- Created2025.05.29

Development of an Ultra-Light Robotic Prosthetic Hand with

Enabling Efficient and Stable Grasping Through Simple Control

- High-efficiency Stable Grasping with Simple Control

- Securing Core Technology for Improving Robotic Prosthetic Hand Function and Weight Reduction

- Enhanced Grasp Stability and Energy efficiency

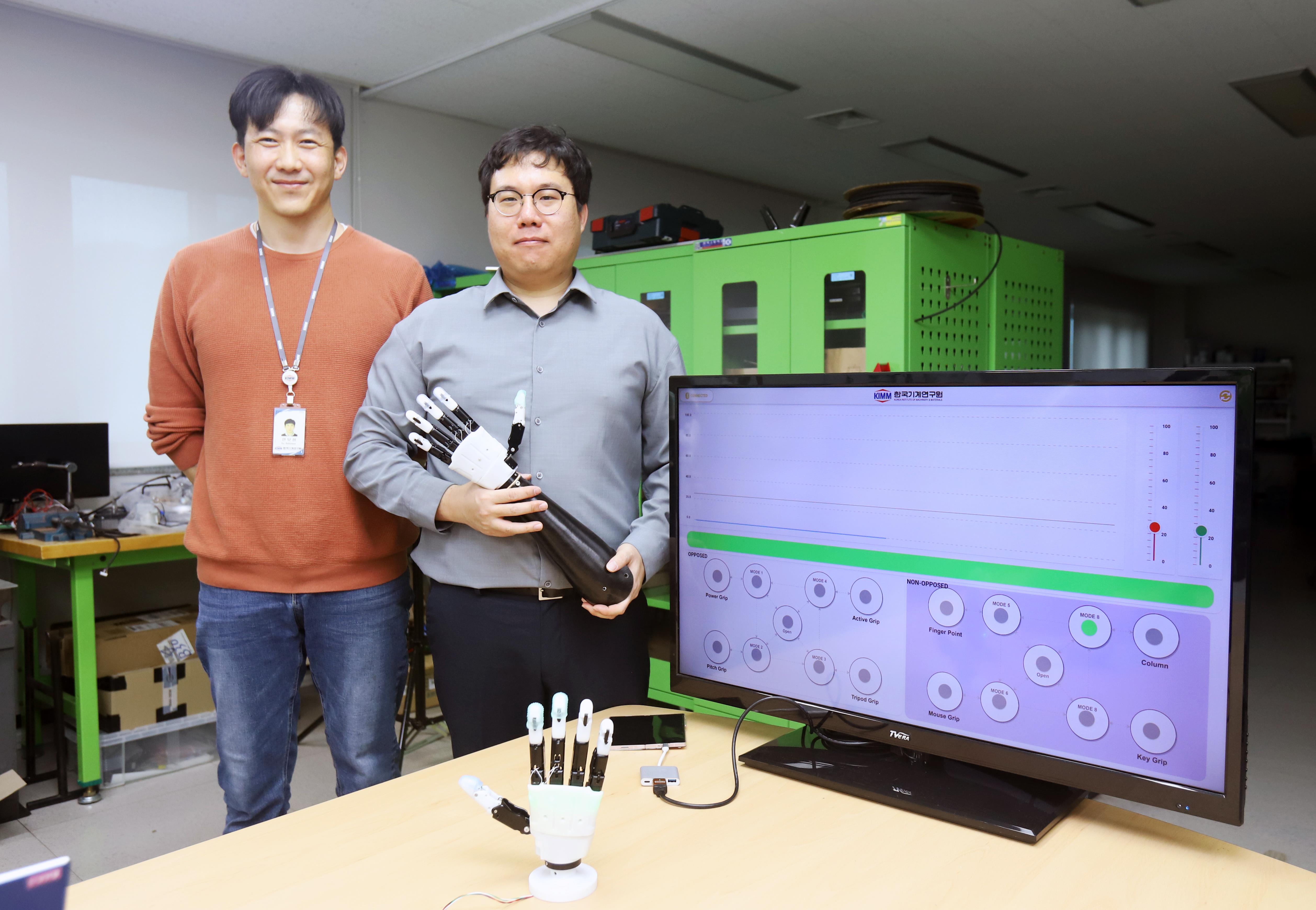

[The research team led by Dr. Minki Sin, Senior Reseacher of Department of Medical Robotics at KIMM]

(From left in the photo: Senior Engineer Bohyeon An, Senior Researcher Dr. Minki Sin)

□ The four-bar linkage system commonly used in conventional robotic prosthetic hands struggles to securely grasp objects of various shapes due to its fixed grasping trajectory. While wire-driven mechanisms provide better adaptability to object shapes, their sequential joint actuation characteristic reduces the stability of pinch grips and limits the naturalness of motion.

□ The linkage-wire hybrid mechanism developed by KIMM combines the strengths of both systems, offering the natural grasp trajectories and strong pinch grip of the four-bar linkage system, along with the shape adaptability of wire-driven system. The integration enables precise, efficient and stable grasping performance.

□ Additionally, the team developed an underactuated thumb by utilizing the intermittent motion* and dwell phase* of the Geneva mechanism, enabling a single actuator to independently control the thumb’s adduction-abduction and flexion-extension movements. While conventional products achieve thumb adduction-abduction through either passive joints or additional actuators—resulting in increased weight or limited functionality—this novel mechanism achieves both lightweight design and enhanced performance by enabling two degrees of freedom with a single actuator.

* Intermittent Motion: A drive method where rotation is performed stepwise rather than continuously.

* Dwell Phase: Interval in the Geneva mechanism where the actuator rotates but the Geneva wheel remains stationary.

[Photo of an ultra-light robotic prosthetic hand]

□ This technology enables amputees, who often struggle to generate precise control signals, to grasp various objects securely with simple motion commands. The proposed underactuated mechanism contributes to a lighter design, reducing the physical burden on users. Additionally, the shape-adaptive grasping enables more efficient interaction with objects, lowering energy consumption and extending battery life.

□ Patent applications for the core mechanisms have been filed, and the team is currently pursuing technology transfer and commercialization.

□ Senior Researcher Minki Sin stated, "This newly developed robotic prosthetic hand is expected to enable users to perform a variety of grasping tasks naturally and intuitively using only simple control commands, similar to how non-disabled individuals unconsciously execute detailed hand movements when grasping objects. Moreover, we are trying to apply the core technologies derived from this prosthetic hand to humanoid robots. While humanoid robots can generate a variety of control commands easily, the developed mechanisms of the prosthetic hand can help reduce computational load, and contribute to faster and efficient responses, enabling the development of more practical humanoid robots.“

[A validation test of the robotic prosthetic hand is being conducted by the research team led by Senior Researcher Dr. Minki Sin at KIMM]

□ This research was supported by the KIMM’s basic research program (“Development of human augmentation medical technology for upper/lower limb function recovery”) and the reserve fund project (“Development of a lightweight, multi-DOF robotic prosthetic hand with tactile feedback”).