Technology with patterning and thermal treatment process using

laser to produce precise fine die and reducing cost by minimizing

the use of film and chemicals compared to existing film work

Client / Market

- Flexible fine die manufacturer and semiconductor manufacturer

Necessity of this Technology

- Existing fine die manufacturing method of film work requires high initial investment

and material cost yet has low pattern precision and causes environmental pollution

with chemicals used during process.

- Due to complex process and need for film printer for film making, initial investment

is high. With massive use of films and chemicals used during process, the risk of

environmental pollution is high.

- Film work cannot precisely control the location; therefore, precision of patterning is low.

- To extend the life of flexible fine die and increase its solidity, heat treatment is

inevitable, but during this process, the die deformation may occur.

- There is a need for technology for creating a die at a low cost that allows precise

location control and does not deform during heat treatment.

- Required conditions include cost reduction, precise location control, and die

deformation prevention during heat treatment.

Technical Differentiation

- Production cost can be reduced as the process does not require film, developing

solution and other chemicals.

- Precise patterning is possible using laser, and the die defective rate is reduced as the life

and solidity of the die is extended without deformation caused during heat treatment.

- Harmful fluid used for film printing is not required; level of pollution at the manufacturing

site is improved leading to better work environment.

- The film method is replaced with the photocuring patterning method using laser,

which easily enables precise patterning on thin foil.

- Heat treatment using laser is done with laser scanner; therefore, flexible fine die

can be produced at minimal thermal deformation.

Excellence of Technology

- The laser photocuring process creates a polymer pattern of desired shape and

corrodes parts other than the pattern to create a bulging polymer pattern. With the

primary machining, a blade is added to the bulging part and the blade is made solid

with the secondary laser heat treatment.

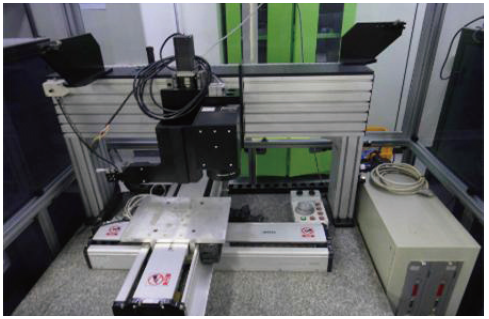

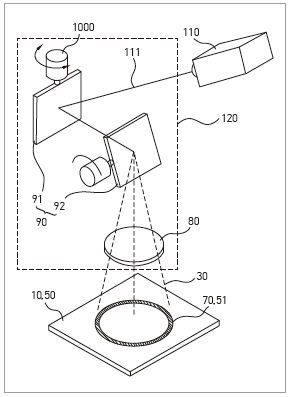

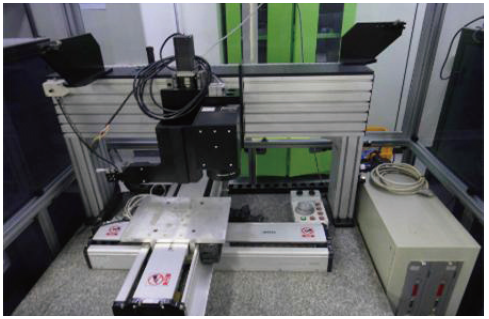

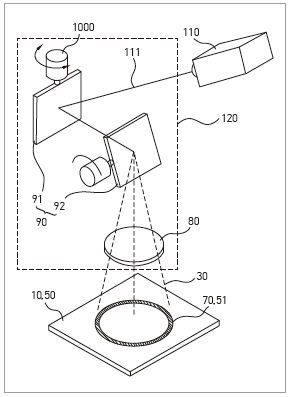

- Laser beam emitted from the laser generator (110) is reflected on to two rotating

reflectors (91, 92), which sends the laser to the die through the f-θ lens (80) to

perform laser heat treatment.

- By replacing the photocuring patterning process that requires films and various

chemicals and the heat treatment process requiring high-temperature heat with

the laser method. Above laser beam output can be adjusted from several hundred

Ws to several kWs.

- The head researcher has 20 years of research experience in printing field.

- As a part of ‘Customized Technology Service Project’ of Korea Research Council for

Industrial Science and Technology, the ‘laser heat treatment and printing for flexible

fine die’ technology was applied at a flexible fine die manufacturer, which was

proven to have cost reduction and environment improvement effect.

Current Intellectual Property Right Status

PATENT

- Flexible Fine Die Manufacturing Method Using Laser (KR2012-0002666)

|