Heating sheet using printed (carved) pattern that does not require

coating

Client / Market

- Heating device and facility

Necessity of this Technology

- Carbon-coated fiber (carbon fiber) is arranged in grid pattern at irregular distance

on the film.

- Carbon fiber is created by putting regular fiber inside the carbon ink container.

- Here, the distance is inconsistent or controlling distance is difficult.

- The amount of ink coated on the fiber is inconsistent or controlling thickness is

difficult.

- The amount of power generation differs by distance and amount of ink coated.

- Degradation occurs at a lump, and due to different amount of heat generated, the

film peels off.

- Resistance is great where the line is thin, and it causes short circuit.

- Difficult to generate electricity and heat of the same size.

Technical Differentiation

- Easy to laminate the protection film.

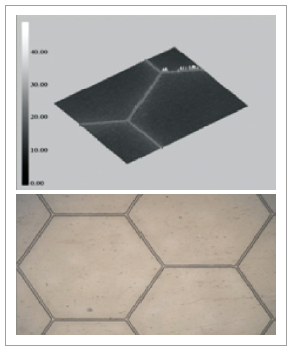

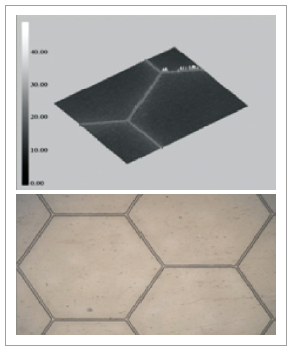

- Pattern distance is made consistence through printing (carving).

- Possible to adjust the size of the quantity of electricity and heat as distance can be

adjusted variously.

- Printed (carved) pattern allows for pattern making at a consistent thickness in the

same process.

- With the option of various thickness adjustment, the size of electricity quantity and

heat quantity can be adjusted.

- Constant electricity and heat can be generated, and degradation or short circuit

does not occur.

- With printing (carving) method, carbon ink is arranged in grid pattern at consistent

distance on the film.

- Different from existing process (Putting inside the ink container, carbon coating of

fiber is not needed.)

Excellence of Technology

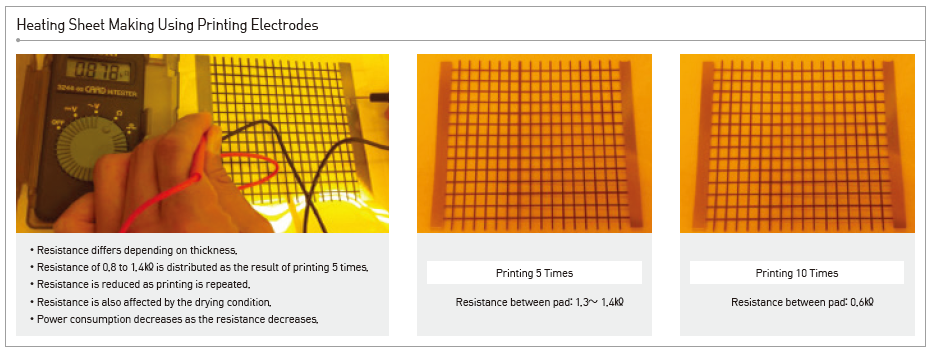

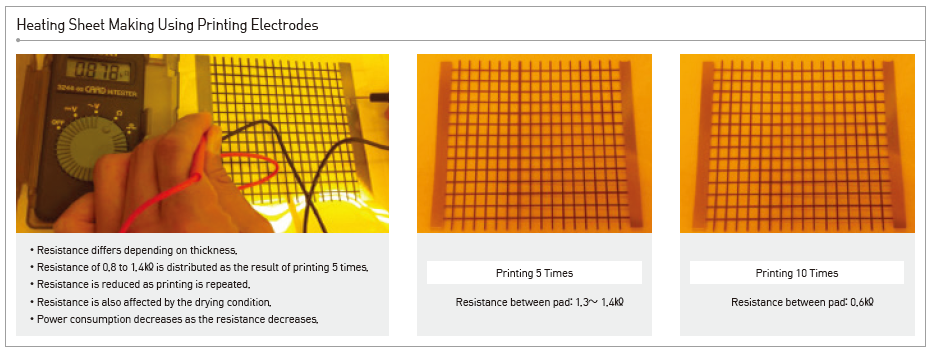

- Place the conductive printing electrodes between the thin flexible film and the

protection film, and connect outsider power to the power plug connected to the

printing electrodes to generate heat at the electrodes.

Current Intellectual Property Right Status

PATENT

- Heating Sheet Using Printing Electrodes (KR1480160)

- Electric Oscillation Generator Using Printing Electrodes (KR1450212)

|