Ultrashort pulse laser-based AMOLED TV non-thermal repair

technology and repair device

Client / Market

- Companies interested in non-thermal repair machining technology of large size

AMOLED panel

Necessity of this Technology

- Non-thermal repair process is necessary, and a system for large size processing

needs to be established.

- Repair process using nanosecond laser inevitably causes thermal damage to the object.

- In case of processing an organic matter that is very sensitive to the processing

temperature, unnecessary damages are caused from heat around the processing unit.

- When defect or error occurs during large size AMOLED panel manufacturing, the

entire quantity is discarded. From the production yield perspective, this is a serious

downside, therefore a repair technology is needed.

Technical Differentiation

- Ultrashort pulse laser has relatively short pulse width compared to nanosecond

laser and can be used for non-thermal processing to minimize damage from heat

on the object.

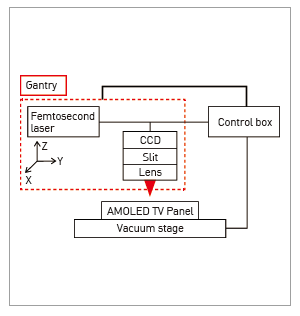

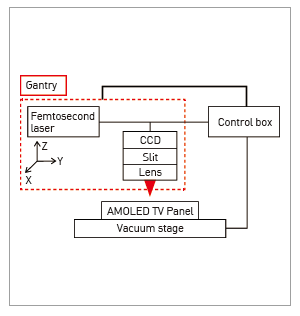

- With the ultrashort laser machining system using a gantry, a large size AMOLED

panel can be repaired.

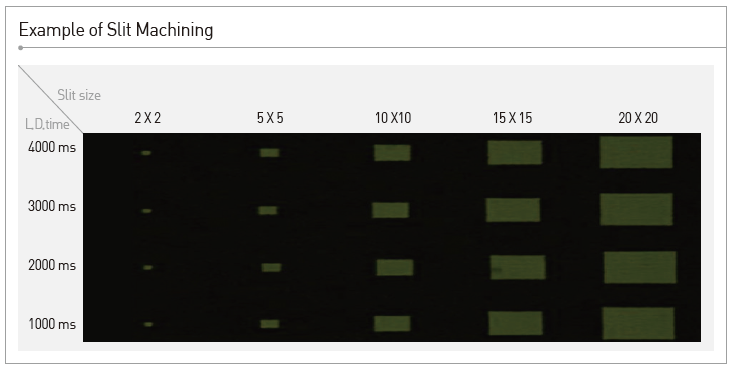

- The beam size can be adjusted with the motorized slit to adjust the beam shape in

the light path of the ultrashort pulse laser-based machining system, and with the

square-shaped beam, machining of area requiring repair can be executed with the

minimum line width of 500 nm.

- Using the gantry established for this system, the defective area of the large size

AMOLED panel is detected and is quickly repaired using the ultrashort pulse laser.

Excellence of Technology

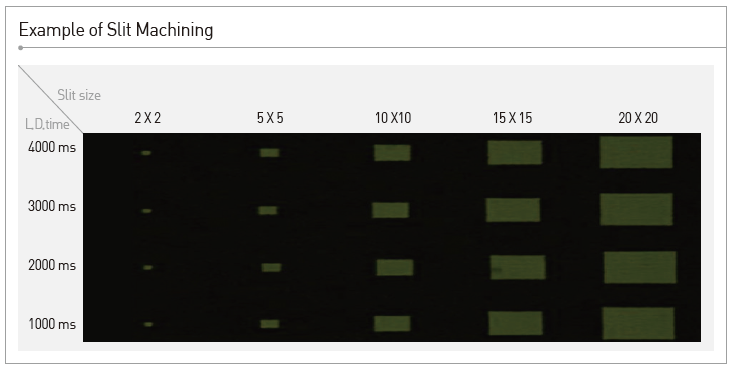

- The process irradiates the femtosecond laser beam to the target layer and

processes the desired area. It is utilized for partial repair of a specific defective area.

- For this, the beam shape and the machining size is adjusted through the slit.

- It is the blueprint that roughly shows the active organic self-illuminator TV’s

femtosecond laser repair system. For large area repair, the gantry system is used

to adjust the laser beam location, not the target for repair, for machining.

- The repair target is fixed with the vacuum chuck of the stage to minimize the

elevation difference error.

- The head researcher for this technology has over 10 years of research experience in

ultrashort femtosecond laser-applied superprecision micro machining field.

Current Intellectual Property Right Status

PATENT

- Non-thermal Repair Method and Device for Full HD High Resolution Mobile Active

Organic Self-illuminator (KR1477005)

- Non-thermal Repair Method and Device for Active Organic Self-illuminator Using

Selective Pulse Width Tunable Laser (KR1450767)

- Thermal and Non-thermal Converged Repair Device for Active Organic Selfilluminator

(KR1387996)

- Non-thermal Repair Method and Device for Transparent Active Organic Selfilluminator

Using Ultrashort Pulse Laser (KR2012-0042367)

- Non-thermal Repair Method and Device for Large Size Active Organic Selfilluminator

Using Ultrashort Pulse Laser (KR2012-0056576)

- Non-thermal Repair Method and Device for Active Organic Self-illuminator Using

Ultrashort Pulse Laser (KR2012-0016303)

- Non-thermal Repair Method and Device for Flexible Active Organic Self-illuminator

Using Ultrashort Pulse Laser (KR2012-0016139)

|