- Created2022.10.11

The World’s First Successful Integrated Measurement of Exhaust and Non-exhaust

Particulate Matter (PM) Emissions of Various Vehicle Types

- Expected to provide guidelines to develop policies to mitigate non-exhaust PM emissions emitted

from internal combustion engine and electric vehicles -

The world’s first attempt to measure particulate matter (PM) emissions generated by not only engine combustion but wear-down of brake and tire is complete.

The Korea Institute of Machinery and Materials (President Sang Jin Park, hereinafter referred to as KIMM), an institute under the jurisdiction of the Ministry of Science and ICT, announced that it has succeeded in integrated experimental measurement of exhaust (engine combustion) and non-exhaust (tire and brake wear, road wear, and re-suspended road dust) emissions from the internal combustion engine and electric vehicles.

Until now, research on measuring the amount of non-exhaust PM emissions or identifying the phenomenon has rarely conducted except for brake wear PM emissions. When estimating total PM emissions, superficial methods have been used using emission factors correspondent to each emission source listed in the national emission inventory.

It is the world’s first attempt by KIMM to measure the total PM emissions according to vehicle type and sources through integrated experimental measurement. The result of this study will be used to identify the cause of the non-exhaust emissions from internal combustion engine and electric vehicles and to develop guidelines for government policies to mitigate traffic-related PM emissions.

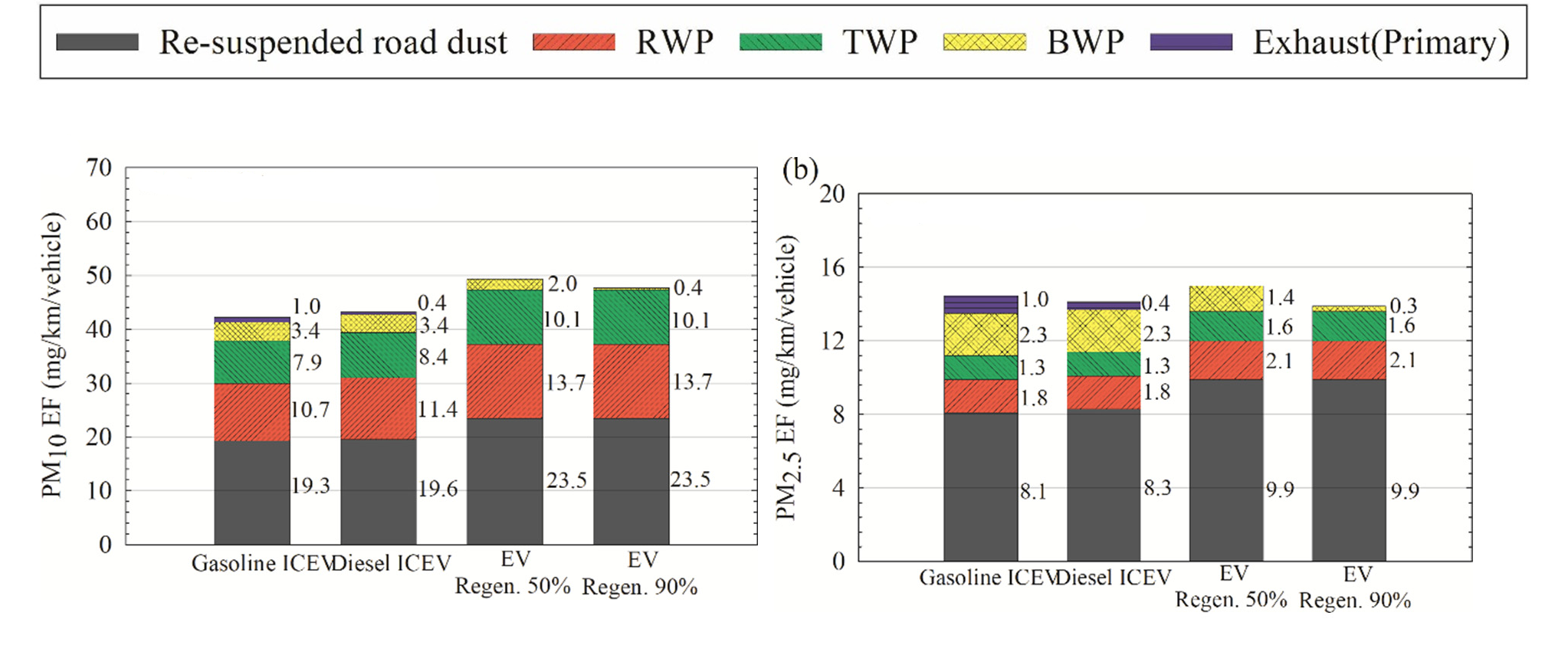

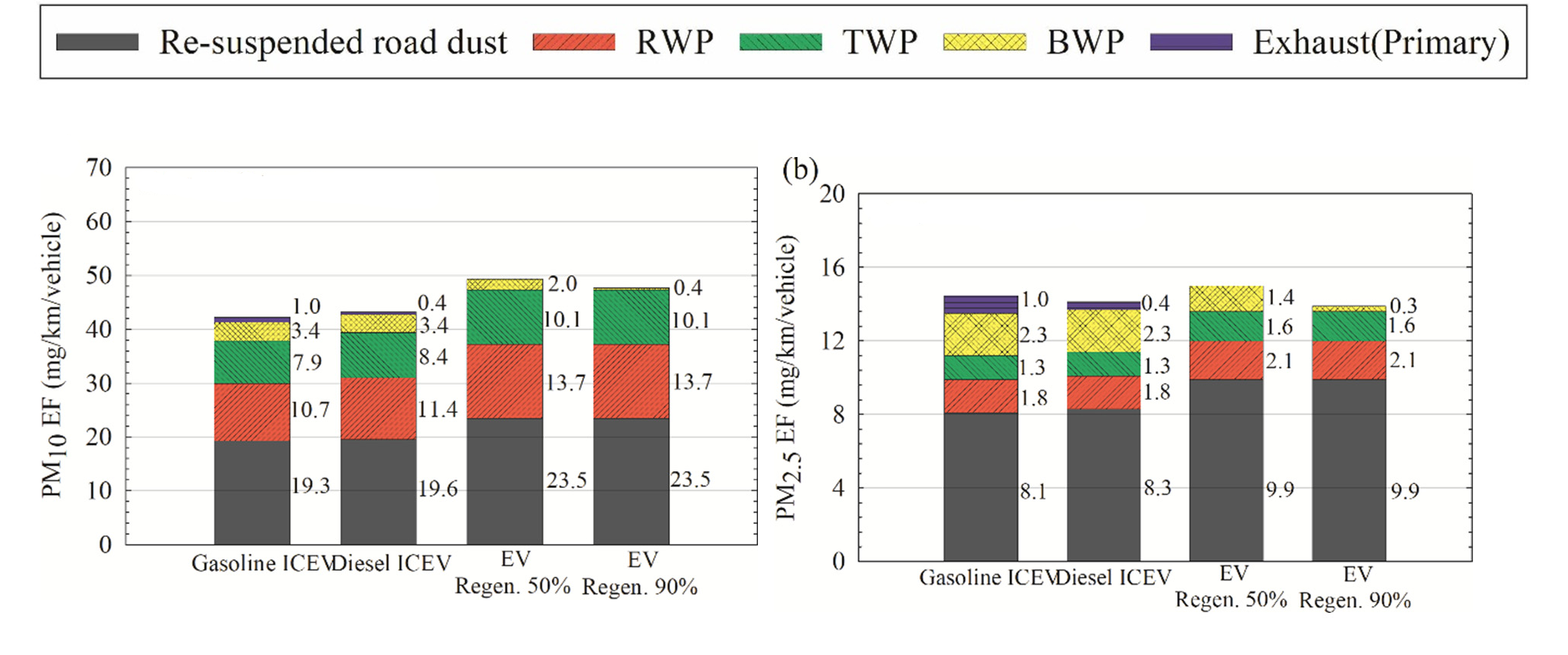

Dr. Seokhwan Lee and his research team in the Department of Mobility Power Research at the KIMM Institute of Carbon Neutral Energy Machinery conducted an integrated experiment and measurement of PM emissions according to the powertrain type for compact SUVs using an in-house developed tire wear simulator, brake wear simulator, and a mobile road dust measurement vehicle. The results for gasoline, diesel, and electric vehicles were as follows. PM10 emissions were 42.3 mg/km for gasoline vehicles, 43.2 mg/km for diesel vehicles, and 47.7 mg/km for electric vehicles. PM2.5 emissions were 14.5 mg/km for gasoline vehicles, 14.1 mg/km for diesel vehicles, and 13.9 mg/km for electric vehicles.

[Attachment 1] Images of compact SUVs used in this study (gasoline, diesel, electric vehicle)

[Attachment 2] The comparison of total PM emissions emitted from internal combustion engine and electric vehicles

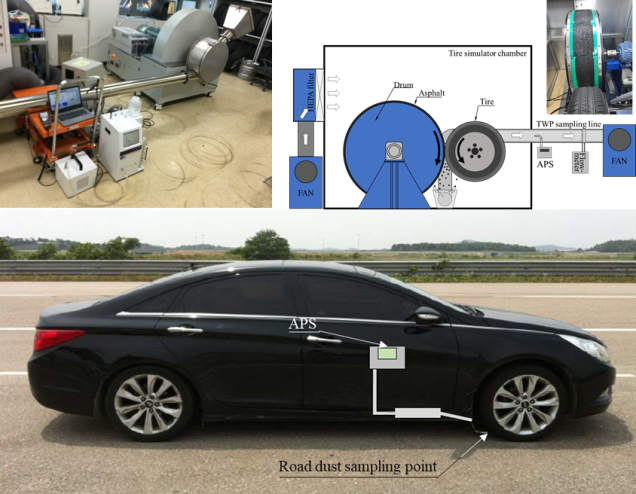

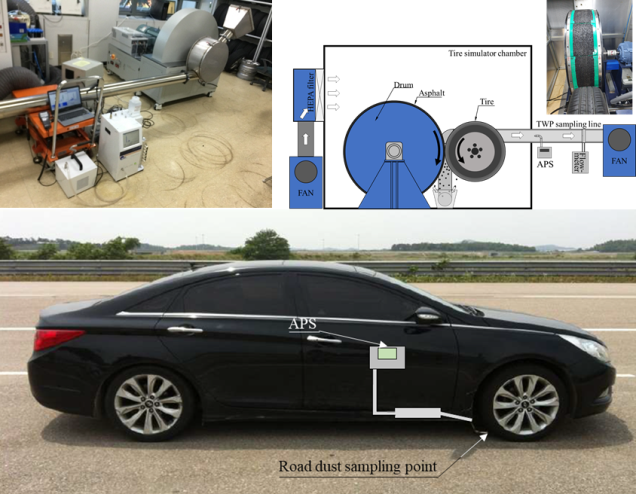

[Attachment 3] The brake wear simulator, tire wear simulator, and a mobile road dust measurement vehicle

used to measure non-exhaust emissions

According to Dr. Lee, “Electric vehicles do not emit toxic exhaust gases and greenhouse gases at all. Nevertheless, our results show that they do emit a significant amount of non-exhaust emissions.” He added, “To improve urban air quality, the government should parallelly implement various policies to mitigate non-exhaust emissions, rather than only focusing uptake of the electric vehicles.”

[List of Attachments]

- Attachment 1: Photos of compact SUVs used in this study (gasoline, diesel, electric vehicle) (Photos)

- Attachment 2: The comparison of total PM emissions emitted from internal combustion engine and electric vehicles (Image)

- Attachment 3: The brake wear simulator, tire wear simulator, and a mobile road dust measurement vehicle used to measure non-exhaust emissions (Photos)

The Korea Institute of Machinery and Materials (KIMM) is a non-profit governmentfunded research institute under the Ministry of Science and ICT. Since its foundation in 1976, KIMM is contributing to economic growth of the nation by performing R&D on key technologies in machinery and materials, conducting reliability test evaluation, and commercializing the developed products and technologies.

The research was conducted with the support from a project under the Ministry of Science and ICT, titled “Investigation of Physicochemical Characteristics of Traffic-related Particulate Matters”. The result of this study was published in the SCI journal Science of the Total Environment.

|

Credit: The Korea Institute of Machinery and Materials (KIMM) Usage Restrictions of Multimedia (Attachment File): The sources of photos and research results from KIMM must be specified |

- Attachment 1: Photos of compact SUVs used in this study (gasoline, diesel, electric vehicle) (Photos)

Description: Dr. Seokhwan Lee in the Department of Mobility Power Research at the Korea Institute of Machinery and Materials developed an integrated measurement method that measures both exhaust and non-exhaust PM emissions emitted from internal combustion engine and electric vehicles. This measurement was conducted based on the direct experimental analysis for the first time in the world. The test vehicles for the PM measurement share the same vehicle body (compact SUV), but with different powertrain, such as gasoline engine, diesel engine, and electric motor.

- Attachment 2: The comparison of total PM emissions emitted from internal combustion engine and electric vehicles (Image)

Description: The measurement of PM emissions of internal combustion engine and electric vehicles with 90% of regenerative braking intensity, the PM10 emissions of gasoline vehicle, diesel vehicle, and electric vehicle were 42.3 mg/km, 43.2 mg/km, and 47.7 mg/km, respectively. PM2.5 emissions were 14.5 mg/km for gasoline vehicle, 14.1 mg/km for diesel vehicle, and 13.9 mg/km for electric vehicle. Under the 50% of regenerative braking intensity, electric vehicle has emitted up to 15% more PM10 emissions compared to the internal combustion engine vehicles. However, the study estimates that PM10 and PM2.5 emissions of an electric vehicles are reduced by 15% and 50%, respectively, compared to the internal combustion engine vehicles, when we consider the secondary PM emission from engine combustion. As mentioned above, the current exhaust system in internal combustion engine vehicles has emitted significantly lower PM emissions with the help of modern technological advancements in engine combustion and after-treatment devices. The study found that more than 90% of PM emissions from internal combustion engine vehicles were originated from non-exhaust sources.

- Attachment 3: The brake wear simulator, tire wear simulator, and a mobile road dust measurement vehicle used to measure non-exhaust emissions (Photos)

Description: For this research, the current technological instruments are applied to accurately measure non-exhaust emissions according to vehicle type. Tire wear simulator, brake wear simulator, and mobile road dust measurement vehicle were utilized to measure the PM emissions from tire wear, brake wear and resuspension of road dust.