Laser technology is able to realize electrodes (seed) on a curved or

complex-shaped surface and produce micropatterns stably with a

size under 20 microns using electroless plating

Client / Market

- PCB-based electronic components, automobile industry

- Plastic-based manufacturing industry

Necessity of this Technology

- Recently, the field of printing technology is expanding from 2-dimensional flat

surfaces to 3-dimensional spaces, but a patterning technology on printed-curvedsurfaces

is yet to be realized.

- For existing technologies including photolithography and printed electronics, various

technologies have been developed based on planography, but due to fundamental

technical limitations, it is impossible to print on the complex shaped-surfaces such

as a curve.

- Also, there are issues such as the cost rise from a material waste, the increase

in investment for complex processes, the environmental pollution problem from

chemical processes, and low printing quality due to technical limitations.

- The new technology aims to expand the possible printing area, improve printing

quality, reduce high production cost, and realize an eco-friendly process.

Technical Differentiation

- As the printing area is expanding using a high-performance laser, patterning can be

done on a 3D structures that have curve or other complex shapes such as electronic

clothes. New products can be developed and released.

- With the benefits of laser-high reproducibility and consistency, the highly stable

printing technology can be achieved, resulting in great reduction of the defect rate.

- By minimizing the use of consumable materials such as various solutions and inks

used for chemical processes, the cost of process can be reduced down to 20% in

comparison to the current process cost.

- As the chemical process is minimized, the polluted wastewater can be significantly

reduced and an Eco-friendly technology can be realized.

- As it enables realization of complex patterns, more freedom is given in terms of

designing electronic circuits or components. As a result, it is also favorable for

customized productions and small quantity batch productions.

- Existing technology only allowed plane-to-plane patterning, but with this

technology, the focus of the laser can be adjusted to enable precise patterning on

surface of any kind of shape (even complex surfaces).

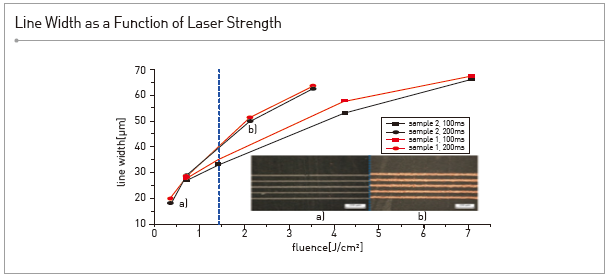

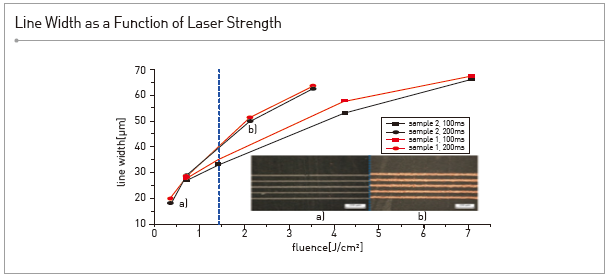

- An existing printed electronics method has serious problems. Uneven line width and

short circuit can be occurred for micropatterning. However, this laser technology

will able to achieve less than 20 μm of micro line width and uniform the width of line

width with high quality.

- The process is based on the direct patterning which is consisted of two stages; seed

generation with laser irradiation and electroless plating. Therefore, the process is

significantly simple and stable.

Excellence of Technology

- This technology is a type of LDS (laser direct structuring) patterning method whose

key factors are the high-performance laser and photo-reactive insulation material.

- High-performance laser should be able to pattern with a consistent line width. The

photo-reactive material should be metallized after react with the laser, and act as a

plating seed (aluminum) for electroplating.

- By exhibiting this technology at ‘Nano Korea 2012’ with the company that

participated in the technology development, the excellence of the technology was

proven.

- The senior researcher has over 20 years of research experience.

Current Intellectual Property Right Status

PATENT

- Manufacturing System of Flexible Printed Circuit Board using Laser and

Manufacturing Method Thereof (KR1377273)

- Flexible Printed Circuit Board Having Conductive Circuit Pattern by Laser Direct

Writing Method and Manufacturing System and Method Thereof (KR0906408) and

Others

|