Technology related to functional surface which controls the reflectivity of the basic material by modulating the height of the nanostructures on the substrate surface

Technology to control the reflectivity of each wavelength by the nanostructures on the surface without a chemical coating layer

Client / Market

- All surfaces that need anti-reflective coating and all hydrophobic surfaces such as glass window, mirror, glasses, optical components, display cover glass, and solar cell cover glass

Necessity of this Technology

- Creating a transparent and excellent water repellency surfaces with self-cleaning effect where impurities do not get stained or are removed easily

- Many attempts were made to form a nanostructure on a transparent surface to realize enhanced transparency and super water repellency, but the most frequently used method was the nanostructuring transfer method of transparent macromolecules, which had drawbacks such as difficulty to form nanostructures on the surface densely or being easily broken from contact.

- For a glass installed outdoor, a significant amount of money is spent to remove dust piled on the surface, therefore, a glass that is easy to clean with small amount of water (rain) and has high light transmittance.

Technical Differentiation

- As it uses the self-assembly nanoparticle layer as a mask for etching, the cost for processing is cheap, and the process time is relatively short.

- The glass surface is etched to form nanostructures, the structures are relatively mechanically robust and the properties are less affected by external environment.

Excellence of Technology

- A self-assembly nanoparticle layer is used as a mask, and then the plasma etching process is followed to make nanostructures on the transparent glass substrate.

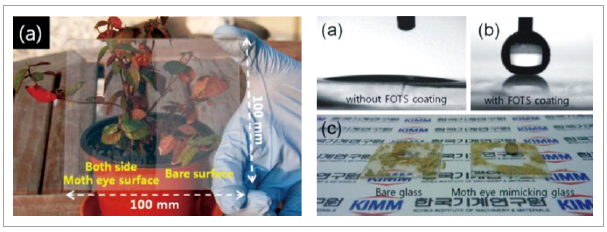

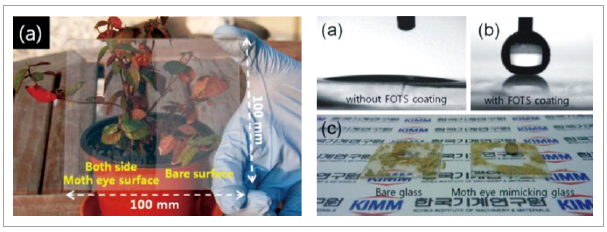

- This nanostructured glass plate has 2 to 3% higher transmittance compared to a glass without nanostructures as shown in the graph on the left below.

- The nanostructured glass after the plasma process shows ultra-hydrophilic properties as shown in Figure (a) on the right, and after the low surface energy chemical coating, ultra-water repellency with the water contact angle over 150˚ is realized as shown in Figure (b).

- The senior researcher for this technology has over 10 years of research experience.

Current Intellectual Property Right Status

PATENT

- Fabrication Method for Functional Surface (KR1340845)

- Fabrication Method for Functional Surface (KR1340874)

- Fabrication Method for Functional Surface (KR1103264 JP5220066 US8728571)

- Method for Manufacturing Superhydrophobic Surface and Super Water-Repellent Face Product Manufactured by the Same (KR1165606)

- Method for Manufacturing Superhydrophobic Surface (KR0854486, US8, 216, 483, CNZL 200780052518.8, EP07851416.3)

- Manufacturing Method for Anti-reflective Surface and Super Water-repellent Surface (KR1014277)

- Patterning Method for Nano-Structure (KR1168250)

- Biochip and Method of Producing the Same (KR1337504)

|