units, thus maximize the advantages of both miniaturization and modularization. KIMM is also in negotiations with a domestic robotics company for potential opportunities in technology transfer, to develop industrial gripper by applying the finger-joint mechanism.

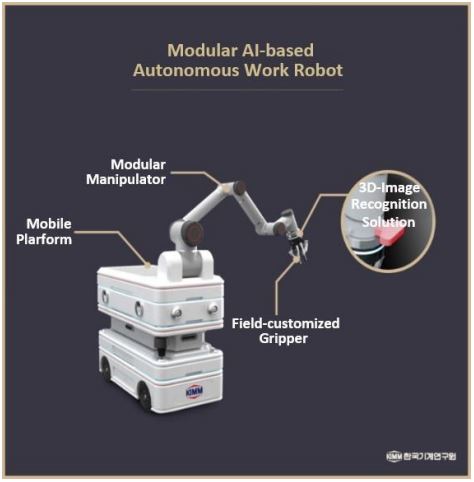

In many working environments that require non-face-to-face services, there is a diverse array of tasks that can be performed by mobile robots, thus prompting the need for such robotics technologies that come in various shapes and can perform various functions. In response to this demand for various mobile robots, KIMM has developed a modular mobile robotics technology that allows users to build mobile robots with their desired functions. This can be done by freely stacking drive modules, sensor and control modules, and manipulator modules like Lego blocks according to their intended use.

Since mobile robots can be built accordingly to be optimized for various purposes, such as transport, monitoring, and operation, they can be effectively used in small and medium-sized manufacturing sites across various industries. To test this, the KIMM research team applied this technology to the automated process of semiconductors and automobile production lines. The team also recently applied this technology to robots that can deliver food in unmanned cafes or perform quarantine tasks without the need for face-to-face contact.

In addition to indoor mobile robotics technology, self-driving tractor technology for the agriculture industry has been developed to address the problems of a decreasing and aging workforce and productivity problems in the industry. Through the development of a path-estimation algorithm that reflects the tractor’s unique characteristics, the average error of straight-line driving was achieved within 10cm on areas of soil where it is difficult to predict road surface conditions. Furthermore, one of the biggest advantages to this technology is that, by using a newly developed sensor fusion precision positioning algorithm, which can achieve similar performance results to existing sensors while using only the GPS and vision sensors, it can provide inertial navigation solutions essential for self-driving tractors at about one-fifth of the price of existing technologies.

The KIMM research team also developed a VR-based unmanned working machine virtual test and control technology, which can be used to test the performance of the self-driving tractor in various agricultural work environments. For such achievements, the KIMM team was awarded the Minister of Science and ICT Grand Prize at the 2021 Digital Transformation Contest, hosted by the Korean CDE Society. In the future, LS Mtron, a technology transfer recipient, plans to use this technology for the development of mid-to-large self- driving tractors and smart farm service technology.

By integrating secured resource technologies, KIMM is preparing a research platform to secure national-level source technologies and is expanding the foundations of practical use of such technologies, which are essential for realizing a robotics society in the future.

To this end, KIMM established the Innovative Robot Center (Director Chanhun Park) in April. This center is a place where outstanding researchers and research projects come together in a single think tank and where technologies can be developed across various fields, including robotic parts, collaborative robots, robot intelligence, logistics robots, robots for those living with disabilities, medical robots, and field robots.

The Innovative Robot Center is expected to play an important role in establishing research and development strategies and preparing technology roadmaps. Such efforts will be conducted through the concentration of R&D capacities and the development of systematic technologies, with the goal of securing future robot technologies deemed necessary at the national level, such as robotics technologies for disadvantaged or marginalized social groups, for non-face-to-face and aging societies, and for reshoring.

Chanhun Park, Director of the Innovative Robot Center, stated that, in order to realize a future in which humans and robots coexist, KIMM aims to develop a research system that can effectively converge individual core technologies from the early stages of R&D planning to achieve results. He added that KIMM will play a leading role in paving the way for the future robotics society by broadening opportunities for collaboration and laying the groundwork for practical use.

Furthermore, in order to take the necessary steps toward expanding the practical use of robotics technology, KIMM has worked hard to promote technology transfer through collaborative research opportunities with various domestic and foreign research institutes and by establishing research-driven companies. One such company, Hugo Dynamics, is promoting the commercialization of an ankle-type robotic prosthetic leg, while a domestic company, Biot Korea, was a recipient of technology transfer for the remote specimen collection robotics technology, which it has begun to commercialize. There are also ongoing discussions with many domestic companies for joint research and technology transfer opportunities with the wearable fabric muscles and humanlike robot hand technologies.

KIMM President Sang Jin Park said that the direction KIMM is taking in robotics technology development is unique in that its goal is to create a future where humans and robots coexist. He added that KIMM will take steps to strengthen this research direction even further and play a leading role as a government-funded research institute in the development of robot technology that can realize social value and respond to essential issues in future society, including aging and non-face-to-face services.

[List of Attachments] - Attachment 1: Glossary of Key Terms

- Attachment 1: Overview of KIMM’s Major Robotics Research

- Attachment 2: Images of KIMM’s Major Robotics Research (photos)

The Korea Institute of Machinery and Materials (KIMM) is a non-profit government-funded research institute under the Ministry of Science and ICT. Since its foundation in 1976, KIMM is contributing to economic growth of the nation by performing R&D on key technologies in machinery and materials, conducting reliability test evaluation, and commercializing the developed products and technologies.

This research project was conducted with support from the Ministry of Trade, Industry and Energy and the project for the establishment of virtual engineering platforms for manufacturing future transportation equipment parts, which is part of the program for technology-based innovation for materials and parts.

Credit : The Korea Institute of Machinery and Materials (KIMM)

Usage Restrictions of Multimedia (Attachment File) : The sources of photos and research results from KIMM must be specified.

- Attachment 1: Overview of KIMM’s Major Robotics Research

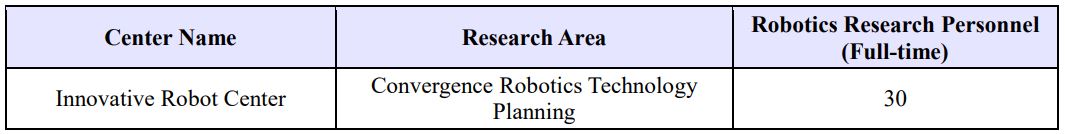

1. Research Personnel

◌ Innovative Robot Center

* Researchers from the Department of Robot Mechatronics, Department of AI Machine Research, Department of Medical Support Robotics, and Department of Smart Industrial Machine Research work concurrently.

◌ Research Departments

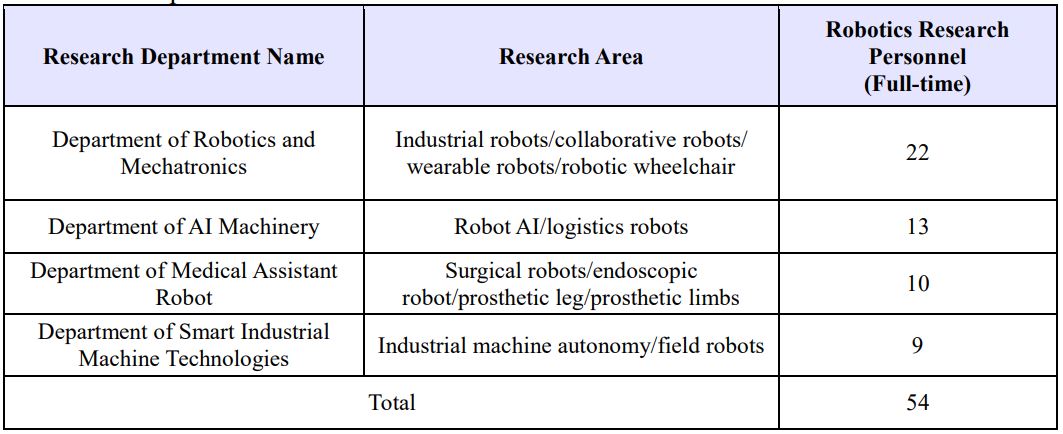

2. Robotics Research Budget (As of 2021)

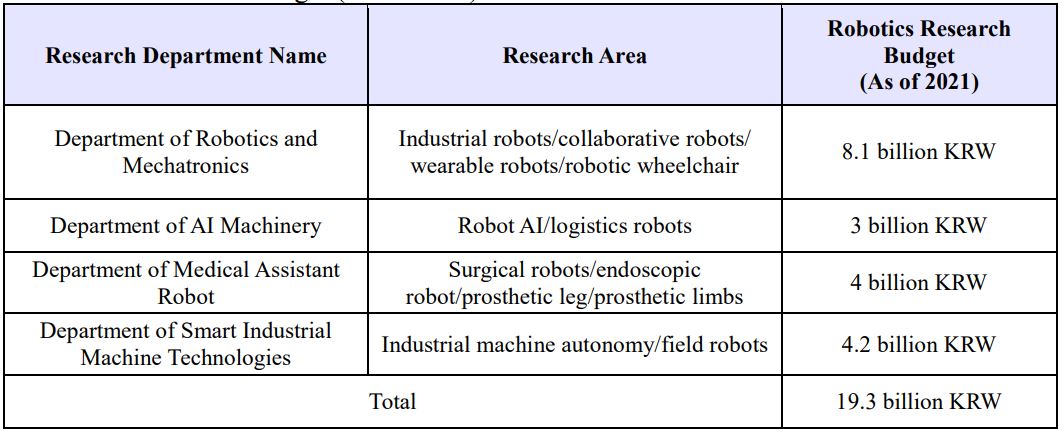

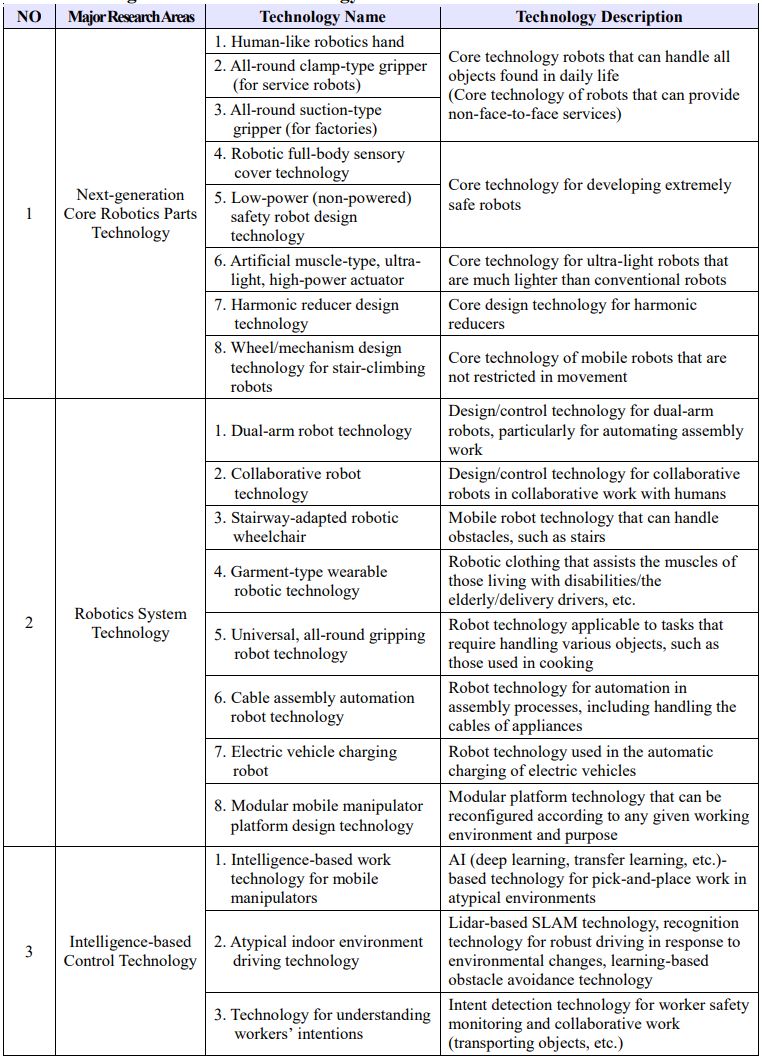

3. Robotics R&D Progress Overview

◌ Industrial/logistics Robotics Technology

◌ Medical/rehabilitation Robotics Technolog

◌ Agricultural/national defense/outdoor mobile Robotics Technology

- Attachment 2: Images of KIMM’s Major Robotics Research (photos)

Knee-type Robotic Prosthetic Leg

Photo description: A robotic prosthetic leg with knee attachment developed by KIMM for above-knee amputees. Developed based on existing ankle-type robotic prosthesis technology, this prosthetic leg does not only support the weight of the user, but can actively optimize its movement and power for any given situation by recognizing various walking environments.

(Dr. Hyun-soo Woo, Head of Department of Medical Assistant Robot)

Robotic Prosthetic Hand

Photo description: A prototype of a robotic prosthetic hand developed by KIMM to resemble a human hand. This technology is the lightest among the prosthetic hands developed in Korea, and the fingers are capable of changing their shape to accommodate different objects. (Dr. Joon-wook Choo, Principal Researcher)

Wearable Fabric Muscle

Photo description: Wearable fabric muscle developed by KIMM. This fabric is light and soft, and can lift 1,500 times its own weight due to thin, spring-like shape memory alloys that are woven together through a similar method used when weaving cloth.

(Dr. Cheol Hoon Park, Principal Researcher)

Remote Specimen Collection Robot

Photo description: A remote, non-face-to-face specimen collection robot developed by KIMM. Using this technology, medical professionals can collect specimens needed for infectious disease testing while avoiding close contact. As such, specimens can be collected safely without the risk of infection.

(Dr. Jun-ho Seo, Principal Researcher)

All-round Gripper

Photo description: An all-round gripper developed by KIMM. This technology can be used for non-face-to-face services in various fields, as it can freely hold objects of any shape, from raw chicken to tofu and even wine glasses.

(Dr. Chanhun Park, Director of Innovative Robot Center)

Human-like Robotic Hand

Photo description: A human-like robot hand developed by KIMM, with a structure developed based on that of the human hand; this technology can handle a variety of objects, from grabbing and moving eggs to using scissors or spraying.

(Dr. Hyun-min Do, Principal Researcher)

Modular Mobile Robot

Photo description: A modular mobile autonomous work robot developed by KIMM. This modular robot technology can assemble and configure various modules, such as movement, control, and operation as desired in small and medium-sized manufacturing companies and on-site for non-face-to-face services.

(Dr. Chang-Hyun Kim, Head of Department of AI Machinery)

Self-Driving Tractor

Photo description: An unmanned tractor working in a real-life environment using VR-based unmanned machine virtual testing and control technology developed by KIMM.

(Dr. Mu-hyun Cha, Principal Researcher)