Nano-convergence Manufacturing Research Division

The Nano-convergence Manufacturing Research Division develops nano-convergence technology for future production by developing core technologies and conducting commercialization research.

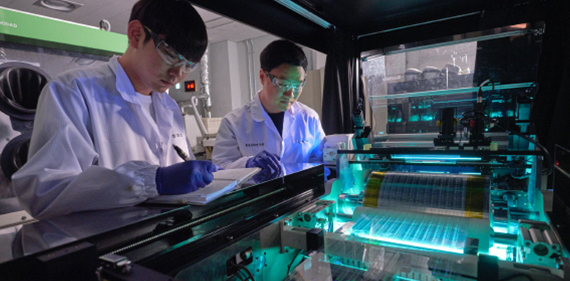

Nano-lithography & Manufacturing Research Center

Research Topics

- Nano-imprint lithography processes and equipment

- High-resolution digital lithography processes and equipment

- Ultra-precision machining and molding process and device fabrication

Major Achievements

Nano-imprint lithography equipment and world-first nano-scale embedded artificial lensOffers a cost-effective alternative to traditional optical and electron-beam lithography for creating nano-scale structures on various substrates. This technology utilizes pre-fabricated stamps engraved with nano-patterns to precisely fabricate nano-scale structures directly onto various surfaces, including silicon wafers, glass, and plastic, and is suitable for high-resolution pattern formation and mass production. Nano-imprint lithography plays a crucial role in manufacturing high-performance semiconductor chips, developing nano-scale medical diagnostic devices, and producing high-resolution displays, providing significant cost and time savings over older technologies.

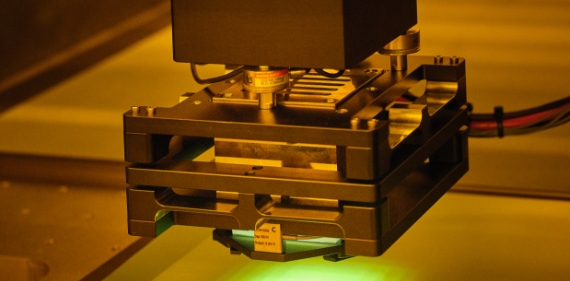

Department of Nano-devices and displays

Research Topics

- Next-generation freeform display design and manufacturing equipment technology

- Nano-materials and -devices design, fabrication, and measurement technology

- Meta-structures and meta-structure applications design, fabrication, and measurement technology

Major Achievements

Freeform micro-LED display technologyDeveloped core technology for freeform micro-LED displays that display undistorted images using roll transfer technology and related energy sources based on nano-materials and -devices.

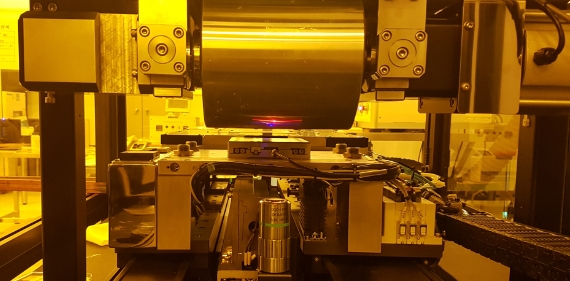

Department of Advanced Battery Manufacturing Systems

Research Topics

- Next-generation secondary battery and flexible electronic component manufacturing processes and equipment technology

- Intelligent roll-to-roll printing and coating processes, equipment, and digital transformation technology

- Core advanced battery and flexible electronics technology

Major Achievements

Roll-to-roll-based next-generation battery manufacturing equipment technologyDeveloped roll-to-roll control, multi-stage calendering equipment, and ultra-precision alignment technology for the precise, large-area production of next-generation secondary batteries and digital conversion technology for secondary battery manufacturing equipment using machine learning-based digital twin technology. In addition, we improved lithium anode stability by suppressing lithium dendrite growth.