Device and module for surface texturing using micro milling, etc.

Client / Market

- Micro die and molds, ultra-precision machining system and components market

Necessity of this Technology

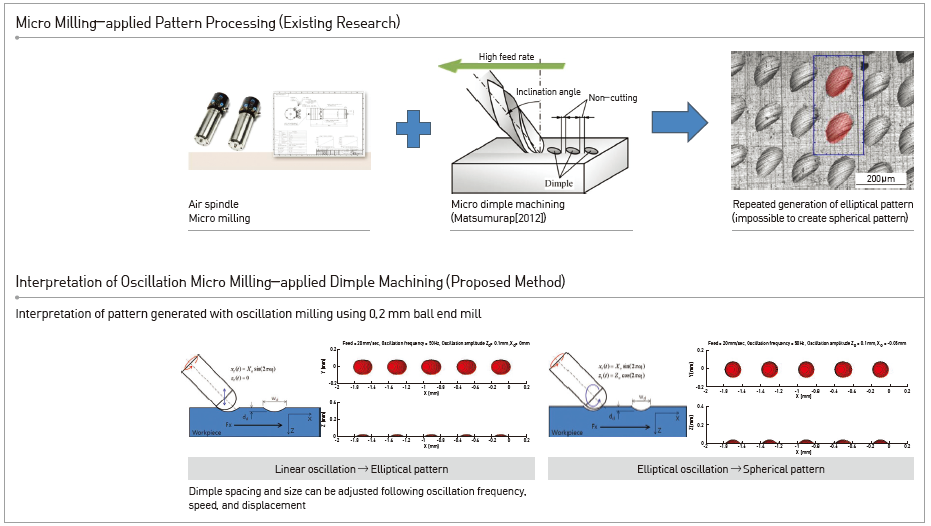

- Micropattern generation and texturing using cutting with a non-rotating tool

has limits regarding its form and processing direction; using milling/grinding

for texturing through feed control of the machine tool takes a long time and is

ineffective.

Technical Differentiation

- Texturing using milling does not limit machining direction; shorten processing time.

- Possible to generate various patterns using ball end mills and various tool

- Possible to apply various materials using micro milling

- Possible to generate patterns on a relatively large area using the grinding with prepatterned wheels

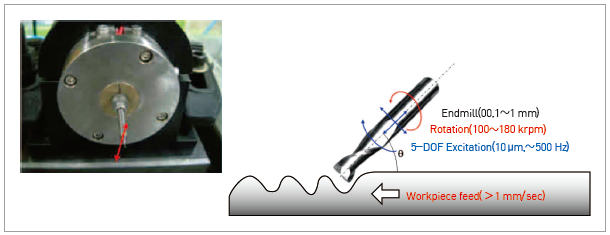

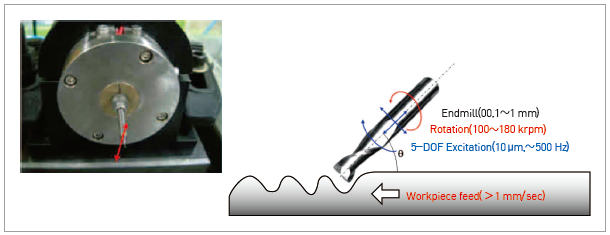

- Texturing using milling module that allows 5-DOF vibration displacement during rotation

- Micro machining using micro-patterned grinding wheels

Excellence of Technology

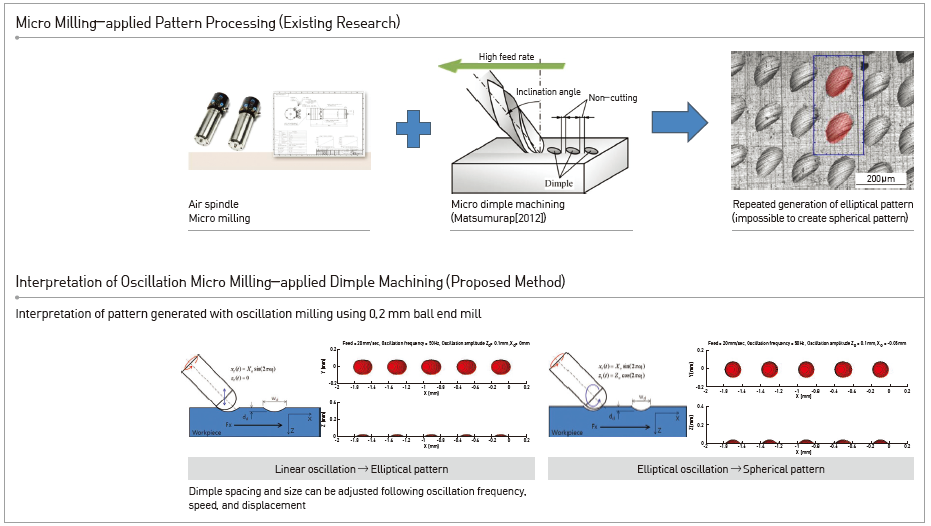

- Existing micro milling-applied dimple processing cannot realize spherical patterns.

- With this technology, repeated generation of spherical dimples expected to become

possible by synchronizing the work feeding speed.

Current Intellectual Property Right Status

PATENT

- Apparatus for Micro Surface Texturing Machining and Its Method (KR1463803)

- Grinding Apparatus for Surface Texturing and the Grinding Method thereof (KR1400876)

- Apparatus for Micro Surface Texturing (KR1476815)

|