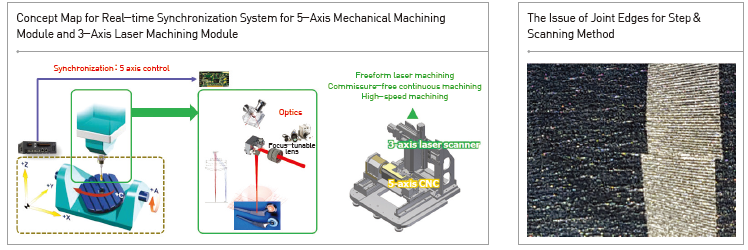

New breakthrough technology surpassing the limit of existing laser

machining area and speed through real-time synchronization of

5-axis mechanical machining module and 3-axis laser scanner

With this technology, micropatterning of size 15 μm at the continuous

machining speed over 280 mm/s can be performed on a freeform

surface.

Client / Market

- Functionality of home appliances/market requiring aesthetic surface, cellfriendliness

improving implant/hip surface treatment, cutting and boring of

automobile/aircraft surface component

- 5-axis cutting/boring laser machining market, real-time synchronization controller

market, laser CAM SW market

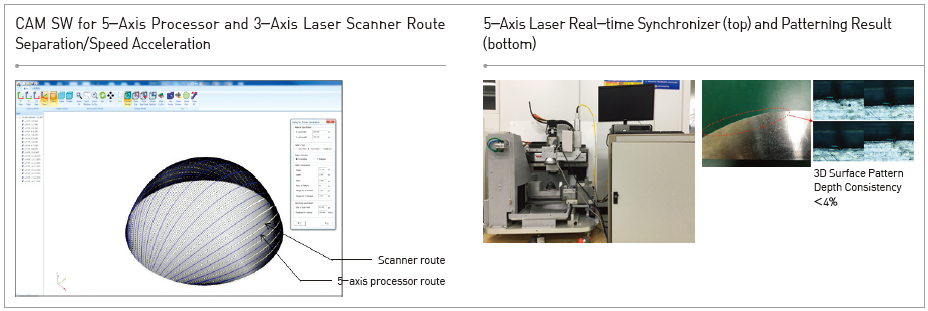

Limitation of Existing Technology

- 3-axis laser scanner cannot cope with a completely freeform due to the depth factor

of process.

- Foreign machine tool companies commercialize a simple combination of 5-axis

processor with 3-axis scanner.

- The manufacturing speed decreases and a commissure issue occurs with the step

and scanning method used with a simple combination of 5-axis processor and

3-axis laser scanner.

Technical Differentiation

- Control unit for real-time synchronization by entering the position/speed of 5-axis

processor into the scanner control board

- World’s first scanner control board for 5-axis signal input

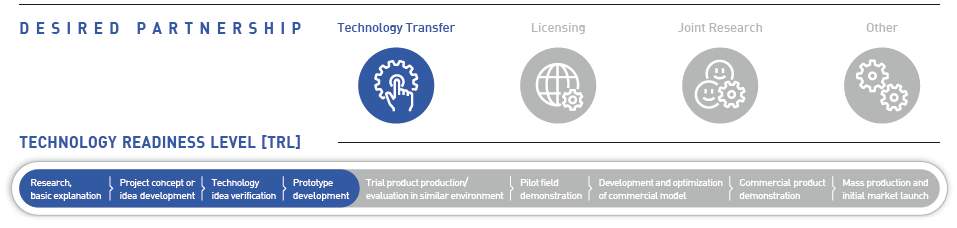

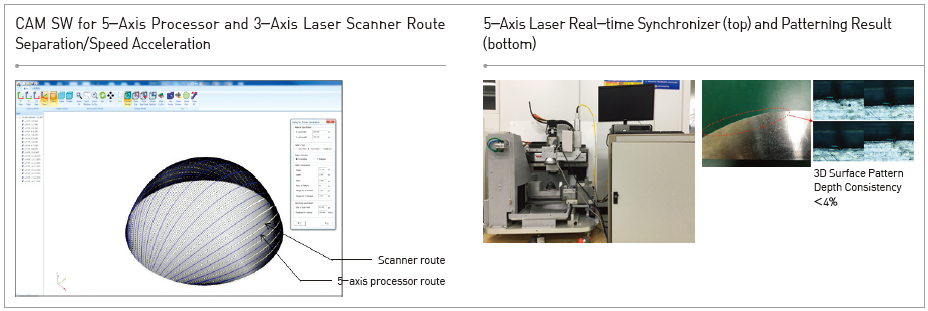

- CAM SW development for separation of heavy weight 5-axis processor transfer

route and high-speed 3-axis laser scanner route/speed acceleration

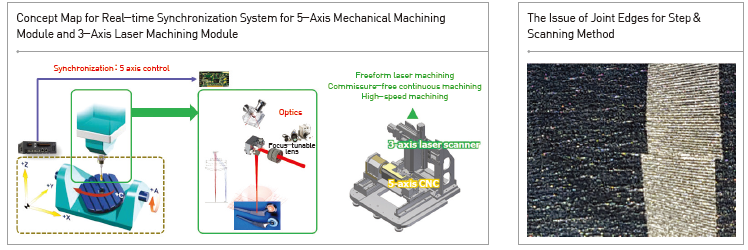

Excellence of Technology

- Real-time synchronization of 5-axis mechanical machining module and 3-axis

laser scanner to surpass the limit of machining area and speed of existing laser.

- With this technology, micropatterning of size 15 μm at the continuous machining speed over

280 mm/s can be performed on a freeform surface of material difficult for processing, Ti.

Current Intellectual Property Right Status

PATENT

- 3D Laser Irradiator and 3D Laser Irradiation Method (KR1769550)

KNOW-HOW

- Scanner control board design technology for 5-axis processor signal input and

real-time correction calculation

- 5-Axis processor and 3-axis laser scanner route and speed acceleration algorithm

|