Technology for development of hybrid heating and cooling roll with

600 mm in width easily handling various hot embossing processing

conditions and ultrafine pattern formation

Client / Market

- Next generation semiconductor requiring fine pattern, display device, bio device,

optical communication component and high energy component

Necessity of this Technology

- To realize high performance and high density, ultrafine shape processing of several

hundred nm to several dozens μm is crucial. However, existing LIGA process or fine

mechanical machining are encountering financial, technical limitations that there is

a demand for new technology and device that will enable ultrafine shape production

(below several dozens μm).

- Compared to low and middle temperature embossing that can treat 300 mm

wafer, high temperature embossing has technical difficulties with adding uniform

temperature and pressure throughout the entire working area. Press type high

temperature embossing can easily add uniform temperature and pressure

throughout a small area but has limits in continuously handing a large area.

- UV curing type of roll embossing process requires a vacuum facility and specific

resin that reacts to UV. The cost for process design, process maintenance/

production is high.

Technical Differentiation

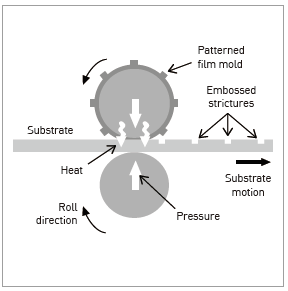

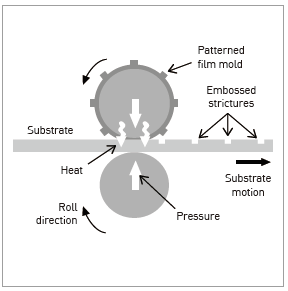

- The technology heats the polymer beyond the glass transition temperature, uses

a stamp to stamp fine structure while polymer is soft, and then cools and cures.

Ultrafine patterning with a size below micron can be performed.

- It is easy to manufacturer optical components like beam splitter, lens, and

hologram and non-reflective substrate, and optical filter. When used for solar cell

manufacturing, it can be used for polymer embossing process in the insulator layer

or the active layer.

- It can also be widely used for general industry other than hot embossing such as

textile and paper manufacturing.

- With heating and cooling function inside the roll, the surface temperature can be

adjusted quickly-enables active process design.

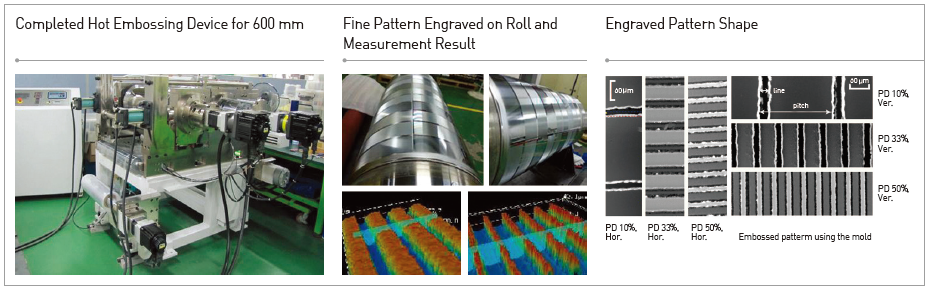

- Surface temperature consistency secured for hybrid roll of 600 mm in width for

micropattern making on large area (Temperature deviation: ±2℃, Maximum

temperature: 250℃) (temperature deviation: ±2℃, Maximum temperature: 250℃)

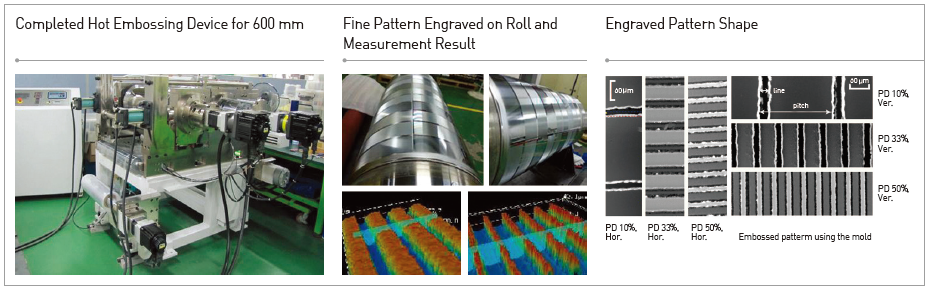

- The result of experiment with hot embossing device and hybrid roll of 600 mm in

width showed pattern density change-based imprint rate of 70% where the material

was PMMA and line width was 20 μm.

Excellence of Technology

- Hybrid roll was used as a pattern roll and heating roll, and a cooling device was

added to improve cooling effect after patterning. By adding a mechanical part to

grasp the performance following the contact area of film and roll (for analyzing

effect of pre-heating and cooling), a concept of adjusting the contact amount of the

film and roll for pre-heating and cooling effect was adopted.

- A sensor part was added to monitor the roll transformation and contact status

during pressurization.

Current Intellectual Property Right Status

PATENT

- Thermal Variable Type Hot Embossing Device and Method (KR1064492)

- Impact Print Type Hot Embossing Device (KR0999538, JP5604633)

- Temperature Control Method of Roll with Heating and Cooling Function (KR2013-

0058658)

- Press Roller for Consistent Pressurization of Roll-to-Roll Device (KR2013-

0105199)

- Patterning System Using Roll-to-Roll (KR2013-0122058)

- Nip Pressure Monitoring Device and Method for Roll-to-Roll Device (KR1519846)

- Line Type Micro Pattern Sheet Material Forming Device (KR1221830)

KNOW-HOW

- Technology for designing hybrid roll with heating and cooling function

- Hybrid roll-based hot embossing device design technology

|