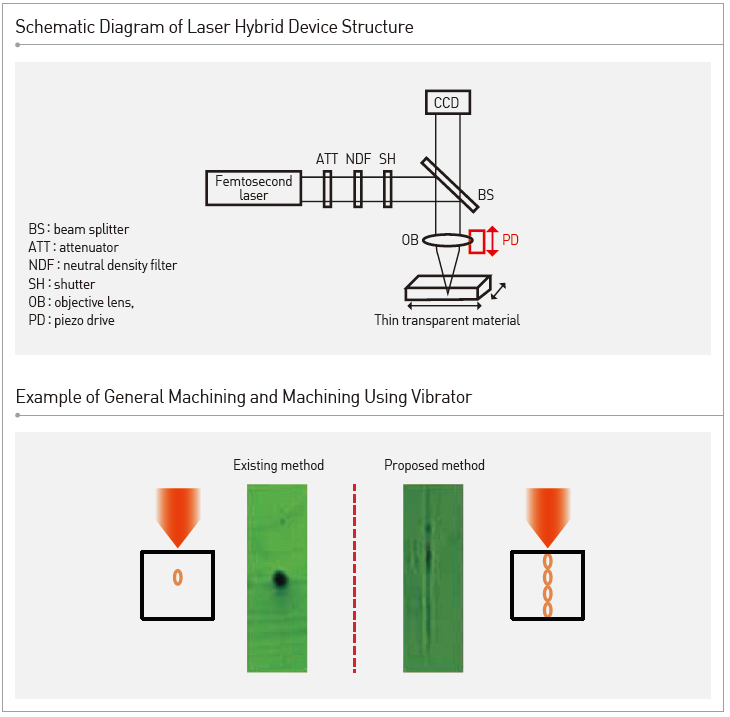

Femtosecond laser creates a micro-sized furrow or performs

drilling on all materials.

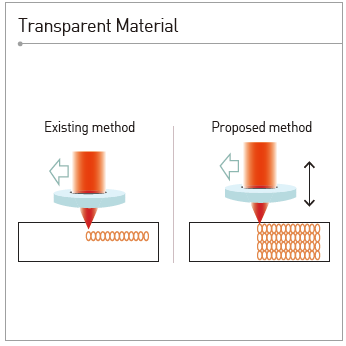

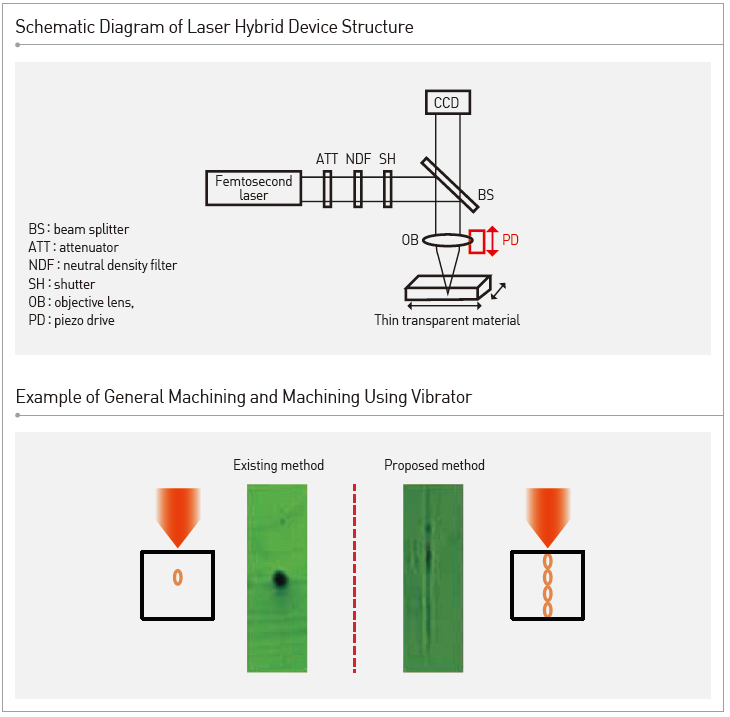

With the focusing lens rapidly vibrating, the micro-sized furrow or

drilling process efficiency increases.

Client / Market

- Companies interested in transparent material

Necessity of this Technology

- The goal is to simplification of the machining stages and improvement of machining

quality.

- There are limitations with mechanical process and quality for machining of

transparent materials such as glass and sapphire plates.

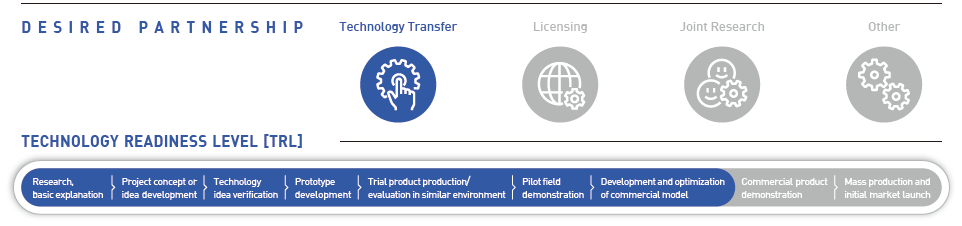

- When attempting to machine transparent substance using a general laser,

machining does not work as the laser beam penetrates through the substance or

creates an unnecessarily large crack.

- An alternative other than existing machining method for transparent material is

needed to realize simplified machining stages and higher quality.

Technical Differentiation

- Laser machining is a method using non-contact machining method, and compared to

mechanical machining, it can minimize unnecessary damage to the processed object.

- When machining a transparent object, due to the non-linear properties of

femtosecond laser, it enables deeper machining on the same axis in the direction of

clamping of focusing lens.

- One process achieves the effect of repeating several processes.

- When creating vertical vibration in the focusing lens of the femtosecond laser system

using a vibrator, the focus position is adjusted vertically, and by machining vertically

with this method, the part for machining on the object is intentionally extended in the

longitudinal axis direction. Unlike general laser cutting machining where the machining

restarts after focus adjustment, this process eliminates unnecessary steps.

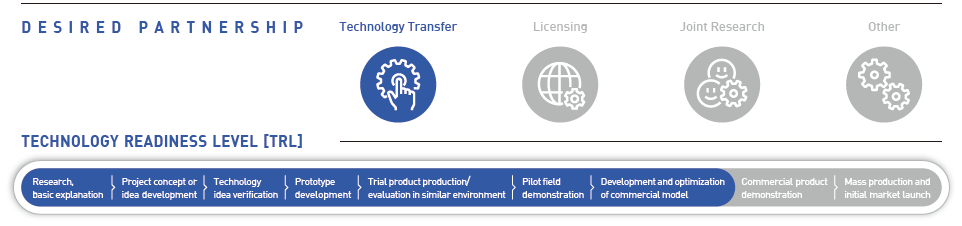

Excellence of Technology

- The machining process realizes longer machining on the part of the transparent

substance for machining in the longitudinal axis direction compared to the

machining method with the general laser machining system as it uses the non-linear machining characteristic of femtosecond laser and the vibration system of focusing lens with the vibrator.

- The method ultimately cuts the object by maximizing machining in the direction of depth.

- The head researcher for this technology has over 10 years of research experience in

ultrashort femtosecond laser-applied super-precision micro machining field.

Current Intellectual Property Right Status

PATENT

- Hybrid Laser Machining Device Using Vibrator (KR1273462)

- High Aspect Ratio Micro Shape Machining Device Utilizing Ultrashort Pulse Laser

(KR1285717)

- Selective Plate Thin Film Remover Using Laser Machining Technology (KR1285876)

- Hybrid Laser Machining Device Using Ultrasonic Vibration (KR1049381)

|