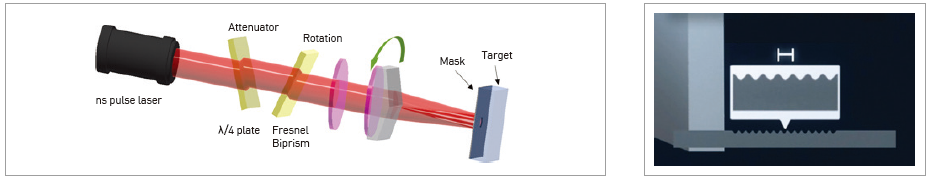

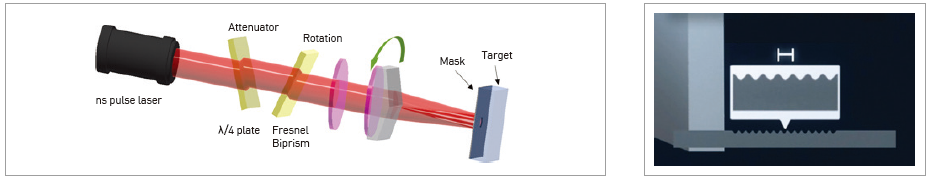

With the micro patterning technology using laser intervention, the

technology enables direct machining on various materials including

metal surface with pulse laser.

Client / Market

- Laser manufacturing equipment

- High-speed micro pattern maker users (e.g. anti-forgery pattern making, pattern

making for catalyst contact area increase for fuel cell or solar cell)

Limitation of Existing Technology

- Existing focus type laser machining has limits regarding diffraction that machining

of small patterns is difficult and the machining time is long due to stage moving, etc.

- Research on laser intervention machining is being conducted to overcome the

problem of above focus type laser machining, however, the research is limited

to continuous wave laser with excellent coherency that it can only be applied to a

photosensitizer.

- Therefore, a high-speed micro patterning technology that can be directly applied for

various materials–metal surface, in particular–is demanded.

Technical Differentiation

- Passible to perform one-shot patterning onto a large area–high-speed patterning

with the speed of 5 n sec

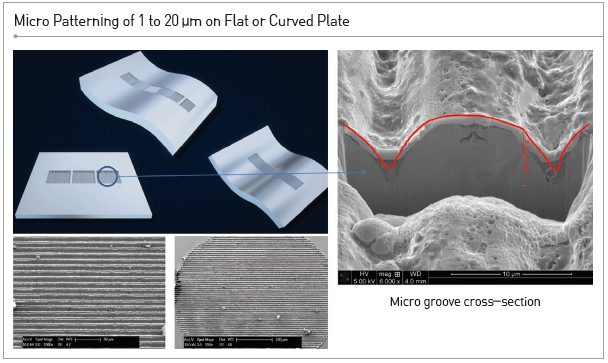

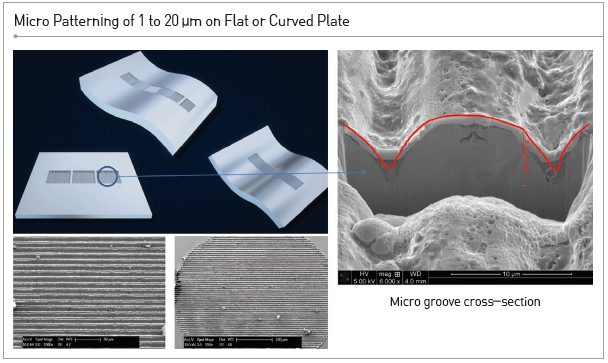

- Possible to create micro patterns with the pattern pitch size between 1 and 20 μm

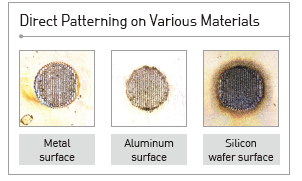

- Possible to perform patterning on all materials where the surface can be polished

including metal surface

Excellence of Technology

- High-speed, large-area patterning technology is expected to shorten the

processing time approximately up to 100 times compared to the existing method.

- Possibility of creating very small line or dot patterns with the pattern pitch size

between 1 and 20 μm has been confirmed.

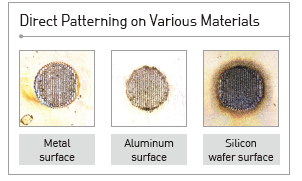

- Pattern making with this technology on various materials including metal,

aluminum, and silicon wafer surface has been verified.

- The optical system can be easily rotated that it can create a line pattern with

different column direction continuously at a high speed.

- Patterns generated with this method can be matched according to the serial

number to be used for anti-forgery.

- A repetitive pattern can be created on a roll or curve by using this technology.

Current Intellectual Property Right Status

PATENT

- Anti-forgery Pattern Generating Device (KR1764835)

- Anti-forgery Pattern Generating Device and Method (KR1688613)

- Anti-forgery Pattern Detection Device (KR1685617)

- Anti-forgery Pattern Detection Device and Method (KR1597754)

- Anti-forgery Pattern Generation Device and Method (KR1528345)

KNOW-HOW

- Synchronization technology for pulse laser, rotary optical system, etc.

- Pattern commissure precision machining technology

|