Dental barrier membrane with porous membrane using a bioplotting device

Client / Market

- Customized medical artificial scaffold

Necessity of this Technology

- It is a 3D scaffold fabrication for reconstruction of the defected parts in the body.

- Solvent-casting particulate-leaching

- Gas foaming/salt leaching

- Fiber meshes/fiber bonding

- Phase separation

- Melt molding

- Freeze drying

- In the 3D scaffold fabrication for tissue engineering and regenerative medicine, there are different types of manufacturing with appropriate strength, biodegradability, and non-toxicity, but there is no standardized method, and this is an actual obstacle to product commercialization (item approval, etc.)

- It needs to be biocompatible and non-toxic.

- Different mechanical, physical properties and fabrication are required for different purpose of use.

- Volume, porosity and biodegradability for a large surface area is needed.

Technical Differentiation

- Structural characteristics (pore size, porosity), materialistic characteristics (biocompatibility, degradation), and mechanical properties of the scaffold can be adjusted to suit the convenience of the user.

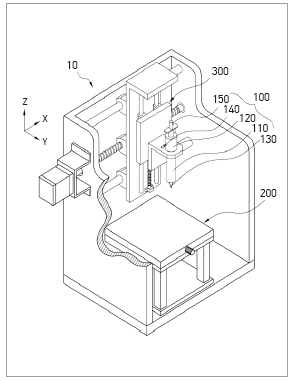

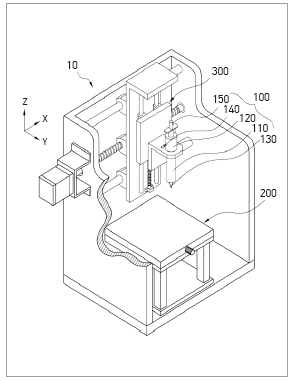

- Using a bio-plotting device, manufacturing is simple, and scaffolds of various size and shape can be manufactured.

- It is easy to control the thickness of certain part (perhaps requiring strength maintenance) or the pore size during manufacturing.

- Bio-plotting system equipment has the benefit of being able to use desired materials to manufacture various types of scaffolds under different conditions and allows for easy reproduction.

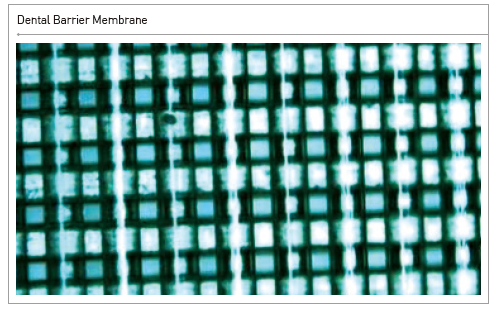

- After covering the bone graft material-filled gum surface, it takes 2 to 3 months until it is absorbed and degraded that the bone graft material maintains necessary shape and protects from the outer environment until the area is recovered. As it is absorbed and degraded at the appropriate time, the effect of the treatment is enhanced and the user satisfaction is also improved.

- Not only PLC, but various combinations can be used artificial scaffolds (PCL/HA, PCL/TCP) for different bio fields.

Excellence of Technology

- Dental barrier membrane is formed with multi-layers of porous membranes by adjusting the transfer stage and jet stage of the bio-plotting apparatus.

Current Intellectual Property Right Status

PATENT

- Dental Barrier Membrane (KR1352366)

- Apparatus for Forming of Sliding Prevention of Artificial Lacrimal Canaliculus and Method for Manufacturing Artificial Lacrimal Canaliculus (KR1368850)

- Plotting Apparatus for Hydrogel (KR1306264)

- The Method for Preparation of Cell Culture Scaffold (KR1270143, US13/160577, SP201104380-9)

- The Method for Preparation of Hybrid Scaffold for Bone-Cartilage Regeneration (KR1284080)

- Apparatus for Manufacturing Regeneration of a Three-Dimensional Tissue (KR1271238)

- Three-Dimensional Manufacturing Apparatus for Cell Culture Product (KR1185506)

- Manufacturing Apparatus and Manufacturing Method for Cell Culture Scaffold (KR1153728)

|