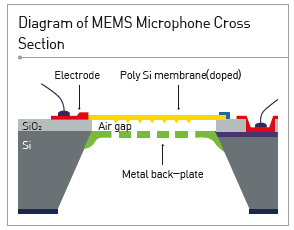

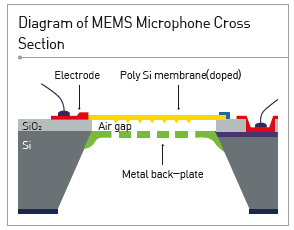

MEMS microphone is realized with the vibrating plate that responses to the sound and the back plate on the opposite side used as stationary electrode, and the back plate used for this invention is made thick and solid using electroplating. The process and the cost is expected to be reduced significantly with this technology.

Client / Market

- Microphone manufacturer, mobile device manufacturer, hearing aid manufacturer, entertainment device company, noise diagnostic instrument company

Necessity of this Technology

- Adoption of a cheap, simple process is needed by using electroplating for thick and solid back plate.

- Generally, for existing MEMS microphone, the electrode in the thin back plate is made with surface micromachining, which causes fundamental sensitivity degradation.

- Also, air hole etching process for the back plate adds cost.

- Miniature microphone applied for mobile phones and devices is replaced from ECM (electret condenser microphone) to MEMS microphone, and in 2016, the market is expected to achieve 2 billion products sales and 1.5 billion dollars in size.

- Currently, the domestic market depends completely on imported miniature MEMS microphones. With the explosive increase in smart phones, a steep increase in demand for MEMS microphone is expected. It is necessary to develop a cheap, highperformance product with domestic technology.

Technical Differentiation

- When the stationary back plate is processed using electroplating, the sensitivity of microphone is expected to be enhanced while the production stage and cost is expected to be reduced.

- It induces domestic technology development and production in the miniature microphone that entirely depends on import at the moment.

- By using electroplating for a thick back plate to create a MEMS microphone with a solid back plate, sensitivity enhancement compared to existing microphone is realized.

- By applying electroplating for the back plate no in the surface micromachining but bulk micromachining, the number of processes will be reduced compared to existing process, which means lower cost.

Excellence of Technology

- It is a miniature MEMS device composed of the vibrating plate (moving electrode) facing the back plate (stationary electrode), and when sound is input in the variable condensing state while voltage is applied for both ends, the distance from the electrode of the back plate changes as the vibration plate starts to vibrate.

- Following this, the capacitance change is detected for the output.

- For a general MEMS microphone, surface micromachining is applied to have a relatively thin stationary back plate, but the thick, solid back plate proposed in this research is expected to have a rapid increase in sensitivity. Also, by applying body etching and metal-plating in the back plate manufacturing process, the entire process and the cost are reduced.

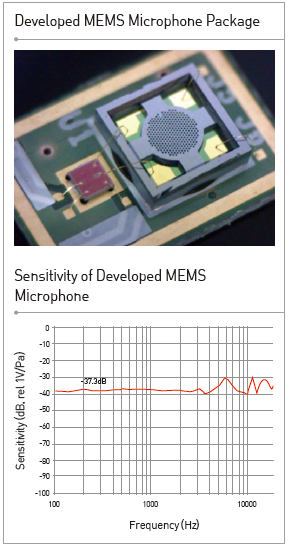

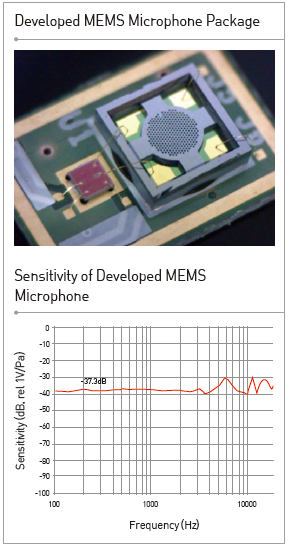

- MEMS microphone applying the back plate in the image above combined with developed CMOS ASIC chip showed outstanding sensitivity of approximately 37.3 dB.

Current Intellectual Property Right Status

PATENT

- MEMS Microphone Package and Manufacturing Method of the Same (KR1118624)

- MEMS Microphone and Manufacturing Method (KR1118627)

- MEMS Microphone Based on Graphene Membrane and Fabrication Method Thereof (KR1058475, PCT/KR2011/003584)

- Ultra-small-size Microphone Based Hearing Aid Apparatus (KR1031113)

- 1-Chip-type MEMS Microphone and the Method for Making the 1-Chip-Type MEMS Microphone (KR1472297)

- MEMS Microphone with Dual-backplate and Method the Same (KR1379680, PCT/ KR2012/010259)

- Sound Measuring Apparatus Having Flexible Substrate Using MEMS Microphone and Method for Making the Apparatus (KR1346583)

- MEMS Microphone (KR1462375)

- Making Method for 1-chip-type MEMS Microphone and the 1-chip-type MEMS Microphone by the Method (KR1407914)

|