Technology for the development of a big-size injector that is a core device in fuel supply system of a MW-size internal combustion engine fueled with methane-based gas such as natural gas, shale gas and bio-gas etc. The moving part is opened by the electromagnetic force generated from the solenoid and closed by the pressure difference and the spring force. The high flow rate methane-based gas fuel injection valve features a specific shape of flow channel.

Client / Market

- MW-class gas engine production company (for ship and power generation)

- Retrofit company from large diesel engine to large gas engine (including a retrofit kit manufacturer and seller)

- Repair and maintenance company of gas engines for medium/large ships and power generation

Necessity of this Technology

- Existing injector has a confined area for flow channel and there is a limit for sufficient fuel supply.

- Because the leakage rate of existing high flow rate injector (4.8 L/min or less at the pressure difference of 0.7 bar) is large, an injector with a smaller leakage rate is needed.

- Expensive ferromagnetic material is used in the core and armature. Therefore, there is a need for an economically feasible material with great formability and durability that could fulfill required response time and flow rate.

- Injector capability that could guarantee stable stroke and flow rate with the same control signal is required.

Technical Differentiation

- Solenoid structure with maximized magnetic force by electromagnetic analysis and experiment

- Armature structure with minimal resistance and optimized stroke to secure quick responsiveness and sufficient flow rate

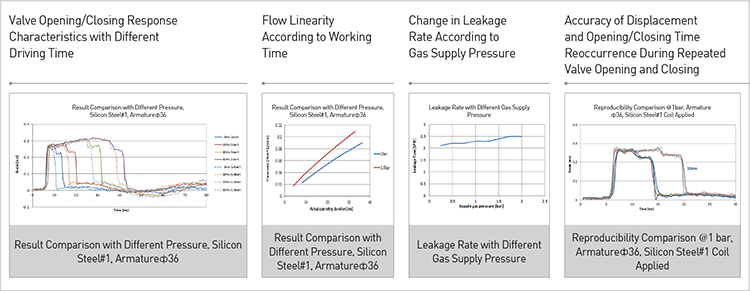

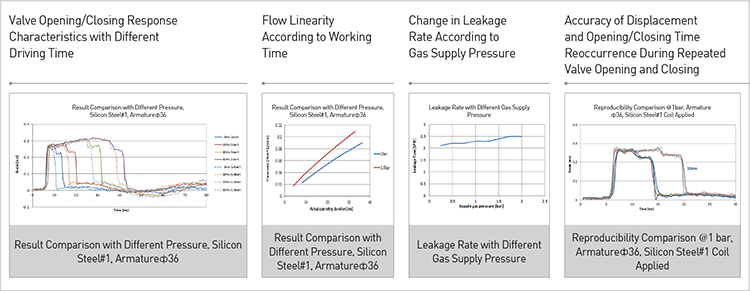

- Differentiation of injection valve driving characteristics according to the change in material of the solenoid core and armature (Silicon steel with strong magnetic force is appropriate for a case of high pressure difference)

- Aspecific shape of internal flow channel designed to guarantee high flow rate

- Consistent valve opening and closing responsiveness matching with stroke regardless of repetitive injection valve operation

- Minimized valve leakage through improvement of lower outlet design by replacement of O-ring

- Monitoring and control function for the high flow methane-oriented gaseous fuel injector

- Measurement of stopper abrasion and spring elasticity change using shock and oscillation detection in the acceleration sensor for injector maintenance and selfdiagnosis of error

Excellence of Technology

- Valve response accuracy, reproducibility and flow rate linearity following the control duty ratio

- Injection valve opening and closing responsiveness within 2 ms

- Ultra-low leak injection valve with the leakage of 2 to 3 L/min under the pressure difference of 0.2 to 2 bar

Current Intellectual Property Right Status

PATENT

- An Injection Valve for the Methane-Oriented Gaseous Fuel (KR1570492)

- A Monitoring and Control Method of Injection Valve for the Methane-Oriented Gaseous Fuel (KR1674994)

KNOW-HOW

- High flow methane-oriented gaseous fuel injection valve design technology

- High flow methane-oriented gaseous fuel injection valve control technology

- Methane-oriented gaseous fuel injection valve breakdown diagnosis technology

|