System to collect and process production facility (machine tool) status

information real-time System to collect the status information with

system interface regardless of the facility type

Client / Market

- Machine tool manufacturer

- Companies needing production information management system establishment

(MES, Manufacturing Execution System) and process management system and SI

companies

Necessity of this Technology

- Generally applying and extracting the status information is difficult as the

specifications differ depending on the NC mounted on the machine tool.

- Regardless of the specifications of the NC mounted on the machine tool, desired

status information is extracted and provided to the manager to process tertiary

information.

Technical Differentiation

- Existing development extracts the status information from NC that the method of

using and S/W are different depending on the NC type.

- Such methods require high cost or are inconvenient as the license for related S/W

needs to be purchased separately.

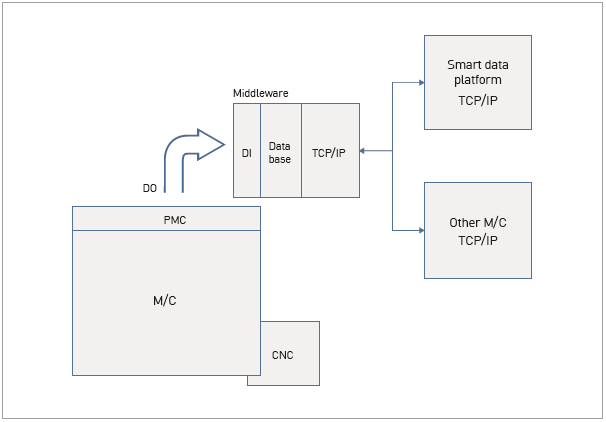

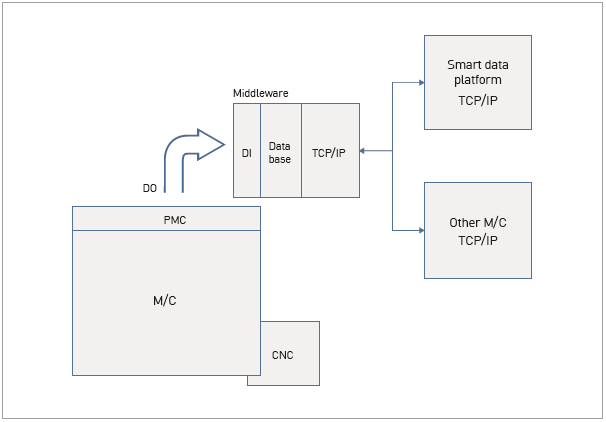

- This development can collect status information from the machine tool’s PLC (PMC)

interface regardless of the NC type that limitations caused by NC type are surpassed

and related cost is significantly decreased.

Excellence of Technology

- The purpose of this technology is to use PLC (PMC) mounted to the machine tool to

extract the status information of the machine tool; it can be mounted to the machine

tool regardless of the NC specifications.

- This enables communication with other machine tools, and accumulated status

information can be used as the foundation for establishing big data on status

information of the machine tool.

- This enables establishment of 4th industry data platform and utilization of the

information as backdata of related ICT program to lead to smartification of the

machine tool.

- Provides convenience to the user by displaying the status information real-time

Current Intellectual Property Right Status

KNOW-HOW

- Heterogeneous machine tool interface standard design

|