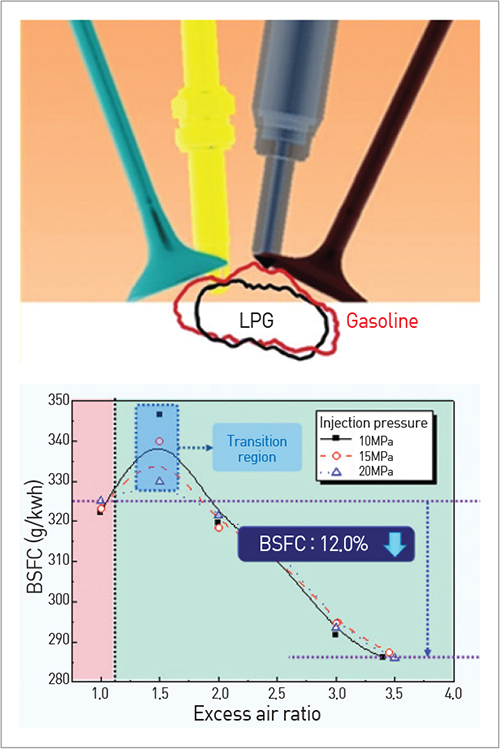

High-efficiency direct injection type ultra-lean LPG engine using spray-guided type combustion system

By locating the fuel injector in the center of the combustion chamber like a diesel engine and locating the discharge electrode of the spark plug in the recirculation zone of the spray to create a stable stratified lean mixture regardless of the operating condition of the engine to enable stable lean combustion through optimization of fuel injection strategy and ignition strategy. With this, highly efficient combustion is possible even under a very lean mixture condition, therefore, this next-generation engine technology can achieve fuel consumption reduction and high power output at the same time.

Client / Market

- Gas fuel (LPG, CNG) engine manufacturer

Necessity of this Technology

- Gaseous fuel like LPG and CNG is responsible for a large part of domestic transportation fuel, and with price relatively cheaper that gasoline and diesel, the number of registered vehicles using it exceeded 2 million in the late-2000s, and the number is still on the rise.

- Also, if the government adjusts the price of low-carbon gas fuel, which has relatively clean fuel image, to 50% of the existing gasoline and diesel fuel in consideration of the diversification of domestic energy sources and the social cost from environmental pollutants, the supply of natural gas vehicles is expected continue to increase.

- Low-carbon gaseous fuel such as LPG and CNG is beneficial as vehicle fuel seen from the aspect of easy fuel supply, improvement effect compared to the existing system, possibility of commercialization, and relative difficulty of technology development. However, until today, mainly the intake port injection method is being applied, therefore the limitations of premixed fuel combustion, that is, the limitation of pumping loss and ultra-lean combustion and the engine output and exhaust performance improvement effects due to the evaporation heat of fuel still need improvement. It is still insufficient to be used as an alternative in the future considering the CO2 emission regulations and energy efficiency aspects.

- In order to solve the problems of the premixed fuel combustion, direct injection technology in which the gaseous fuel is directly injected into the combustion chamber is considered to be one of the most important technologies for satisfying the emission regulations and CO2 regulations in the future.

Technical Differentiation

- The direct injection gas engine directly injects the gaseous fuel into the cylinder in the engine, which improves the accuracy of fuel control and lean combustion can be realized to maximize the combustion efficiency.

- In addition, due to the evaporating property of gaseous fuel, the temperature of the air is cooled, thereby suppressing abnormal combustion such as knocking, improving thermal efficiency by increasing compression ratio, and achieving high volumetric efficiency from direct injection to the cylinder. It has the advantage of reducing emission of harmful gas and maximizing energy efficiency, the key to CO2 emission, through enhancement of output and fuel economy.

Excellence of Technology

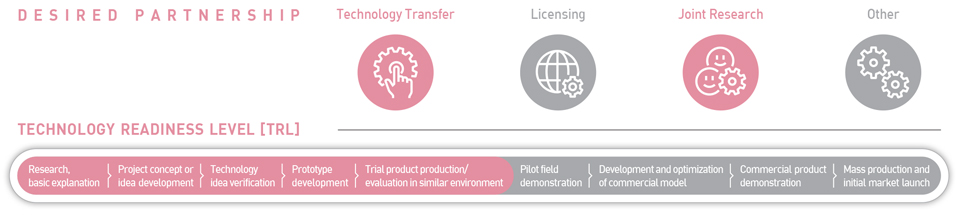

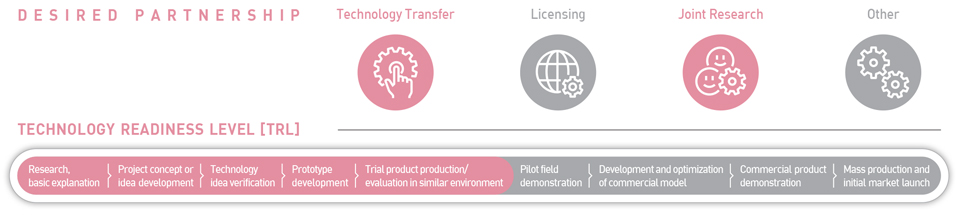

- 10% improvement in specific fuel consumption through development of core technology for ultra-lean direct injection gas engine

- Expansion of lean combustion operation through optimization of fuel injection control

- Performance and exhaust improvement through application of boosting system and EGR control system

Current Intellectual Property Right Status

PATENT

- Inter-injection Spark Ignition Control Method for Direct Injection Gas Engine (KR1615698)

- Direct Injection Gas Engine (KR1599473)

- Valve Operation Control Method for Preventing the Carbon Deposition of Spark Plug in a Direct Injection Gasoline Engine (KR1226058)

- Temperature Stratification Method for Anti-knocking in a Direct Injection Gasoline Engine (KR1299688)

KNOW-HOW

- Gaseous fuel high-pressure fuel supply and ignition control technology

- Ultra-lean mixture engine’s combustion stability control technology

- Direct injection fuel injection time and injection fraction optimization technology

- Engine optimized control by operating condition and EGR/boost control technology

|