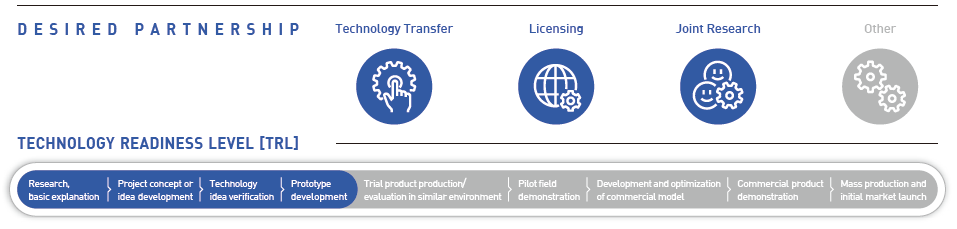

Laser glass direct bonding: Laser sealing technology where two

glass plates are directly welded without adhesive to seal

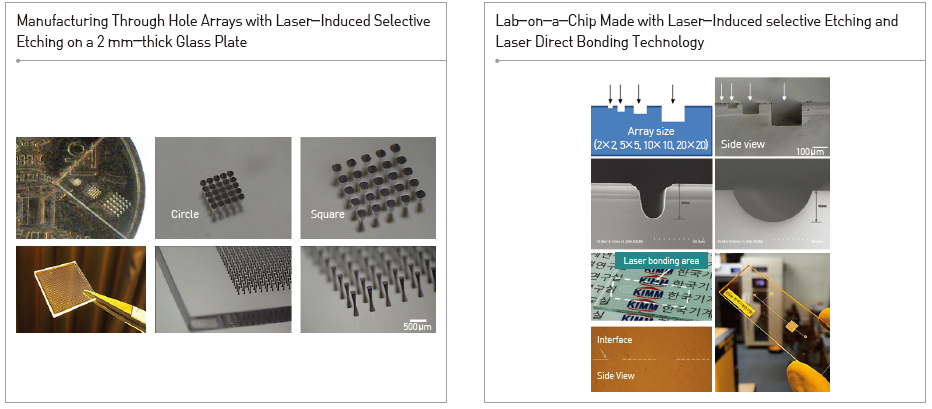

Laser-induced selective etching: creating micro 2.5D/3D

structures by maskless laser direct patterning of desired patterns

on the transparent brittle plate such as glass plates (fused silica,

borosilicate) or sapphire followed by laser-induced selective etching

with the area where laser is irradiated

Client / Market

- Device manufacturer requiring alternatives to MEMS process

- Medical device and component manufacturer

- Display, aerospace, sensor device manufacturer

Necessity of this Technology

- Existing glass bonding technology :

- The existing technology using glass frit between two glass plates to bond and melting the frit

with laser leads to significantly lower bond strength compared to direct bonding of the plates

as moisture and air can penetrate the gap between the plates where the frit has been applied.

- It is difficult to apply the conventional method of heating the entire area for bonding if the

plate has patterns that are vulnerable to heat.

- Laser-induced selective etching :

- It is difficult to drill a micro through hole of high aspect ratio on brittle materials like glass

and quartz plates using mechanical machining.

- Also, it is impossible to form a 3D embedded channel inside the plate.

- Micro machining with laser ablation requires expensive high-powered system, and to

adjust the taper angle, expensive trepanning optical system is required

Technical Differentiation

- Laser glass direct bonding :

- This technology uses tightly focused ultrashort pulsed laser beam to instantaneously

melt local zone of the glass plate to directly bond the interface of two glass substrates,

and it does not require adhesive, frit, or absorption layer, which means clean bonding

and the bonded area remains transparent.

- The bond strength is superior than bonding with heterozygous materials.

- The size of welding seam from bonding is only dozens of micrometer and following the premachined

pattern on the plate surface, bonding can be done locally with the direct writing

method. Heat-sensitive device and circuit are protected while welding around the pattern.

- Laser-induced etching :

- This technology uses less energy than ablation that it can be run with low-power laser

system. The depth of machining on the transparent plate is determined by the focus

point that various shape of 3D structures can be manufactured.

Excellence of Technology

- Laser glass direct bonding :

- Enables hermetic sealing of MEMS components and organic component vulnerable to

air and moisture

- Possible to manufacture implantable subminiature sensor and medical components as the

device can be manufactured using bio compatible glass-without using harmful adhesive

- Laser-induced selective etching :

- Possible to process a through hole, blind hole with high aspect ratio through selective

etching (aspect ratio over 1:10)

Current Intellectual Property Right Status

PATENT

- Bonding Method of Multiple Member Using Ultra Short Pulse Laser (KR1453855)

- Bonding Device Using Laser and Bonding Method of Multiple Member Using the

Device (KR1528344)

KNOW-HOW

- Ultrashort pulsed laser-induced glass selective etching technology (ultrashort

pulsed laser direct writing technology and maskless etching process know-how)

- Ultrashort pulsed laser glass direct bonding know-how

- Bond strength and quality assessment know-how

|