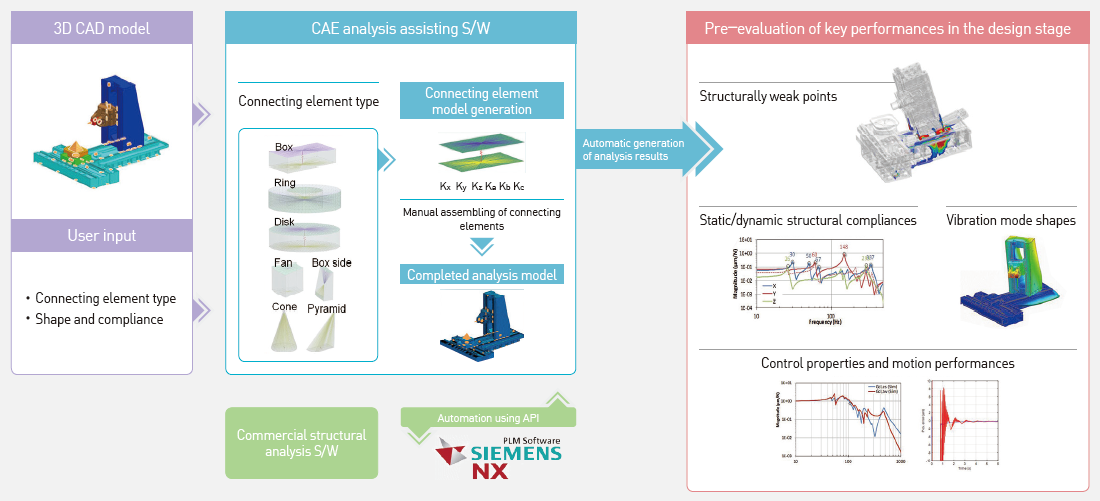

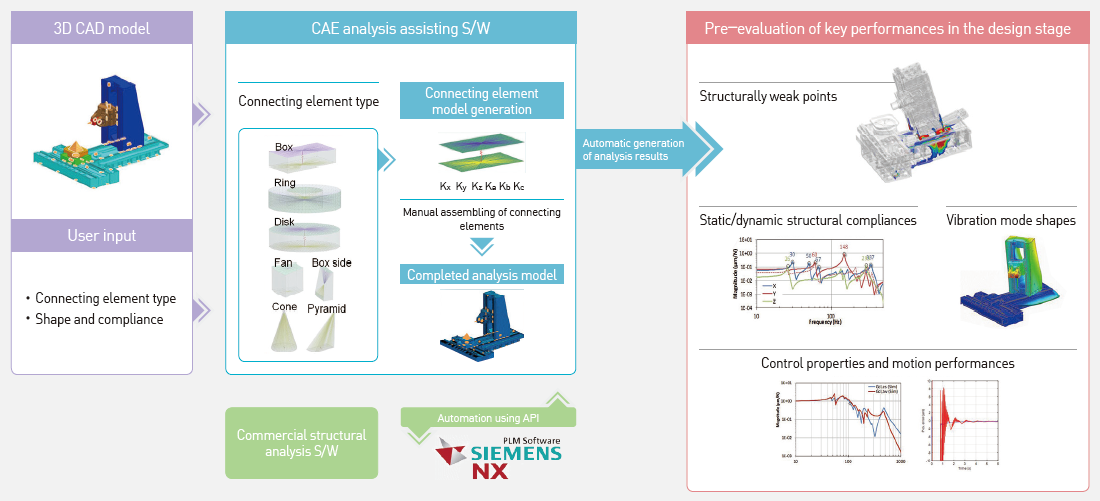

CAE analysis automation technologies to enable mechanical designers

to perform complicated CAE analysis of mechanical motion systems

Technologies to evaluate key performance indices of mechanical

motion systems by analyzing complicated CAE results

Client / Market

- Manufacturers of machine tools requiring high stiffness structure

- Manufacturers of high-speed, high-precision motion stages for semiconductor or

flat-panel display applications

Necessity of this Technology

- The CAE structural analysis is a widely used technique to evaluate the designs of

mechanical systems. However, evaluating the key performances of a complicated

mechanical motion system is too complicated for mechanical designers in SMEs.

- To secure reliability of the structural analysis result, connecting elements such

as LM blocks, ball screws, servo motors, and encoders should be modeled with

appropriate level of details and accuracy; which requires extensive know-hows and

empirical data.

- It is necessary to improve the availability of the structural analysis technology

by eliminating complex and labor intensive tasks including connecting element

creation and 3D geometry simplification.

Technical Differentiation

- Can evaluate the key performances of an entire mechanical motion system, not a

single unit or a part.

- Equipped with know-hows and empirical data to realistically model mechanical

connecting elements including LM blocks, ball screws, servo motors, and encoders.

- Manual work necessary for CAE structural analysis is minimized with automation

technologies.

Excellence of Technology

- A mechanical designer without expertise on CAE analysis can build the analysis

model of a complicated mechanical motion system with minimum user input thanks

to automation of complex processes of modeling connecting elements, geometry

simplification and assembly of finite element models.

- Once the primary structural analysis model is built, the same type of analysis can

be repeated in multiple positions automatically to evaluate the position dependent

performances.

- The basic structural analysis results are automatically processed into more

insightful performance indices, such as structural loop stiffness, gravity induced

machine accuracy, and motion performances.

Current Intellectual Property Right Status

PATENT

- Finite Element Analysis Techniques for Machine Tools (KR1729589)

- Vibration Transmission Analysis Method in a Precision Machine (KR1551183)

KNOW-HOW

- Analysis technology on gravity induced motion accuracy using static structural

analysis

- Component contribution analysis technology on static/dynamic structural stiffness

- Analysis technology on control and motion performances using structural analysis

results

|