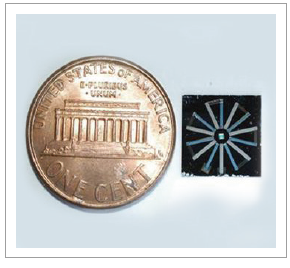

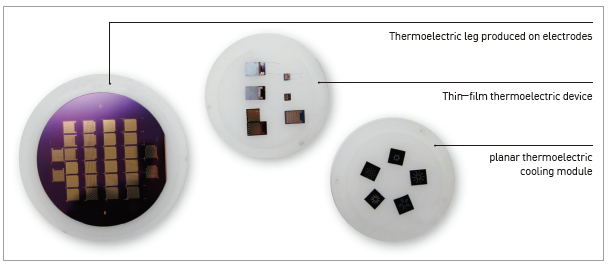

Thin-film thermoelectric module applicable for hot spot cooling and

as micro power supply

Client / Market

- Small portable power supply for WSN (Wireless sensor node), wireless electronics,

portable electronics, MEMS, wearable computer, cardiac pacemaker

Necessity of this Technology

- Micropelt of Germany developed a micro-thermoelectric module using Bi-Te thin

films and Bi-Sb-Te thin films and applied it as a power source of sensor node.

- Laird (formerly Nextreme) of the USA developed a micro thermoelectric module

that can be applied for hot spot cooling.

- GreenTEG of Switzerland developed a micro thermoelectric module and applied for

a heat flux sensor.

- Enhanced strength and reliability of the joint on thermoelectric legs are needed.

Technical Differentiation

- Thermoelectric thin films with power factor of 3.07 mW/K²m for Bi-Te films (N-type)

and 4.41 mW/K²m by Bi-Sb-Te films (P-type) are developed.

- The power output of thermoelectric module is 7.5 mW/cm² when the temperature

difference is 50 degrees.

- It can be used as a wireless sensor power source for monitoring systems used in

environments where battery replacement is difficult such as high temperature, high

pressure, underground, or high above the ground in intelligent plant, smart building,

transport machine, etc..

- It can be applied to hot spot cooling technology where demand for portable hotspot

cooling technology has been increased due to the recent slim and small size

of portable electronic products such as smartphones, tablet PCs, micro-packages,

and LED lighting.

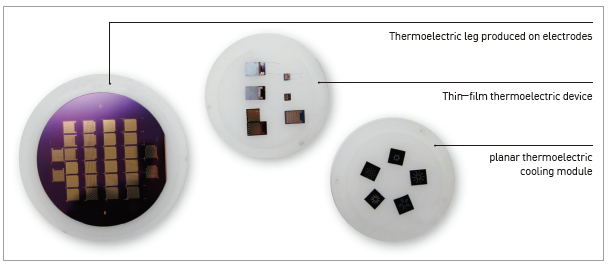

- Secured core elementary technologies

- Thermoelectric module analysis and design technology

- Thermoelectric thin films deposition technology

- Thin-film thermoelectric module process technology

- Performance evaluation technology of thermoelectric thin films and thin-film thermoelectric module

Excellence of Technology

- Finite element analysis technique is used for design to determine the structure and

size of the thermoelectric module.

- Optimal deposition conditions for thermoelectric thin films using co-sputtering and

co-evaporating are secured.

- A measurement technology is developed to assess the performance of developed

thin-film thermoelectric module.

- A bonding process is developed with an exclusive jig designed and produced for

bonding process, and by selecting and evaluating the bonding materials and then

optimizing the bonding conditions.

Current Intellectual Property Right Status

PATENT

- Thermoelectric Energy Conversion Module Having Spring Structure (KR1068647)

- Thin-film Thermoelectric Module Manufacturing Using Transfer Process (KR0984108)

- Method for Manufacturing the Thin-film Thermoelectric Energy Conversion Module (KR1068490)

- Method for Manufacturing a Thin-film Flexible Thermoelectric Module Using Peeling Process (KR0975628)

- LED Package Embedded with Thermoelectric Module (KR1004746, PCT/KR2010/009132)

- LED Package with the Function of Thermoelectric Cooling (KR1064870)

KNOW-HOW

- Analysis-based thermoelectric module design technology

- Thermoelectric thin films optimized deposition technology using vacuum deposition method

- Thermoelectric module manufacturing technology using thermoelectric thin films

- Cooling and power generation performance evaluation technology for thin-film thermoelectric module

|