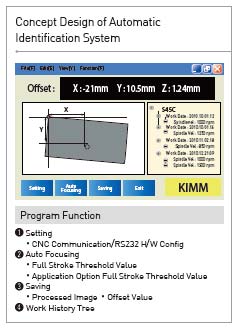

Chuck holder built-in machining origin for unmanned machining setup process

Automatic identification and simultaneous autonomous control module

Client / Market

- Machining-tool manufacturer/Machine-tools manufacturer

Necessity of this Technology

- Need for a mechanism to control the visibility of the built-in tool holder structure

- Automatic recognition & autonomous correction function/mechanism was

developed where vision and lighting module is built in on the tool holder enabling

on-machine measuring; automatic recognition of location and size of the specimen

for machining and the z-axis auto-focusing function enables autonomous

correction of the initial machining origin with 3-axis of width, length, and height to

suit the changed specimen (compares not only the width/length vision measuring

but also the thickness (height) of the material through visibility control)

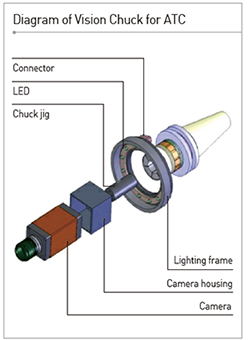

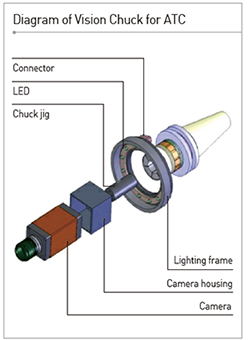

- To create a completely automatic line linked structurally to ATC, an exclusive tool

for inserting into the tool (or chuck) holder and a hollow cylinder DSP board (designed

to prevent eccentric force to suit the spindle machining tool structure) for lighting

device control were developed, and the firmware software was developed, mounted,

and built into the machine.

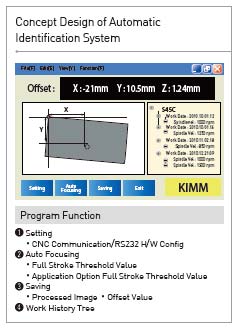

- Regarding specification, CNC-linked autonomous identification function with the

degree of precision of 0.09 mm and the sampling time within 1ms and CNC-linked

auto-focusing control function were promoted to be applied.

- Integrated chuck holder built-in module structure, the machining origin

autonomous identification mechanism, and CNC-linked on-machine autonomous

correction functions are required

Technical Differentiation

- From the control aspects, 3-axis automatic identification measurement + Z-axis

auto-focusing, autonomous correction control mechanism are linked (CNC-linked)

- From the structural aspects, the remodeled machining tool holder built-in chuck

type is applied.

- From the mechanism aspects, the new concept of measurement identification and

correction control through the visibility and lighting control is introduced.

- From the interface aspects, wired/wireless data high-speed/high-resolution data

collection and filtering is possible.

- Vision measuring tool is made to be built into the device like the automatic tool

changer (ATC)

- The setup or the mounted location of the inserted processing product in the onmachine

is detected by mounting the vision device onto the tool holder.

- Machining origin automatic identification following change of the material is

supported to realize unmanned machining through allowing the actual machine to

judge and measure.

(Accuracy and productivity are improved by excluding human workers, reducing the

setup time, and minimizing the error occurrence.)

| Distinctiveness |

Detail |

Current Global Status |

Goal of the Technology |

| Functional Aspect |

CMeasurementhina |

Touch sensor (only measurement) |

Non-touch vision measurement and z-axis autofocusing (simultaneous measurement + correction) |

| Applicable machining |

FMC machining |

Both FMC/RMC machining |

| Related commercial items/ flexibility |

No commercial item/No flexibility |

Possibility of application, commercialization/removable design (original) response 1:N machining possible |

| Method |

Operational aspect |

Semi-automatic |

ACTIVE TYPE Automatic and autonomous |

Excellence of Technology

- The automatic machine tool automatically identifies the machining origin for initial

machining (diversification of material) and reprocessing of existing processed

product to rid of the time required for setting the machining origin at the jog mode

for various forms and improve the setting accuracy of existing automatic machine

tool that depend on the initial setting; productivity is enhanced through separate

settings set automatically.

- Excellence of the technology has been proven by publishing (1 author) several SCIlevel

papers related or based on the technology on IEEE-ASME TRANSACTIONS ON

MECHATRONICS (within top 5% of SCI), JMST, IJPEM, Key Eng. (published on SCIlevel

journals multiple times)

- Has over 20 years of research experience in machine tool intellectualization and IT

integration.

- Received the 2013 Minister of Science, ICT and Future Planning Award (Scientist of

the Month Award), 2012 Korea Society of Mechanical Engineers Baekbong Technology

Excellence Award, 2011 KIMM Academic Award, and 2007 ICROS Academic Award.

CURRENT INTELLECTUAL PROPERTY RIGHT STATUS

PATENT

- TBuilt-in Type Vision Measuring Tool for Autonomous Machining Origin Setting

(KR2013-0117848, US13/533061)/Item Positioning Device and Positioning Method

(KR1106575)/Calibration Flaw Specimen Production Method (KR1140422)

KNOW-HOW

- Machine-tools pattern-matching based machining-origin identification technology

for processing machining-material change

- Unmanned autonomous setup and measurement technology in machining process, etc.

|