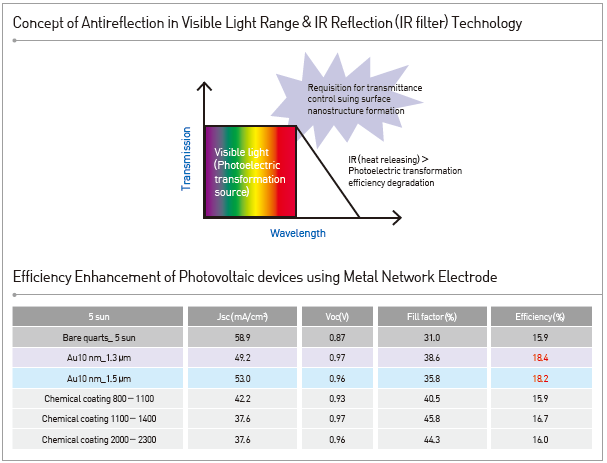

Manufacturing and design of anti-reflecting plane/curved (lens) glass for the visible light range and metal nanostructure-based selective filter for the IR range

- Manufacturing and design of plane glass with reflectance below 1% in 380 nm-780 nm (visible light range)

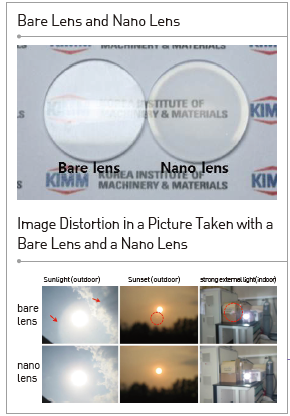

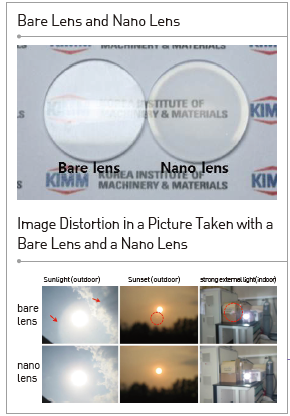

- Antireflecting lens technology for anti-flare/ghost effect

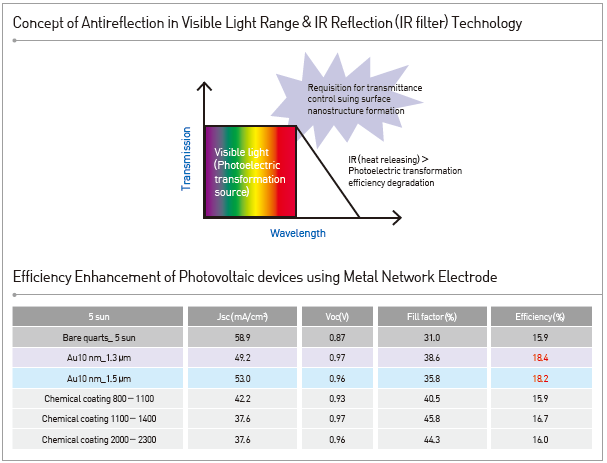

- Metal nanostructure-based selective filter fabrication and design for heat blocking and emission in NIR range

Client / Market

- Antireflecting plane glass: Internal and external materials for construction, glass for display, glass for viewing at zoo, automobile glass, solar ray device, etc.

- Antireflecting curved glass (lens): Optical lens, microscope lens, optical equipment for military use, etc.

- IR filter: Solar ray-related new and renewable energy device, heat shield, hot and cold insulation material

Necessity of this Technology

- It is too hard to make anti-reflecting surface with low cost and simple fabrication method based on existing chemical coating process due to the complexity of refractive index matching.

- The simple particlse coating method can decrease the cost lower than existing method, but the reflectance can be reduced 1 to 2% in the visible light range (for 550 nm).

Technical Differentiation

- With a lower production cost than the chemical coating method, lower than 1% reflectance can be achieved in visible light range.

- Due to the relative difference in scale and curvature of the surface structure, stable antireflecting surface structure can be formed by applying the existing surface structure formation method.

- The surface nanostructure formed lens can prevent the flare and ghost image which are made by the internal reflection of lens fundamentally.

- With periodic surface nanostructure formation on substrate, regardless of the type of substrate, antireflection effect for a broad wavelength can be induced.

- The antireflection can be made by the surface nanostructure that the property can be maintained under various environments such as chemical, humidity, UV rays.

- Metal nanostructure based selective IR filter produced with a similar process to the antireflection surface formation can be applied as the selective IR filter in various IR range.

Excellence of Technology

- Lower than 1% of reflectance in visible light range can be achieved, and not only flat surface but also curved surface can provide antireflection effect with uniform refractive index matching

- Based on the selective IR filter using regulating of surface metal nanostructures such as size, shape, and materials can decrease the heat releasing for enhancement of efficiency of photovoltaic devices.

Current Intellectual Property Right Status

PATENT

- Manufacturing Method for Anti-Reflective Surface and Super Water-Repellent Surface (KR1014277)

- Optical Filter with Function of Frequency-Selective Transmission and Reflection (KR1688186)

KNOW-HOW

- Particle-based surface nanostructure formation method

- RIE-based surface nanostructure formation method

- Metal nanonetwork formation method

- Surface nanostructure based Transmittance simulation for antireflection effect

|