Method of manufacturing microneedle and needle array that

reduces pain for users and improves solubility in the body

Client / Market

- Beauty and cosmetics, plastic surgery, patch type treatment (vaccine, detox kit, etc.)

Necessity of this Technology

- Microneedle is a technology that has been developed since early 2000s in painreducing

blood gathering and medicine injection methods.

- The initially developed micro needle was mainly made of metal material and

silicone, and it was aimed to reduce the injection pain by simply reducing the size of

the injection needle, but it is difficult to commercialize it because of reliability and

manufacturing complexity.

- In recent years, as the material of the microneedle has been changed into a way to

dissolve in the human body, the microneedle has become a new platform that opens

up various possibilities, ranging from tools to reduce pain to beauty and cosmetics,

plastic surgery, and dry patch vaccines.

- However, there is a limit to the manufacturing technique of making a new type of

micro needle. It is difficult to be technically protected because there is little technical

differentiation between platforms.

Technical Differentiation

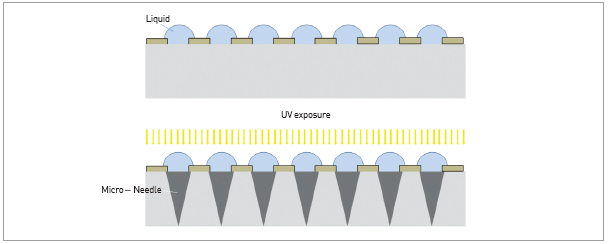

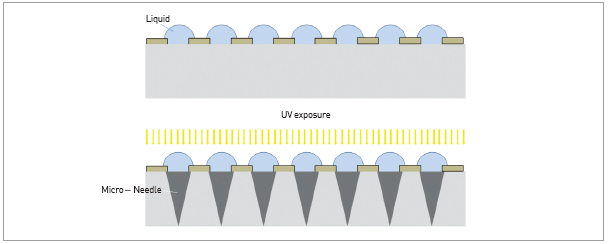

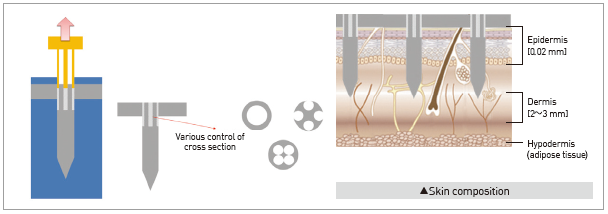

- This technology makes microneedle directly with the stereolithography method or

makes the mold for microneedles.

- In order to avoid the conventional manufacturing method of the micro needle,

the structure of the metal mesh is placed on the light-sensitive polymer. It is a

technique to make the prototype of the micro needle by adjusting the path of light by

collecting light by using liquid droplets formed by surface tension on the mesh after

spraying the liquid on the metal mesh.

- Microneedle can be made directly by adjusting the polymer to be photopolymerized.

Also, the metal mesh itself can be used as a seed to make a mold of

a microneedle by plating, and a metal can be deposited on the circular shape of the

microneedle to be used as a mold for a microneedle after plating. The prepared

molds were filled with functional polymers, and after the curing, the molds were

peeled off to produce micro needles.

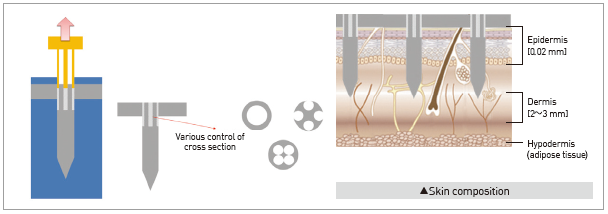

- By adding a design to the microneedle mold, a hollow microneedle can be created

to have desired amount of functional ingredient quickly dissolve in body with the

polymer.

Excellence of Technology

- Original technology that broke away from existing microneedle manufacturing method for creativity issue.

- Mechanical structure-based solubility enhancement technology that preempts demand due to changes in usage of micro needle array

Current Intellectual Property Right Status

PATENT

- Microneedle Mold Manufacturing Method (KR 10-2016-0119783) and 1 other

|