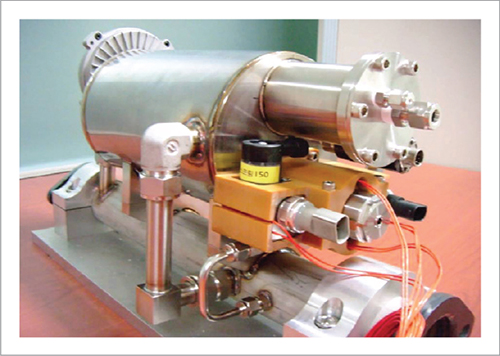

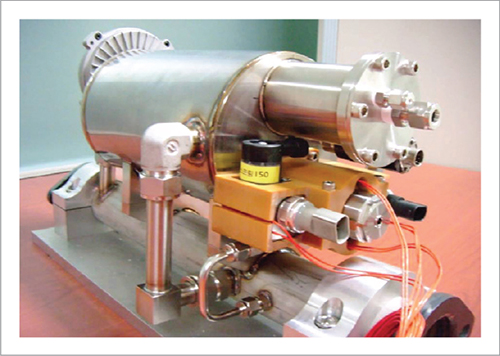

Technology for thermal decomposition of solid ammonium to generate ammonia gas to use as a reducer reducing agent for NOx emitted from an internal combustion engine

Client / Market

- Emission after-treatment system company for car, marine engine, agricultural machine, construction machine, etc.

Necessity of this Technology

- Existing liquid urea technology is very complex and expensive as it consists of a urea tank with defrost ability, corrosion prevention pump, regulator, temperature/ pressure sensor, injection valve, and supply pipe.

- Existing liquid urea technology uses the principle where urea water solution is injected to the exhaust pipe to make ammonia gas, therefore, a high-pressure injection using a well-designed nozzle is required, and sufficient distance from the injection point to the SCR inlet is necessary. However, most of the cars, ships and agricultural machines have an insufficient space for exhaust gas after treatment system.

- With liquid injection, low-temperature NOx reduction performance is low.

Technical Differentiation

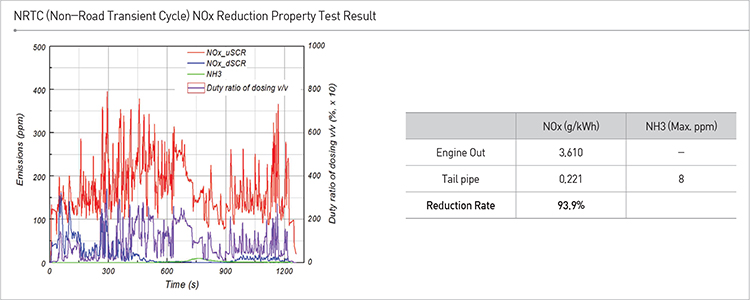

- It shows great low-temperature NOx reduction performance. (Liquid urea technology cannot be used when the exhaust gas temperature is below 200℃ due to deposit problem.)

- Theoretically, the solid ammonium has 3 times greater ammonia storage capacity compared to liquid urea.

- Since it uses gas injection, it needs less space and time to make ammonia gas. It is helpful for automobile or agricultural machine producer to develop related system designs.

- It uses a low-priced reducer reducing agent (ammonium carbonate or ammonium carbamate).

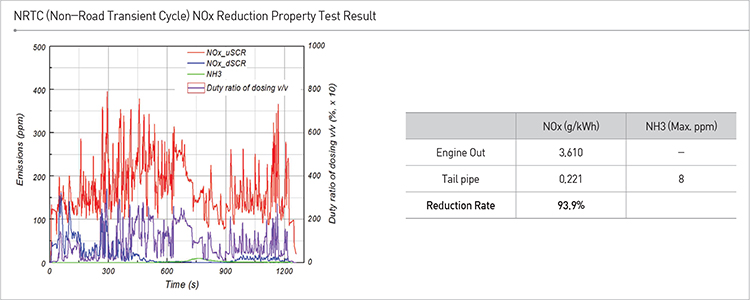

Excellence of Technology

- The system generates ammonia gas with low cost and low electric energy consumption.

- We have a lot of commercialized experiences about exhaust gas after-treatment system development, such as an exhaust filter system, during past 20 years.

Current Intellectual Property Right Status

PATENT

- A Reactor for Solid Ammonium Salt and Control Method Thereof and NOx Emission Purification System Which Using Solid Ammonium Salt and Selective Catalytic Reduction Catalyst (KR1436936, PCT/KR2013/011542, US14/382614, EP13863670.9)

- NOx Emission Purification System using Solid Ammonium Salt and Selective Catalytic Reduction Catalyst (KR1185413)

- Emission Purification System Using Solid Urea and Selective Catalytic Reduction Catalyst (KR0924591)

- Solid Urea Reactor and NOx Purification System Using Solid Urea and Selective Catalytic Reduction Catalyst (KR0999571)

- Exhaust Purification System (KR2012-0145178, US13/855113)

- Exhaust Purification System (KR2012-0145181)/Catalytic System for Exhaust Gas Purification (KR2013-0136264)

- An Ammonia Gas Generator by Using Solid Ammonium Salt (KR2013-0122062)

- Cartridge of Solid Ammonium Salt and Its Production Method (KR2013-0122177)

- After Treatment System with Solid Ammonium for Selective Catalyst Reduction (KR2014-0051606)

|