- Created2019.05.21

New Equipment to Reduce Fine Dust from Coal Power Plants

-Successful development of a highly efficient Electrostatic Mist Eliminator (EME)by KIMM and Doosan Heavy Industries & Construction Co.-

-Reduction efficiency enhancedby a factor of tencompared toexisting equipment-

A new environment-friendly systemthat can remove the fine dust – created by coalfired power plants – to an emission level of 0.5 mg has been developed. Compared to existing equipment, this new equipment is ten times more effective at reducing fine dust and white plume, has a lower cost, and is easier to install in the flue gas desulfurization (FGD) systems of power plants.

The Korea Institute of Machinery and Materials (KIMM, President Chun Hong Park), together with the Doosan Heavy Industries & Construction Co. (CEO Geewon Park), has developed a highly efficient Electrostatic Mist Eliminator (EME). This EME can reduce the fine dust and white mist plume emitted from coal-fired power plants to a level of 0.5 mg/Nm3 level.

Principal Researcher Dr. Yongjin Kim and his research team (of the Department of Environmental Machinery, Environment System Research Division, KIMM) 2 combined the Mist Eliminator (ME) with an EME method that uses a novel electrostatic precipitation geometry with rigid plate discharge electrodes, optimized to enhance the removal efficiency by up to a factor of ten, even at high gas velocities of over 4 m/s.

This newly developed EME method is the world’s first ever technology to reduce fine dust emission concentrations to an emission level of 0.5 mg/Nm3 by simply replacing the existing ME located at the top of the Flue Gas Desulfurizer (FGD) with an EME.

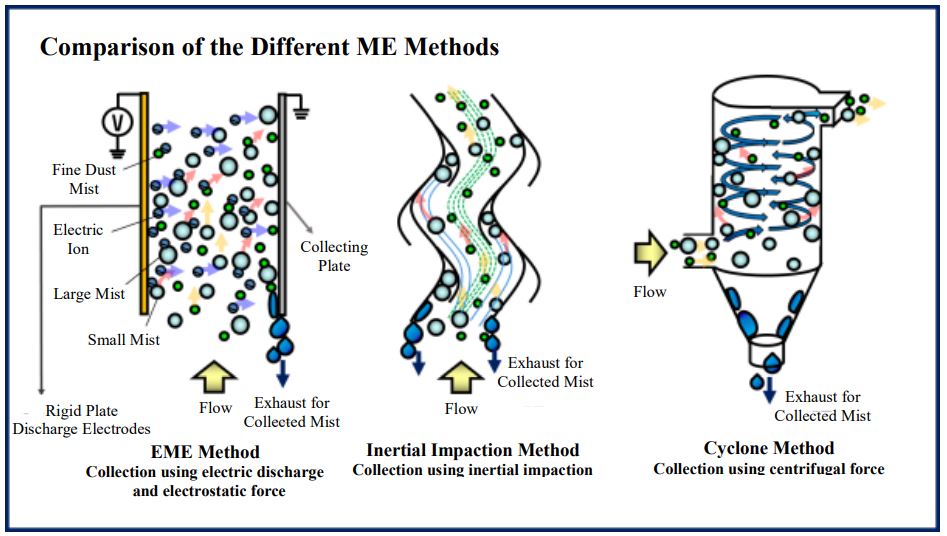

Existing coal-fired power plants have FGD installed directly on the chimneys. At the top of a FGD, a ME is installed to remove pollutant particles either by the cyclone method (removing pollutant particles using centrifugal force, by forcing them to move in a helical pattern) or by the inertial impaction method (removing pollutant particles using inertial impacts, by forcing them through zigzag-shaped pipes so that they hit the walls).

However, these methods struggle to remove particles under 20 µm diameter. To remove these smaller particles, power plant companies have to additionally purchase and install an expensive wet electrostatic precipitator, which increase their economic burden.

On the other hand, an EME can reduce the fine dust emission from coal-fired power plants to under 0.5 mg/Nm3 by simply adding the EME on top of the existing FGD without an additional wet electrostatic precipitator. This is considered as a world- 3 leading technology that allows to achieve an emission level less than 1/10 of the most stringent emission regulation (5 mg/Nm3 ).

KIMM, together with Doosan Heavy Industry & Construction Co., has built and successfully tested at Doosan Heavy Industry & Construction Co.’s factory in Changwon a 25 MW pilot EME, which can be applied to Korean coal-fired power plants. This pilot EME has the same physical dimensions as the commercial 500 MW EME, but treats a flue gas volume equivalent to a 25 MW plant. Doosan Heavy Industry & Construction Co. has also completed the commercialization design of a 500 MW EME, and is in discussion with major power companies in Korea to demonstrate this EME as an FGD retrofit at the old coal-fired power plants in Korea.

According to Dr. Yongjin Kim of KIMM, this new EME is “a world class technology that can bring down the emission concentration to levels equal or less than LNG power plants.” He also added, “We expect this technology to contribute to fine dust reduction within Korea via its application in large-capacity power plants and small to medium sized industrial units.”

Executive Vice President Yongjin Song of Doosan Heavy Industry & Construction Co. stated, “This EME, developed together with KIMM can provide an effective means to accomplish the recent objective of the Korean government to reduce the domestic fine dust emissions by 30%.” He also stated, “Doosan will continue its effort to develop environment-friendly technologies that can solve the existing problems of thermal power plants.”

Previously, in 2016, KIMM and Doosan Heavy Industry & Construction Co. were selected as the main institutions for the project ‘Development of AQCS Solution for PM10 Emission Control for Korean Standard and New Standard Coal-Fired Power Plants’ by the Korea Institute of Energy Technology Evaluation and Planning (KETEP) and the Ministry of Trade, Industry & Energy (MOTIE) of the Republic of Korea (No. 20161110100210).

The Korean government recently implemented an integrated management plan that aims to reduce domestic fine dust emissions by 30% by 2022 (compared to 2014). The Ministry of Environment is measuring on a real-time basis the flue gas emissions from all coal-fired power plants within Korea, and has the authority to stop power generation immediately if the emission levels exceed certain limits.

Attachments (High resolution images will be sent separately): - Attachment 1: Pilot EME at Doosan Heavy Industry & Construction Headquarter(Photos)

- Attachment 2: EME Operation Mechanism (Pictures)

- Attachment 1: Pilot EMEat Doosan Heavy Industry & Construction Headquarter(Photos)

Photo 1: Pilot EME for domestic coal-fired plants installed at the headquarter of Doosan Heavy Industry & Construction Co. (Changwon, Gyeongnam Province)

Photo 2: Pilot EME test run and efficiency monitoring conducted at Doosan Heavy Industry & Construction Co.(Changwon, Gyeongnam Province)

- Attachment 2: ME Operation Mechanism (Pictures)

Picture 1: At the chimneys of coal-fired power plants, Flue Gas Desulfurizers (FGD) are installed; the Mist Eliminator (ME) is installed on top of the FGD, to reduce the fine dust. Picture 1 shows the design of a ME using the inertial impaction method, which is used at 90% of domestic coal-fired power plants.

Picture 2: Picture 2 shows the operation mechanism of a ME at the end of aFGD. Currently most coal-fired power plants in Korea use the inertial impaction method, but this method has limitationsin removing very fine dust under 3-5 mg/Nm3 . This new EME method can remove fine dust at a level of 0.5 mg/Nm3.