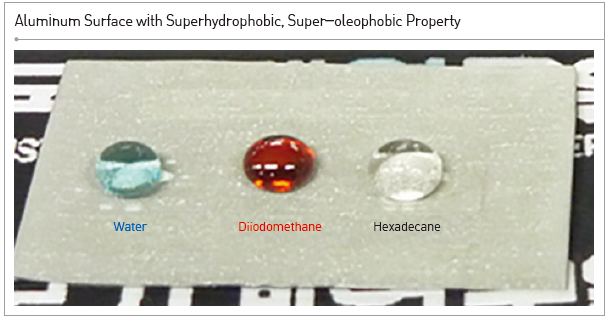

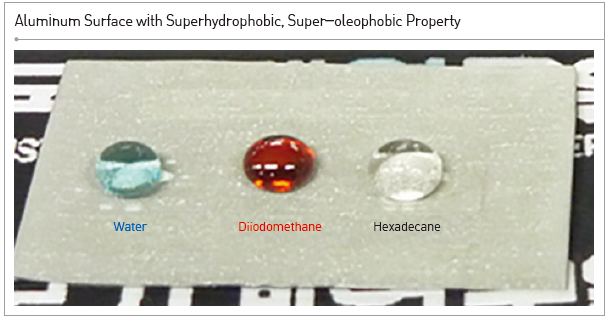

Manufacturing for high contact angle using surface nanostructure and chemical coating

Manufacturing for easily cleaning surface with less contamination

Client / Market

- All surfaces that needs to be maintained clean, all hydrophobic surfaces

- Home appliances: Cooling equipment such as frying pan, interior material of bathroom wall, glass material for window, kitchen furniture surface

- Industrial products: External material for ship, car, aircraft surface, nuclear energy fuel rod surface, spacecraft glass surface, heat exchanger, insulator, solar cell protection glass, external material for construction

Necessity of this Technology

- Superhydrophobic property that reduces the surface’s contact with water results from the chemical property of low surface energy and the surface structure with less contact. This technology can be applied for home/living products as well as different industries that a lot of studies are being conducted for it.

- Most of the existing technologies use chemical coating based on fluoride compounds that have durability and long-term safety issues for using various environments (including high temperature and pressure).

Technical Differentiation

- High-durability, eco-friendly, superhydrophobic surface treatment technology that can be used under 500℃

- Customized coating is possible for each end-item and applications with various temperature conditions

- One step process for surface nanostructure formation and chemical coating to reduce the manufacturing time and cost

Excellence of Technology

- High heat-resistance superhydrophobic coating technology with superhydrophobic property under 500℃ or higher

- High wear-resistance coating that tolerates scratches and shocks

Current Intellectual Property Right Status

PATENT

- Gas Sensor having Nano-Wire Network Structure and Method for Manufacturing the Gas Sensor (KR2017-0048405)

- Water Repellent heat Sink and Method for Manufacturing Thereof (KR1136391)

- Method for Making Superhydrophobic Metal Surface (KR1424995)

- Hydrophobic De-icing Tip for LPLi Injector (KR2012-0106459)

KNOW-HOW

- Equipped with process technology that can be applied for various materials

- Possible to generate a customized contact angle in wide range

- Conducted various experiments on water condensation and dew condensation

|