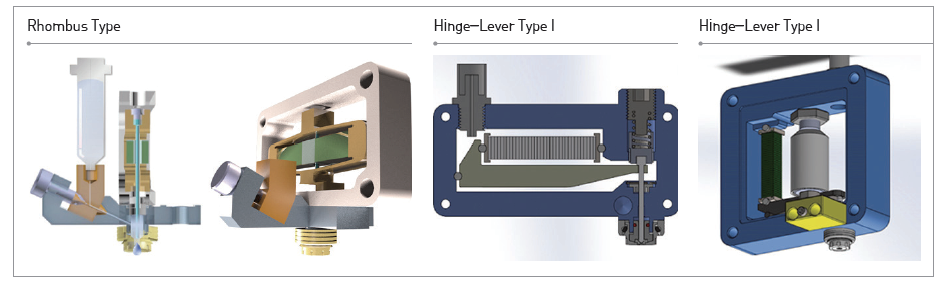

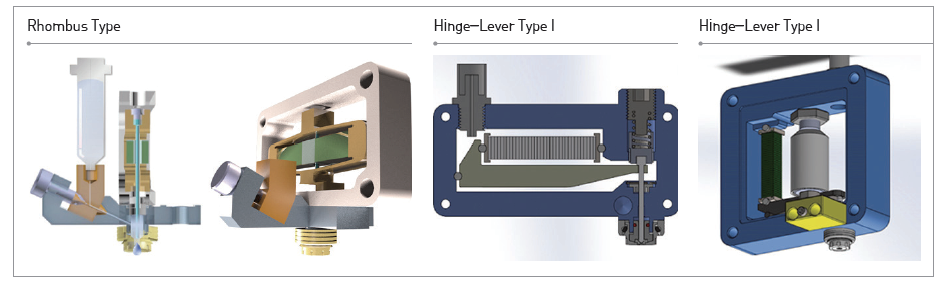

This technology is a piezoelectric-driven jet dispensing head

mechanism design technology that can generate 2D and 3D pattern

at a high speed by dispensing viscous liquid at a fixed amount with

ultra-fine precision.

Client / Market

- Fields requiring precise, fixed-amount dispensing of high viscosity liquid

- High viscosity epoxy precision dispensing: epoxy jet dispensing for semiconductor component bonding process

- Functional paste precision dispensing: Paste jet dispensing for LED chip packaging process

- Lubricant dispensing: Grease and jetting for high value-added components requiring continuous supply of the minimum amount of lubricant

Necessity of this Technology

- Vaccines or drugs to livestock are usually delivered with a needle-syringe so there is a possibility of disease spread due to reuse of needles.

- Injection of accurate amount on the right spot is difficult using a syringe with a needle due to animal movement, and there are issues regarding increasing fatigue of the worker and possibility of safety accident.

- Pork quality may decline due to the needle mark and broken needle during injection and stress caused from injection.

- Imported needle-free injectors are expensive, heavy, or make noise during operation that is why their use is limited at livestock farms.

Technical Differentiation

- High-speed driving is possible using piezoelectric actuator with response dozen times higher compared to solenoid.

- Droplets are formed with the high force of piezoelectric actuator that high viscosity droplets can be dispensed.

- While ascending the tappet by extending displacement of piezoelectric actuator, the liquid is injected through the nozzle and the tappet descends at a high speed for instant high pressurization to dispense fine droplets.

Excellence of Technology

- The problems of limitations with viscosity, speed, and micro droplet formation of existing piezoelectric dispenser are overcome, and independent design of piezoelectric jet dispenser mechanism of the same level as foreign products became possible.

- Can reduce cost occurring from drug loss and purchasing expensive imported products

Current Intellectual Property Right Status

PATENT

- Jet Dispenser Using Hinge Lever Type Displacement Extension (KR2016 0064095)

- Bimorph Piezoelectric Actuating Dispenser with Cutting Jet Type (KR1190080)

- Cutting Jet Type Dispenser Using Pressurized Area Amplified Displacement (KR1190119)

- Cutting Jet Type Dispenser Using Amplified Perpendicular Displacement (KR1190083)

- Cutting Jet Type Dispenser Using Hinge Lever (KR1059746)

KNOW-HOW

- Stacking type piezoelectric actuator mounting jig design technology

- Stacking type piezoelectric actuator initial compressibility setting design

- Nozzle & tappet end contact and sealing mechanism design technology

- Viscosity control technology for high viscosity liquid

- Stacking type piezoelectric actuator driving control technology for droplet formation

|