3D printing system (3D printer) is a device that uses various methods to stack materials layer by layer. It can produce 3D products in various forms, and it only uses material that is needed to create the products-no more, no less. Depending on the material used, it can be used for different fields.

3D bio-printing system (3D bio-printer) is a device that uses biomaterial or cell to make 3D tissues and organs.

In the aging society resulting from advance in modern medicine and improved standard of living, the demand for artificial organ is rapidly increasing, but the supply is far from enough. With the 3D bioprinting technology, such issues are expected to be resolved.

Client / Market

- Medical and healthcare industry-hospital, doctor

- Artificial tissue/organ market

Necessity of this Technology

- Research on artificial organ is being conducted actively in the tissue engineering field. Tissue engineering is the use of a combination of cells, engineering and materials methods, and suitable biochemical and physicochemical factors to improve or replace biological tissues.

- Stem cell has been used to solve the lack of tissue and organ problems, but control for the stem cell differentiation process is difficult.

- 3D bio-printing has the potential to overcome the drawbacks by direct 3D printing the biomaterials and cells to produce the artificial tissue and organs.

Technical Differentiation

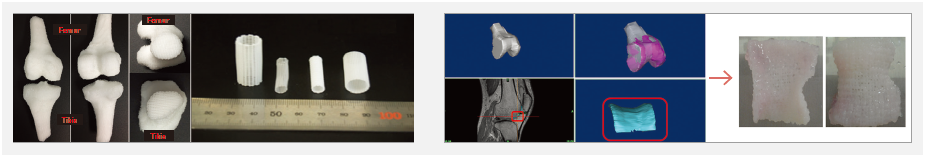

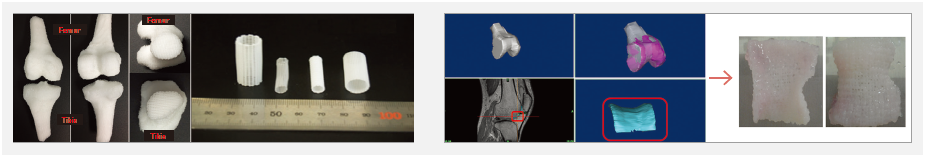

- Scaffold for artificial tissue/organ can be made based on a medial image (CT, MRI, etc.).

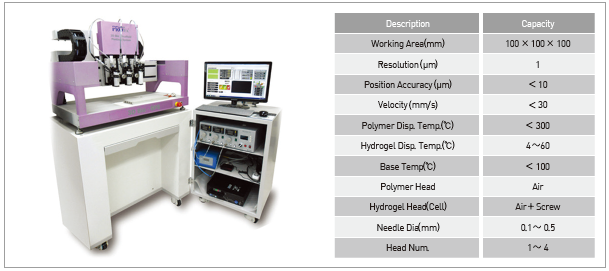

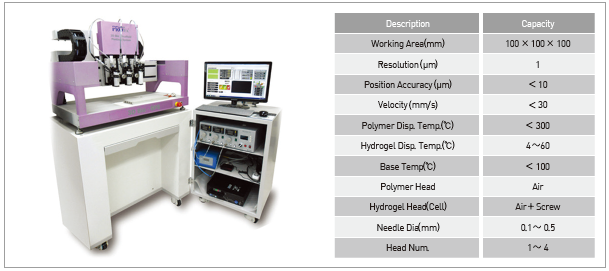

- Can print with various biomaterials (biodegradable/biocompatible polymers, hydrogels, etc.).

- Can print cells in three dimensions

- Can print various materials simultaneously using multi-head system

- Can print tube shape scaffold with a minimum diameter of 1 mm

- Can print strand in the scaffold with a dimeter of 100 μm

Excellence of Technology

- Can make a scaffold for artificial tissue (bone, cartilage, etc.) using biodegradable/biocompatible polymers in various shapes based on the medical image (CT, MRI, etc.)

- Can make human tissue by directly printing cells based on the medical image (skin, cornea, etc.)

Current Intellectual Property Right Status

PATENT

- A Device for Manufacturing Regeneration of a Three-Dimensional Tissue (Patent registered, 0916633)

- A System for Manufacturing Regeneration of a Three-Dimensional Tissue (Patent registered, 0932960)

- Cell Plotting Apparatus for Three-Dimensional Cell Culturing Support (Patent registered, 1110797)

- Air Jet Scaffold Manufacturing Device and Manufacturing Method for Using the Same (Patent registered, 1566810)

- Fabrication Method of Arbitrary Shape Scaffold and the Scaffold Made by the Method (Patent registered, 1515948)

- Multi-type Scaffold Manufacturing Device and Scaffold Using the Same (Patent registered, 1437850)

- Cell Culturing Scaffold Manufacturing Apparatus and Cell Culturing Scaffold Manufactured Using the Same (Patent registered, 1332789)

- Cell Culturing Support Manufacturing Apparatus and Cell Culturing Support Using the Same (Patent registered, 1320932)

- Tube Shape Scaffold Manufacturing Device and Scaffold Made by the Device (Patent registered, 1478155)

- Tube Shape Scaffold Manufacturing Device and Scaffold Made by the Device (Patent registered, 9730817)

- Multi Nozzle Type Scaffold Manufacturing Device and Method for Using the Same (Patent registered, 1538024) and others

KNOW-HOW

- Printing condition (materials, temperature, speed, pressure, etc.)

|