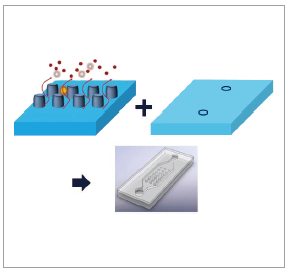

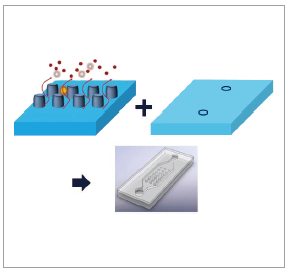

Design and processing technology for packaging, one of the core

technologies for manufacturing of plastic microchannel device

using microchannel with a size ranging from dozen nanos to several

hundred micros, that seals microchannel to prevent leaking of liquid

sample and minimizes deformation of the channel.

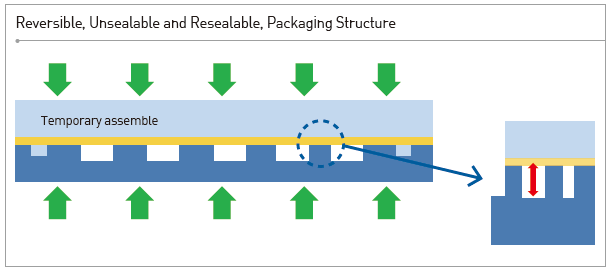

Irreversible packaging technology including plastic plate welding

and adhesion and reversible packaging technology allowing sealing

and unsealing repeatedly.

Client / Market

- Diagnostic device, medical device companies

Necessity of this Technology

- Conventional adhesion or welding packaging technology for plastic material has

difficulty in sealing and maintaining precisely nano/microchannels on the surface

due to heat, pressure, or chemical solvent used during the process that affect the

surface structures and properties.

- Due to the high temperature and chemicals during the packaging process that may

cause damage in various biochemical substance including protein, it can be used

only for very limited applications.

- When irreversible packaging is done with adhesion and welding, unsealing and

resealing is difficult in the middle of using the microchannel device or pre/postprocess

for using the device when it is needed.

- Packaging done with mechanical clamping, the microchannels are hard to be

sealed uniformly, which results in leakage from some of channels frequently.

- It is necessary to apply the optimal packaging design and process technology

that considers the shape and size of the microchannel depending on the purpose,

requirement, and use environment of the microchannel.

Technical Differentiation

- Capable of various irreversible packaging process technologies such as ultrasonic

welding, thermal or adhesive bonding that prevents leaking and minimizes

deformation of the microchannel on a plastic plate.

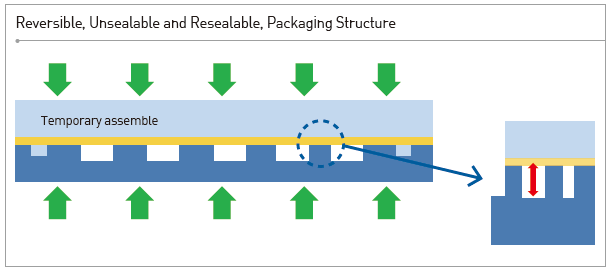

- Capable of reversible packaging process technology, heating-free and chemicalfree,

that can seal the microchannel hermetically and maintain the microchannel

shape and size precisely.

- With the reversible packaging process technology, the device can be unsealed or

resealed repeatedly while the device is in use or in pre- or post-process, which makes

the device be applied to more diversely.

Excellence of Technology

- Reversible packaging technology, prevents negative effect on biochemical

substances like protein and cell due to its heating-free and chemical solvent-free

process, which is a great benefit regarding development of bio devices.

- As a mass producible packaging technology using plastic material, productivity

that is equivalent to that of injection molding can be realized-over 90% yield and

processing time of 1 minute or less.

- Based on this reversible packaging technology, the lead time for a device can be

reduced to from few days to a month, which enables rapid development.

Current Intellectual Property Right Status

PATENT

- Fabrication of Plastic Bio-chip Employing Microchannels (KR1392426, PCT/KR2014

/005141)

- Local Pressurization Typed Microchannel (KR2017-0184209)

- Microchannel with Joints (KR2017-0184201)

- Microchannel (KR2016-0079890)

KNOW-HOW

- Microchannel ultrasonic welding process

- Microchannel film adhesion packaging process

- Thermal and chemical welding for microchannel

|