Transfer technology of high-performance electronic devices

made with single crystalline thin film semiconductors (or highperformance

thin films synthesized under high temperature

process) on flexible substrates for continuously mass-producing

flexible electronic devices of high-performance

Client / Market

- Inorganic micro-LED display with high-performance, flexible compound

semiconductor solar cell, flexible thin film battery, wearable and implantable

devices and sensors for human body

Necessity of this Technology

- Development of a flexible electronic device technology with high performance and

great flexibility

- The performance of flexible electronic devices made with organic matters is very

low, and electronic devices made with the semiconductor technology has high

performance but low flexibility. There is a need for a manufacturing technology for a

flexible device with high performance.

- Development of a rollable tablet PC or high-performance display demands

a production technology that can satisfy high performance and flexibility

requirements.

Technical Differentiation

- It is possible to realize and commercialize flexible electronics devices with highperformance using the well-established silicon semiconductor technology. This is

also beneficial to securing yield and reliability of the flexible electronic devices.

- High performance thin film material synthesized under a high temperature can be integrated with a flexible polymeric film.

- It is possible to realize a flexible device with the best performance by transferring an

electronic device with the today’s best specifications on a flexible film.

- The difference of this technology compared to competing technologies (organic

matter-based printing technology) is that it enables flexible electronic device

realization using single crystalline silicon, oxide semiconductor, and III-V compound semiconductor that have outstanding properties compared to any organic semiconductors.

- This technology has higher stability regarding humidity and temperature and higher durability than organic device technology.

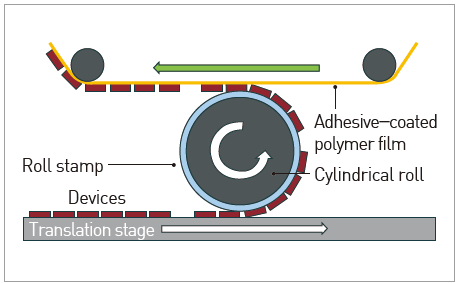

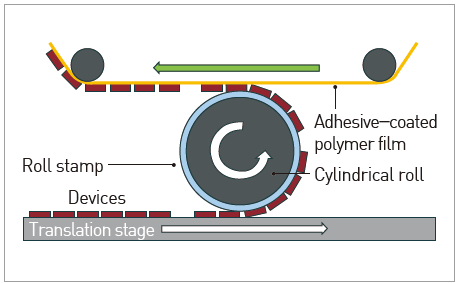

- An improvement is made to overcome the limitations of the flat stamp technologies

by transferring semiconductor thin film on the flexible substrate using a roll-stamp.

Excellence of Technology

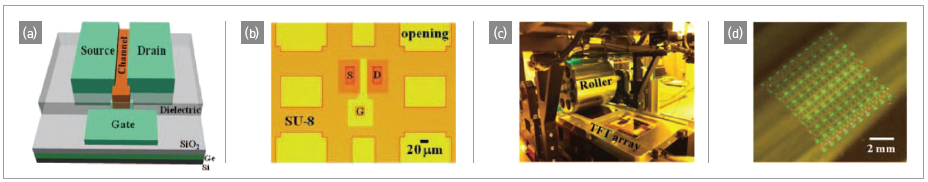

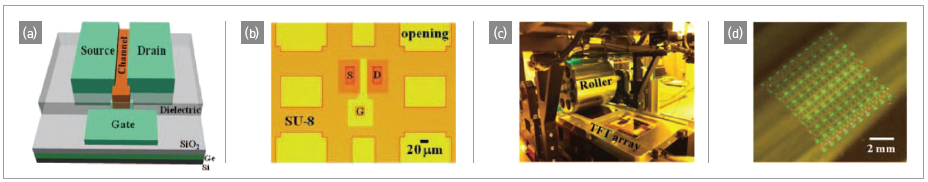

- A high-performance semiconductor device is fabricated in a thin film form on a

substrate wafer. The device is lifted off from the substrate wafer, then transferred

onto a flexible substrate using a roll stamp. This electronic device boasts great

flexibility, and high stretchability depending on the design method.

- Covered by 13 media including Digital Times and SBS on December 27, 2012.

Current Intellectual Property Right Status

PATENT

- Hierarchical Structure and Method for Manufacturing the Same (KR1022016,

US8551353, CN200980129153.3, JP5575766)

- Manufacturing Apparatus for Hierarchical Structure (KR1022017, pct/kr2009/005527,

US13/122.240, CN201310399672.X)

- Stamp for Large Area Transfer and Transfer System Using the Same Stamp (KR0969998)

- Active Removable Chuck (KR0998087, KR1027752, KR1045102)

- Apparatus for Synchronization between Roll Stamp and Translation Stage(KR1227180)

- Flexible Devices with Inorganic Solid Layers and Method for Manufacturing the

Same (KR1093133)

|