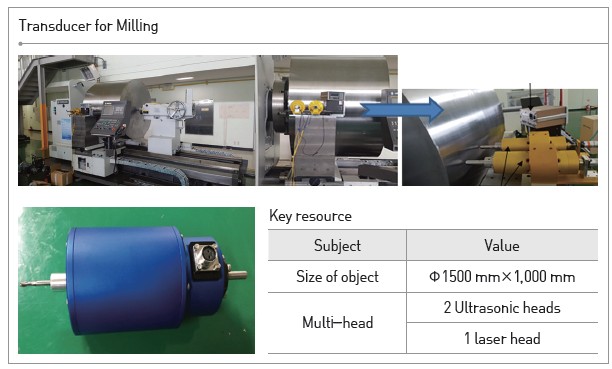

Ultrasonic transducer technologies for nano surface reformation,

and milling process for high quality and high precision machining

Ultrasonic transducertechnologies using piezoelectric actuatorsfor

increasing the surface hardness, reducing the coefficient of

friction,and performing milling.

Client / Market

- Manufacturing system component supplier for displays, LEDs, and semiconductors

- Eco-friendly car and ship driving component manufacturer

Necessity of this Technology

- Surface profiles using conventional milling tools are very smooth, so it had difficulty in generating surface texturing.

- When nano surface reformation technology using ultrasonic vibration is applied to various equipment and machinery driving components, the cost can be reduced as the life is extended with driving property enhancement from reduced coefficient of friction and improvement of surface hardness.

- To improve the surface improvement effect, the ultrasonic power needs to be raised compared to existing technology, and for this, precision design and production technology of ultrasonic transducer and the tuning technology with oscillator were developed.

Technical Differentiation

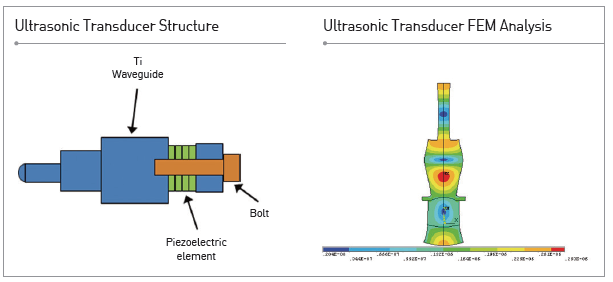

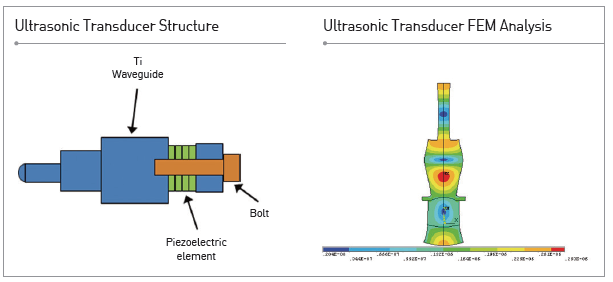

- Resonance design technology of the transducer and behavioral analysis technology are secured with behavioral analysis of the ultrasonic transducer using FEM.

- Ultrasonic transducer for nano surface improvement with bolt-clamped Langevin transducer (BLT) type was developed.

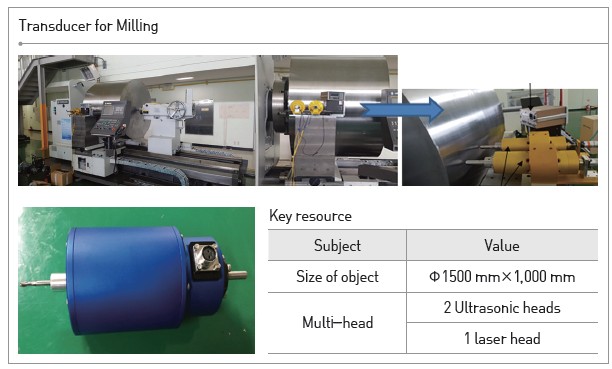

- Ultrasonic transducer for milling for high quality and high precision machining was developed.

Excellence of Technology

- Ultrasonic transducer for milling with surface texturing ability was developed.

- The surface hardness depth was 50 micro and the hardness value increased from 11.5 to 22.5.

- The coefficient of friction dropped from 0.02 to 0.017.

- Surface treatment depth was 85 micro-higher than 50 micro is considered a high value.

Current Intellectual Property Right Status

PATENT

- Ultrasonic Milling Machining Apparatus (KR1561531)

- Ultrasonic Milling Transducer (KR1632206)

- Machining Object Surface Treatment Apparatus Using Ultrasonic Transducer (KR1579943)

KNOW-HOW

- Ultrasonic transducer resonance property and sound field analysis technology using FEM

- Ultrasonic transducer design and fabrication technology

|