Stirling cryocooler is a machine that creates cold environment

and composed of a set of a compressor, an expander and heat

exchangers.

The Stirling cryocooler generally adopts Helium as a working gas

and it can readily reach the temperature below -200℃.

The technology can be utilized for various temperature ranges (from

under -200℃ to -15℃) and cooling capacities (from under W-class

to kW-class).

Client / Market

- Stirling cryocooler can be applied in various fields depending on operating

temperature and required cooling capacity.

- Infrared (IR) thermal imaging sensor cooling device for military and space

- Cooling systems for superconducting power applications (superconducting cable,

superconducting fault current limiter; SFCL, superconducting transformer)

- Small-scale LNG liquefaction/re-liquefaction (–160℃) system

- Ultra-low temperature refrigerator for bio storage

- Low GWP (global warming potential) refrigerant-applied refrigeration/freezing system

Necessity of this Technology

- Stirling cryocooler has the highest efficiency among low-power cryocoolers.

- The cryocooler accompanied with an oil-free linear compressor is completely free from

a clogging problem so that it possesses high mechanical work conversion efficiency

with no valve loss and promises long operation life. There is no risk of breakdown due to

impurities hardening under an extremely low temperature below –60℃.

- The system can be compact as all components-compressor, expander and heat

exchangers-are a single unit.

Technical Differentiation

- Stirling cryocooler technologies on various types

- By compressor : rotary compressor, linear compressor

- By piston and displacer arrangement : alpha-type, beta-type, gamma-type

- Our work group has remarkably worked and secured toward on a ‘free piston Stirling

cooler (FPSC)’ accompanied by a linear compressor.

- Cooler design that considers electro-magnetic, thermo-hydraulic and dynamic

characteristics for the entire cooler development process

- Ease of temperature and capacity controlling under an extensive temperature range

with high turn-down ratio

- This technology utilizes Helium as a refrigerant with GWP (global warming potential)

of zero so that it agrees to the Paris Agreement.

Excellence of Technology

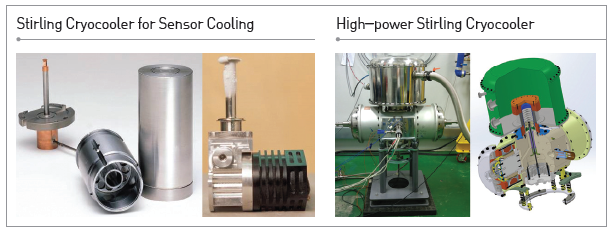

- Development of Stirling cryocooler for infrared (IR) thermal imaging sensor cooling

- Rotary compressor and linear compressor adopted Stirling cryocooler with cooling

capacity of 0.4~1.0 W (at –200℃)Development of Stirling cooler

- Development of day-night observation facilities for military use and tank panoramic

sight

- Approval for military

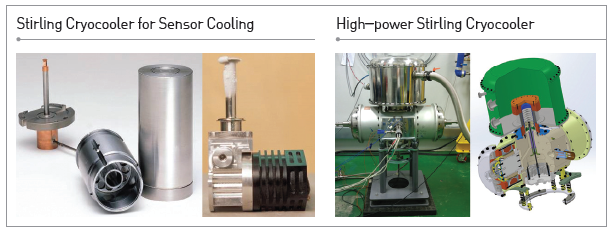

- Development of high-power Stirling cryocooler for superconducting power

application cooling system

- kW-class linear compressor driven Stirling cryocooler for liquid nitrogen cooling

- Ease of miniaturization and maintenance compared to conventional cryocooler driven

with crank-cam reciprocating compressor lubrication involved

- Performance test of 2 kW (at -200℃) verified through the liquid nitrogen (LN2) circulation test

CURRENT INTELLECTUAL PROPERTY RIGHT STATUS

KNOW-HOW

- Linear motor design and optimization technology for Stirling cryocooler

- Compressor and low-temperature expansion device optimization technology

- Stirling cryocooler dynamics and thermal design, layout creation and assembly

technology

- Stirling cryocooler operation control and performance analysis technology

- Development technologies for various operating temperatures and cooling capacities

|