Focus finding device with micro pattern technology on curved

3D surface using a different concept from existing confocal, WDI

method

Client / Market

- Laser machining equipment

Necessity of this Technology

- Various laser machining methods are used such as irradiating laser to the subject

to cut a furrow on its surface, to create a damaged layer inside, or to apply heat to

change its properties.

- The 3D curve measurement methods include using confocal or the WDI method,

however, since the machining laser’s focus position and the measuring laser’s focus

position are different, it is difficult to use them, and the optical components are complex.

Technical Differentiation

- Only uses one machining laser-therefore easy to find the focus position

- Simple optical components; able to monitor the status of machining laser

- Easy to find the focus position as there is no offsetting

- Simpler optical components compared to other methods

- Able to check the change in the machining laser (point stability, divergence angle)

- Able to check the change in the angle or roughness of the specimen

- Can be used on scanner

- Able to accurately line up the center of the printing roll and the center of the scanner

Excellence of Technology

- Does not use a separate measuring laser; only uses the machining laser to measure

the step height of the specimen

- After measurement, increase the laser power for machining (existing method

required a separate laser for measurement).

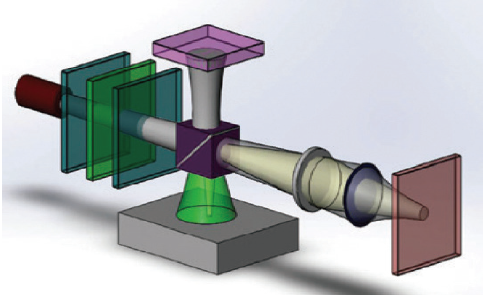

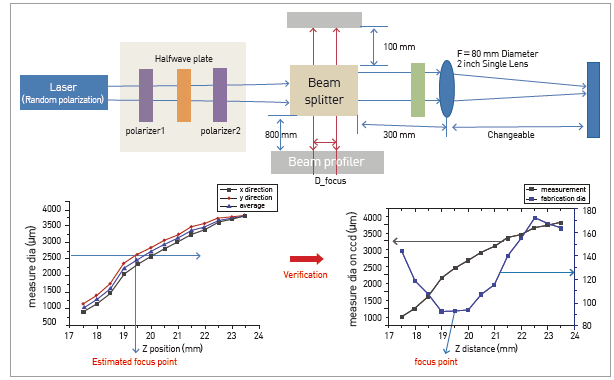

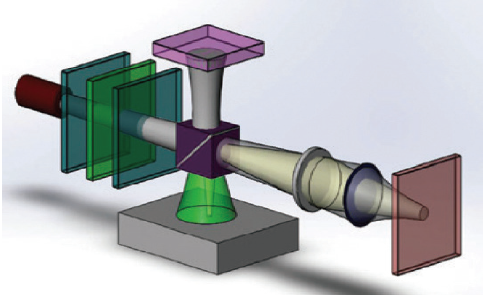

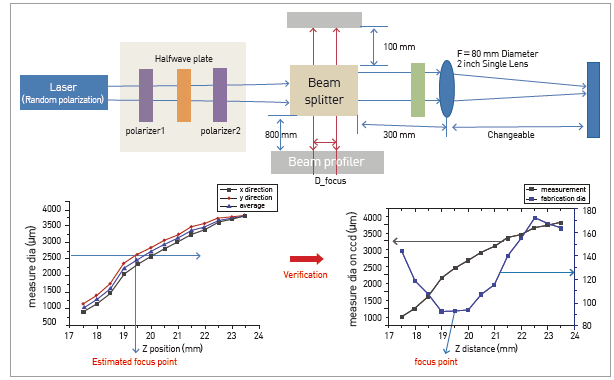

- Beam splitter splits the laser beam irradiated from the light source into reflection

beam and penetration beam, and the focusing lens concentrates the penetrating

beam to the subject of machining.

- Beam profiler receives the laser beam reflected from the subject and went through

the focusing lens and the beam splitter and measure the change in the beam profile

depending on the subject’s position change.

Current Intellectual Property Right Status

PATENT

- Laser Machining Device with Focus Measuring Function and Laser Machining

Method (KR2014-0097628)

-

- Laser Machining Device with Focus Measuring Function and Laser Machining

Method (KR2014-0097629)

-

- Laser Machining Device with Focus Measuring Function and Laser Machining

Method (KR1480162, PCT/KR2014/007026)

|