- Advanced Manufacturing Systems Research Division

- Nano Convergence Manufacturing Systems Research Division

- Innovative Energy Machinery Research Division

- Eco-Friendly Energy Conversion Research Division

- Mechanical Systems Safety Research Division

- AI Robot Research Division

- Daegu Research Center For Medical Devices&Green Energy

- Busan Machinery Research Center

Research Institute of Autonomous Manufacturing

The Research Institute of Autonomous Manufacturing conducts research on manufacturing equipment and process technologies to foster innovation and advance autonomous manufacturing. We combine cutting-edge manufacturing technologies with digital twin, AI, monitoring, diagnostic, and autonomous operation technologies to revolutionize manufacturing efficiency and flexibility.

Semiconductor Manufacturing Research Center

Research Topics

- Advanced semiconductor packaging processes and equipment

- Semiconductor FAB processes and equipment

- Autonomous semiconductor manufacturing technology

- Plasma source for chemical, environmental, and energy applications

Major Achievements

Wafer-level 3D stack- and ultra-thin wafer-handling equipment and processes for semiconductor 3D packagingSuccessfully mass-produced HBM memory packages for the first time in South Korea by developing and leveraging technology allowing for the high-precision 3D stacking of chips on large-area wafers and the handling of ultra-thin wafers without damage

Department of Ultra-precision Machines and Systems

Research Topics

- Design and process technologies for ultra-precision machining systems

- Design, analysis, control, measurement, compensation, and monitoring technologies for precision manufacturing equipment

- Digital twin and automation technologies for autonomous manufacturing systems

Major Achievements

Virtual prototyping technology for manufacturing equipment based on digital twinsCreated digital twins that integrate the physical model of structure, control, and process to evaluate the behavior of actual equipment

Department of Laser and Electron Beam Technologies

Research Topics

- Optical modules and laser machine

- Industrial laser sources

- Laser/Electron beam process and system technology

- AI based process prediction, measurement, diagnostic, and control technology

Major Achievements

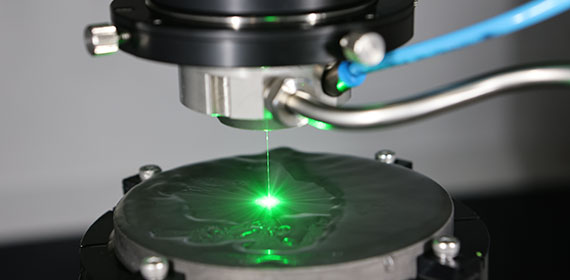

Water-guided laser hybrid machineUtilizes the total internal reflection of nanosecond laser pulses delivered through a laminar-flow stream of water with a diameter of 50–100 μm and a length of over 50 mm. Features an embedded 3D beam auto-stabilizing system, allowing the machine to operate autonomously for long periods.

Department of 3D Printing

Research Topics

- Core components for additive machine

- Intelligent additive processes and autonomous additive manufacturing systems

- DfAM(Design for Additive Manufacturing) and evaluation

- Convergence manufacturing based on additive processes

Major Achievements

Intelligent DED 3D printing system and process for large-part manufacturing/repair to improve functionalityDeveloped a large directed energy deposition system and process technologies that feature integration of machine, process control, and CAM S/W, which improved the functionality of press mold, defense system component, and space vehicle engine component.