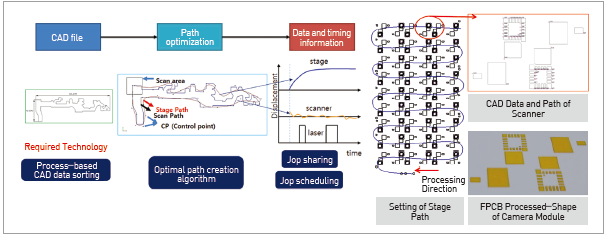

Real-time synchronization of scanner and stage enables continuous

and high-speed processing for a large area, and is also able to

obtain consistent quality for patterning and short process time (20 %

of reduction).

Client / Market

Necessity of this Technology

- To design a system for continuous high-speed/precise laser processing for a large

area, a scanner control board, synchronization algorithm, and on-the-fly system

need to be developed.

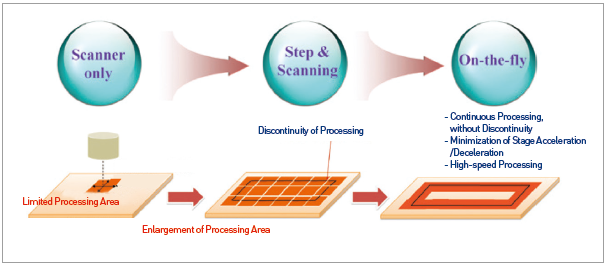

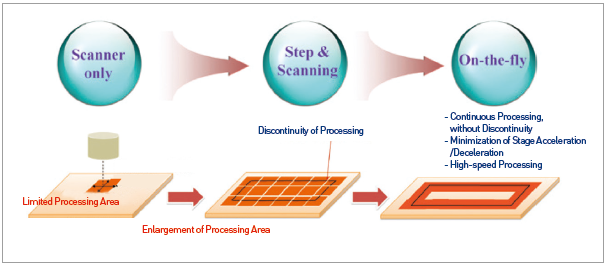

- An existing laser processing using a scanner had a limitation regarding to working

area, and processing on a large area was impossible.

- To overcome this limitation, the step & repeat method using a stage and a scanner

has been used, but the unevenness (discontinuity) at the boundary cannot be

eliminated. Decreasing the degree of precision at the corners due to acceleration

and deceleration of the stage is still a challenge.

- Recently, the industries demand higher degree of precision and larger processing

area in the laser micro processing field

Technical Differentiation

- The laser micro processing has been applied to a limited area, but this technology

enables the continuous processing on a large area.

- For a process that uses laser, the technology enhances the quality uniformity,

resulting in increase of the yield rate. With the continuous processing, the process

time is shortened by approximately 20%.

- Beyond the limitations of the size of laser processing, the scanner and the stage are

synchronized to eliminate an inconsistency that occurred with the scanner process.

With the continuous processing method, the shorten process time and the increase

of degree of precision can be achieved.

Excellence of Technology

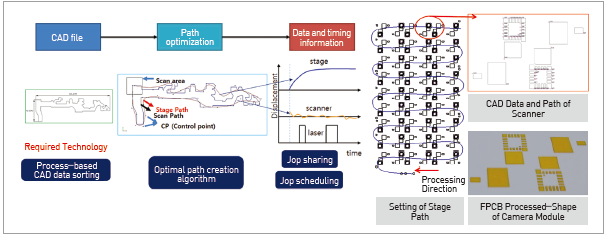

- Technology uses a large area CAD file, and separates the paths for the scanner and

the stage for processing

- The algorithm for drawing the stage and scanner paths and the simulator to realize

it were developed.

- Applied to large cover glass pole film cutting (Technology transfer).

- The technology has been published multiple times including 7 international journals.

- The stage and scanner paths for camera module cover layer cutting were deduced.

- The developed on-the-fly technology is able to achieve high precision and short

process time by the continuous processing.

- Has over 20 years of research experience in laser-related technologies

Current Intellectual Property Right Status

PATENT

- Auto-paging Method Having Scanner-stage Synchronization (KR2012-0058715)

- Synchronization Method for Stage and Scanner (KR2012-0058713)

|