- Created2021.06.30

KIMM Develops Stirling Cooler, Key Technology for Ultra-low Temperature Cold Chains

- Improved energy efficiency and temperature stability, while saving the environment -

- The new ways for semiconductor and bio industries with ultra-low temperature cooling technology -

The Korea Institute of Machinery and Materials (President Sang Jin Park, hereafter referred to as KIMM), an institution under the jurisdiction of the Ministry of Science and ICT, has developed a Stirling cooler, which is the key technology of ultra-low temperature* cold chains. The ultra-low temperature cooler operates with Stirling thermodynamic cycle, and it shows twice more energy efficiency than traditional vaporcompression cooling technology. This technology also enables more precise temperature control and reduces the size of the cooling device by more than half. Furthermore, another advantage to this technology is that it is an environment-friendly technology as it uses helium (He) as a refrigerant.

* Generally speaking, cryogenic temperatures refer to temperatures of -150℃ or less, while ultra-low temperatures refer to temperatures ranging from -60 to -150℃.The research team led by Dr. Seong-je Park, director of the Energy Systems Research Division at KIMM, was successful in developing a Stirling cooler for ultra-low temperature freezers. Within the cooler, two pistons oscillate to compress and expand the helium gas periodically. The cooling effect is generated by gas expansion, and thus the Stirling cooler can pump heat from ultra-low temperature to room temperature.

Compared to traditional cooling systems that are based on vapor-compression technology, Stirling coolers can be downsized into a single unit, as opposed to being composed of several parts, including compressors, heat exchangers, expansion device, and oil separators, that are connected by piping. Also, Stirling coolers are capable of continuous temperature controls and are offering a broader range of temperature control.

Another important thing to note is that Stirling coolers use helium (He) as a refrigerant rather than using other refrigerant gases that cause negative impacts on global warming. Helium, an absolute environment-friendly refrigerant with 0 GWP, exceeds the low GWP refrigerant that is being actively applied in the current field of cooling systems.

With this technology, experts are able to build ultra-low temperature cold chains more efficiently. Cold chains have recently been a topic of great interest due to their role in transporting COVID-19 vaccines. Also, due to advances made in the semiconductor industry, Stirling coolers are gradually gaining attention as a ultra-low temperature cooling technology that will be in high demand in the future.

The researchers at the KIMM Energy Systems Research Division have been researching Stirling cooling technology for the past 20 years and, during that time, have accumulated unparalleled research capacities in Korea. They have developed small Stirling cryocoolers specifically designed for infrared sensors. The research team has also developed Stirling engines that are used in cogeneration units for household use and large Stirling cryocoolers that are used in liquid nitrogen cooling.

The reason why these research results are so meaningful is because they demonstrate the possibilities of expanding the use of Stirling cooling technology across both cryogenic and ultra-low temperature applications to explore the creation of new industries, such as the bio and semiconductor industries.

Dr. Seong-je Park, the director of the KIMM Energy Systems Research Division, stated that ultra-low temperature Stirling coolers will set the stage for broadening potential applications of Stirling cooling technology and creating new industries. He also added that researchers at KIMM will continue to do their best in conducting additional research and development on such technologies, including on methods to increase the cooling capacity of ultra-low temperature chillers for use in the bio industry and for processes in semiconductor production.

[List of Attachments] - Attachment 1: Research Outline and Terminology

- Attachment 2: Stirling Cooler for Ultra-low Temperature Freezers (Photo)

The Korea Institute of Machinery and Materials (KIMM) is a non-profit governmentfunded research institute under the Ministry of Science and ICT. Since its foundation in 1976, KIMM is contributing to economic growth of the nation by performing R&D on key technologies in machinery and materials, conducting reliability test evaluation, and commercializing the developed products and technologies.

This research project was carried out with the support from the Ministry of Trade, Industry and Energy’s Industrial Technology Innovation Project and Energy Technology Development Project.

Credit : The Korea Institute of Machinery and Materials (KIMM)

Usage Restrictions of Multimedia (Attachment File) : The sources of photos and research results from KIMM must be specified.

- Attachment 1: Research Outline and Terminology

1. Research Outline 1) Project Title: Development of ultra-low temperature freezers using Stirling cooling technology

2) Principal Investigator: Dr. Seong-je Park, Principal Researcher & Director of the Energy Systems Research Division 3) Project Information - Type: Ministry of Trade, Industry and Energy’s Industrial Technology Innovation Project and Energy Technology Development Project - Research period and funding: May 2018 to April 2021; total budget of 3.54 billion KRW; 1.29 billion KRW for KIMM - Participating organizations · Leading: ilShinBioBase Co., Ltd. (development of ultra-low temperature freezer) · Participating: KIMM (development of Stirling cooler)

2. Terminology 1) Vapor-compression Cooling - A cooling method used in general household refrigerators or freezers in which the cooling cycle is composed of compression, condensation, expansion, and evaporation of the refrigerant. The evaporation temperature of the refrigerant is determined by the cooling temperature, which means that the cooling temperature of the device is limited by the type of refrigerant used.

- Most household refrigerators or freezers work with one refrigerant, but to reach ultralow temperatures, it is necessary to use a mixture of refrigerants.

- Since lubricating oil is used to lubricate the inside of the compressor, there is a risk of clogging the flow path due to oil solidification at ultra-low temperatures.

2) GWP (Global Warming Potential) - An index indicating the impact of gases on global warming. The warming effect of carbon dioxide is expressed relative to 1. As such, the higher the GWP, the greater the adverse impact on global warming.

- Refrigerants used in vapor-compression cooling generally have a GWP of 1,000 or greater. In recent years, aligning with the generational pursuit of achieving low GWP, these refrigerants have been replaced with natural refrigerants that have a GWP of 10 or less, such as ethane and ammonia.

- Helium has a GWP of 0, which means that it does not adversely impact the climate. Also, as an inert gas, it poses no risk of explosion.

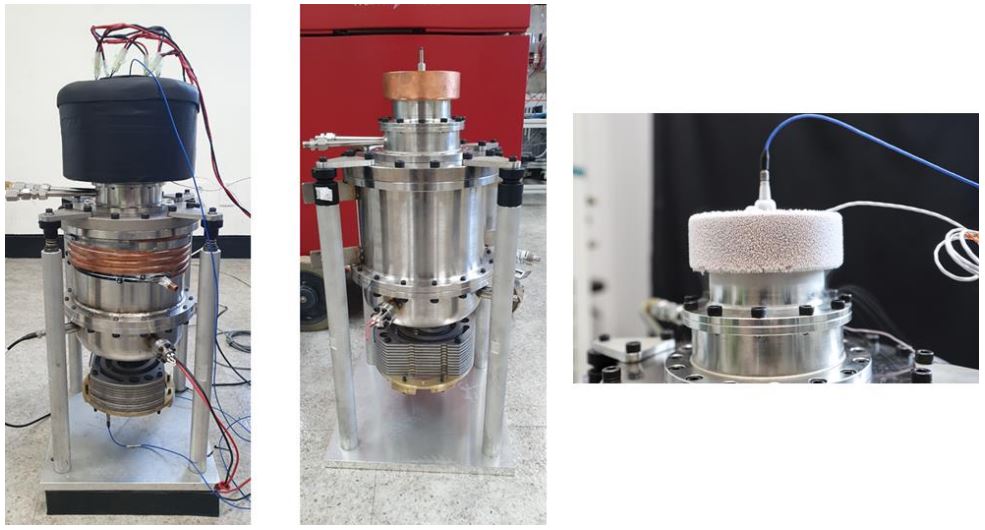

- Attachment 2: Stirling Cooler for Ultra-low Temperature Freezers (Photo)

Photo description:

(Left) Stirling cooler for ultra-low temperature freezers developed by Dr. Seong-je Park, director of the KIMM Energy Systems Research Division

(Center) As opposed to traditional vapor-compression cooling methods, which use complex parts that are connected by piping, the ultra-low temperature Stirling cooler is composed of a single sealed structure. The upper part of the device is cooled to ultra-low temperature by the movements of internal pistons that cause repeated compression and expansion processes.

(Right) Crystals formed on the upper part of the cooler, which has been cooled to ultra-low temperature

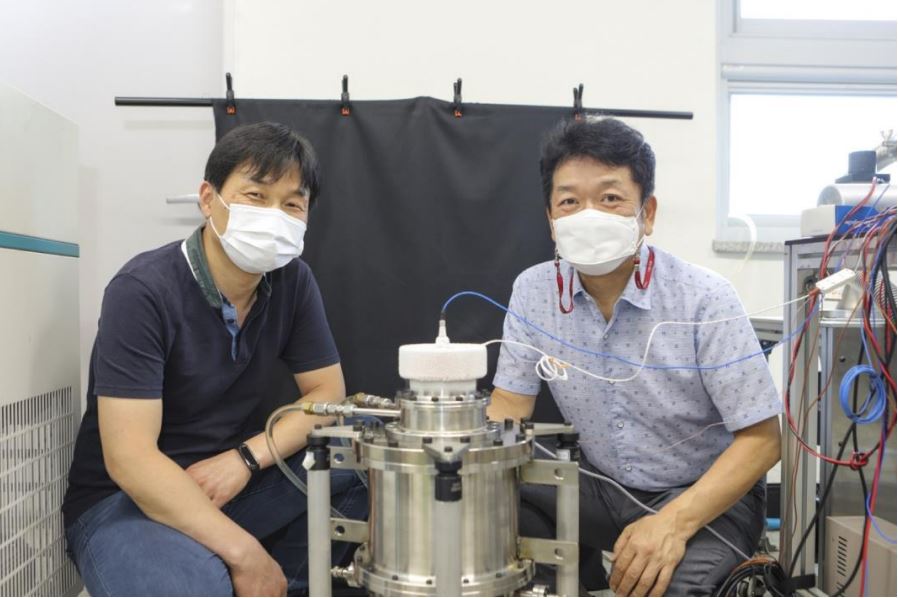

Photo description: Dr. Seong-je Park (right), director of the KIMM Energy Systems Research Division, and Dr. Junseok Ko (left), principal researcher at KIMM