Gravure offset printing system to be used in printed electronics by

securing the precise overlay accuracy at 10 μm level

Client / Market

- Manufacturer of printing system for printed electronics

Necessity of this Technology

- New machine structure for the μm-level alignment technology at is needed

- Precision machine technology to reduce run-out error of printing cylinder is needed

- Machine control technology using microscopic vision is needed

- Equipment and process for rapid drying is needed for high-speed manufacturing

- Conventional printing method can be applied for the media printing, with the overlay

accuracy of only 100 to 150 μm.

- Conventional rotary printing technology has a low overlay accuracy and thus cannot

be used for the multi-layer structure for an electronic device. Previously developed

printers for printed electronics are mostly used for single layer printing.

Technical Differentiation

- Can dominate the rotary printer market for printed electronics that require multilayer

structure

- Provides overlay accuracy within 10 μm by capturing and manipulating overlay error

based on the measuring of fine register marks using microscopic vision system

- Provides a printing technology that secured productivity by inline printing multilayered

electronic devices

- Inline overlay printing of printed electronics with multi-layered structure

- Multi-layered micro electronic circuit patterns with micro line width, such as capacitor and

transistor, can be mass produced with the roll-to-roll inline overlay printing method.

- The unique transfer method where the micro-patterns from the gravure cylinder

are transferred to the printing cylinder with soft silicon rubber and then transferred

100% as-is on the printing subject with low contact pressure shows the benefits of

3D ink layer formation.

- Printed fine register marks are captured with the microscopic camera vision

system, and the position error are adjusted and corrected continuously by operating

the motor to realize the overlay level within 10 μm-level.

- Analog printing techniques for printed electronic devices such as gravure have high

productivity but cannot form micro-patterns. The digital printing techniques like

inkjet can create micro-patterns greater than 10 μm but have low productivity.

- However, this roll-to-roll rotary printer offers both benefits-micro-pattern

formation and high productivity.

- In addition, the limit of existing overlay printing technique, overlay accuracy of

100 to 150 μm, was enhanced to achieve a precision at the 10 μm level, and the 3D

overlapping printing, which was previously unrealizable with existing rotary printing,

is made possible.

Excellence of Technology

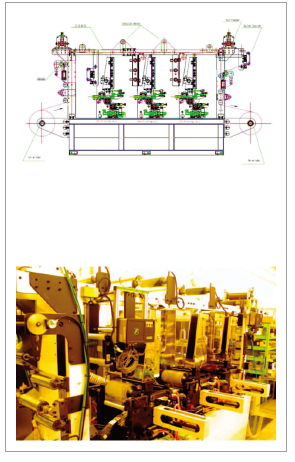

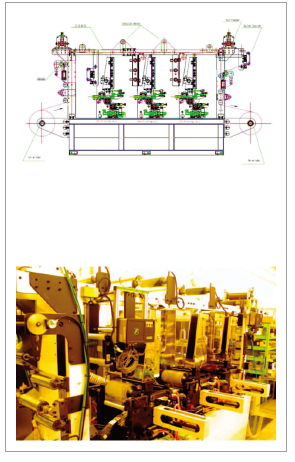

- The size of the gravure cylinder installed in the roll-to-roll inline rotary printer, with

3 gravure offset printing units, is 150 mm in diameter (Φ) and 260 mm in width.

- The result of producing an electronic circuit through the 3-layer printing with paste

Ag ink showed a satisfactory conductivity of 200 mΩ/m.

Current Intellectual Property Right Status

PATENT

- Electronic Element Production Device Using Roll-to-Roll Rotary Printing Method (KR1014363)

- Line Pressure Control Device for Roll-to-Roll Rotary Printing System (KR0911214)

- Electronic Element Production Device Using Roll-to-Roll Rotary Printing Method

and the Manufacturing Device (KR0634327 EP06112095.2)

- Blanket Cylinder for Offset Printing (KR2007-0101925)

- Gravure Printing Cylinder Enabling Ink Cleaning Without Vibration (KR2009-0055371)

- Printing Unit for Offset Printer Composed of Non-vibrating Rotating Cylinder

(KR2009-00553713)

- Electronic Element Production Method and Production Device Using Roll-to-Roll

Rotary Printing Method (PCT/KR2008/006168)

- Arraying Method for Printed Electronic Layer by Different Register Marks (KR1071630)

- Electronic Element Production for Rotary Press and Method (KR1096529)

- Lateral Registration Drive Device of Gravure Offset Plate Cylinder for Printed

Electronics (KR2013-0021549)

- Overlapping Printing Method for Rotary Printing of Printed Electronics (KR1300192US13

/627523)

- Overlapping Printing Apparatus and Method for Rotary Printing of Printed Electronics

(KR1288135)

- True Rolling for Electronic Element Production Device (KR1152775)

- Register Marking Method and Its Device for Printed Electronics on Roll-to-Roll

Gravure Offset Printing Process (KR2013-0094982)

- True Rolling by Page Length in Gravure-Offset Printing Unit (KR1393537)

- Electronic Element Production Device Using Roll-to-Roll Rotary Printing Method

and the Manufacturing Device (KR0634327)

|