- Created2021.03.17

New technique enables the production of 5 nmultra-small, porous, conductive nanoparticles

-Department of Nano-Mechanics of KIMM presents a new technique of producing ultra-small nanoparticles-

-Revolutionary improvement in productionpaves way for carbon neutrality-

The Korea Institute of Machinery & Materials (KIMM; President Sang Jin Park) under the Ministry of Science and ICT developed a technique of producing ultra-small porous nanoparticles from metal-organic frameworks (MOFs) using CO₂ laser-scribing at a rate tens of times faster than existing processes.

MOFs are compounds of metals and organic ligands and usually have a sponge-like porous structure. They show promise as an eco-friendly material as hydrogen or carbon dioxide can be stored effectively in their holes.

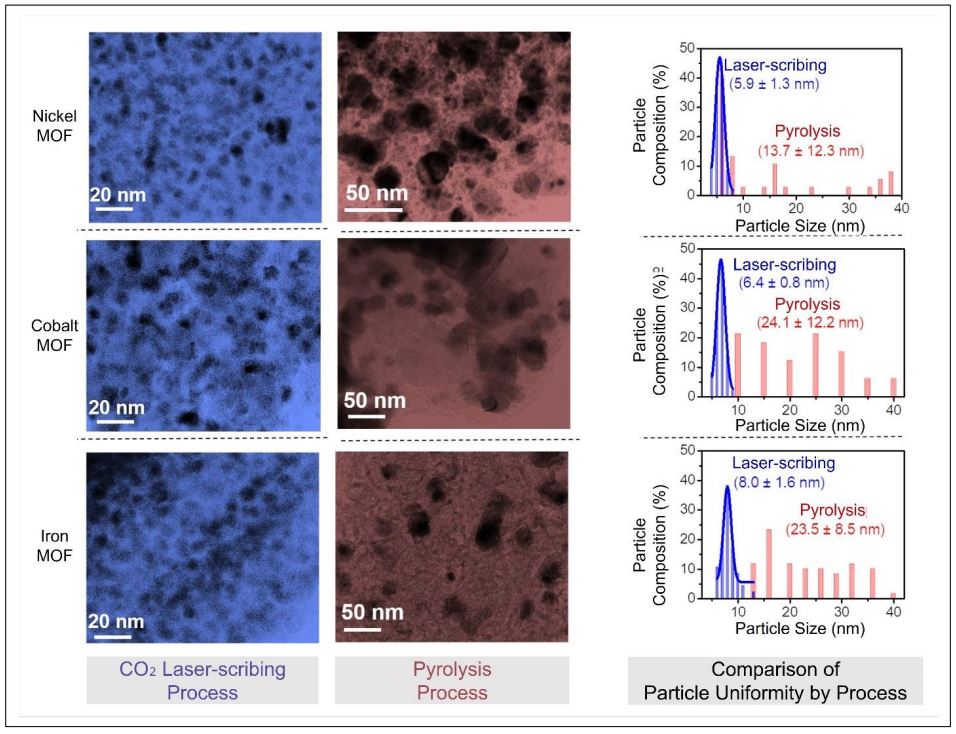

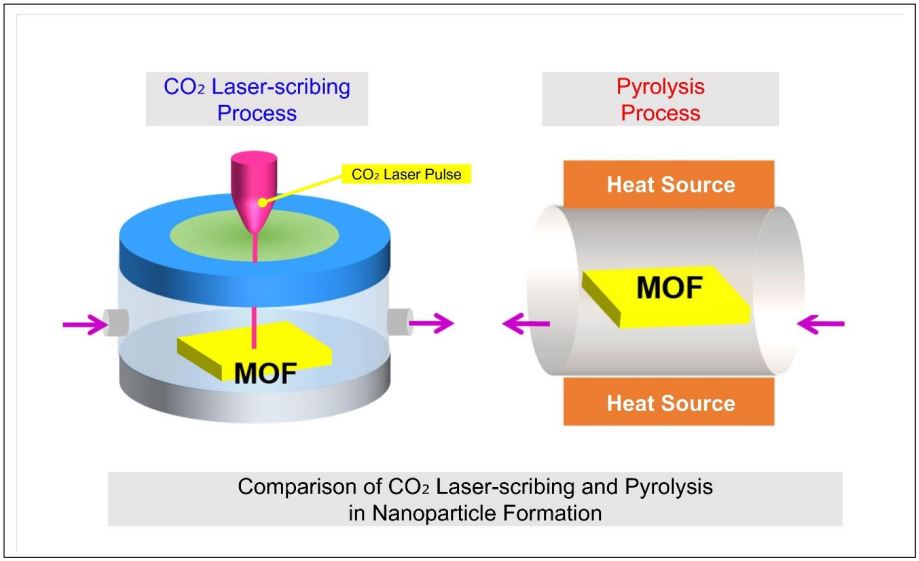

Seung-Mo Lee, principal researcher of the Department of Nano-Mechanics under the Nano-Convergence Manufacturing Systems Research Division of KIMM, succeeded in producing highly uniform 5 nm nanoparticles through CO₂ laser-scribing of MOFs. Carbothermic reduction occurs when MOFs are exposed to a CO₂ laser, and the instantaneous heating and extremely fast cooling result in the formation of small, uniform particles.

Previously, pyrolysis was employed, but it had disadvantages such as lengthy production time and limitations in reducing particle size. The team developed the technique of producing ultra-small, porous nanoparticles based on their extensive experience in CO₂ laser-scribing.

Principal researcher Seung-Mo Lee said, “The technique is expected to accelerate research on MOF-based nanoparticle production, including catalysts, energy storage, and CO₂ collection. We will continue to work hard for Korea to achieve carbon neutrality.”

The study was supported by KIMM’s “Development of Core Technology of Flexible Transparent Display Nano-based Production Equipment for Self-driving Cars” and the Ministry of Science and ICT’s “Development of Micro-LED-based Meta-display Technology,” and conducted jointly with the Korea Institute of Energy Research and the Center for Advanced Meta-Materials.

[List of Attachments] - Attachment 1: Comparison of CO₂ laser-scribing process and pyrolysis for the production of porous conductive nanoparticles (Image)

- Attachment 2: Schematic of CO₂ laser-scribing process for the production of porous conductive nanoparticles (Image)

The Korea Institute of Machinery and Materials (KIMM) is a non-profit governmentfunded research institute under the Ministry of Science and ICT. Since its foundation in 1976, KIMM has been contributing to the economic growth of the nation by performing R&D on key technologies in machinery and materials, conducting reliability test evaluations, and commercializing developed products and technologies.

The research, backed by both the Korea Institute of Machinery and Materials and the Ministry of Science and ICT, was conducted jointly with the Korea Institute of Energy Research and the Center for Advanced Meta-Materials.

An article explaining the results of this research was published in the latest issue of Chemical Engineering Journal (IF:10.652). (DOI: 10.1016/j.cej.2020.127731)

Credit: The Korea Institute of Machinery and Materials (KIMM)

Usage Restrictions of Multimedia (Attachment File): The sources of photos and research results from KIMM must be specified.

- Attachment 1: Comparison of CO₂ laser-scribing process and pyrolysis for the production of porous conductive nanoparticles (particle size and uniformity) (Image)

Image description: TEM images and graphs comparing the CO₂ laser-scribing process developed by Seung-Mo Lee, principal researcher of the Department of Nano-Mechanics at KIMM, and an existing pyrolysis process. The nanoparticles produced by CO₂ laser-scribing are smaller and more uniform.

- Attachment 2: Schematic of CO₂ laser-scribing process for the production of porous conductive nanoparticles (Image)

Image description: Schematic diagram comparing the CO₂ laser-scribing process developed by Seung-Mo Lee, principal researcher of the Department of Nano-Mechanics at KIMM, and an existing pyrolysis process. Heating and cooling take several hours in pyrolysis, but are instantaneous in laser-scribing, allowing ultra-small, uniform nanoparticles to be produced more rapidly.