Cooling technology to create and maintain thermal environment

below extremely low temperature (120 K, -153℃)

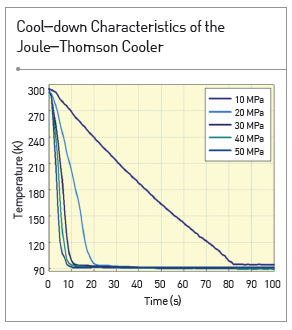

Technology using expansion of gas compressed with several

hundred atmospheric pressure to cool down to an extremely low

temperature within a few seconds

Client / Market

- Rapid cooling of infrared detector, small analytical instrument, cryosurgery, gas liquefaction

Necessity of this Technology

- Cryogenic cooling is crucial for a cooling type detector to achieve high resolution

and clear image.

- For cryosurgery using extremely low temperature require safe and temperaturecontrolled

cooling technology.

- Joule-Thomson cooling technology is a cooling technology that is smaller than

other cryocoolers like Stirling cooler, pulse tube cooler, and GM cooler, can be

operated under lower vibration level and enables rapid cooling.

Technical Differentiation

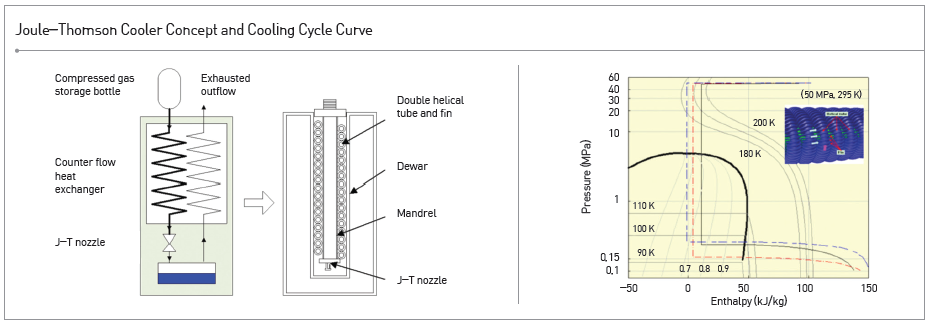

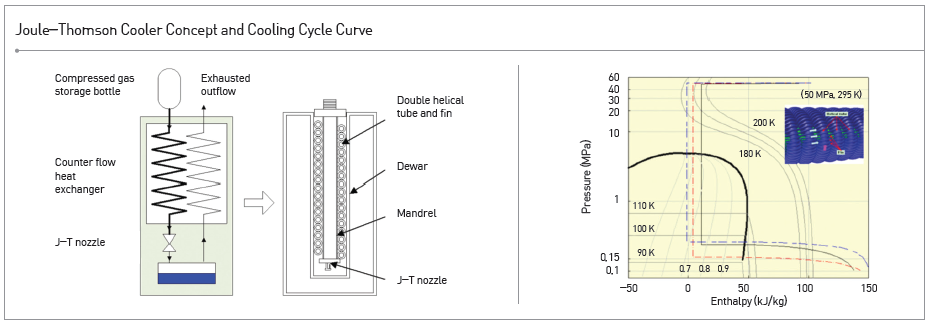

- Joule-Thomson cooling technology uses the cooling effect (Joule-Thomson effect)

that occurs through sudden expansion of high-pressure gas that passes through

a fine nozzle and amplifies the cooling effect through the high-efficiency heat

exchanger to generate cryogen for cooling.

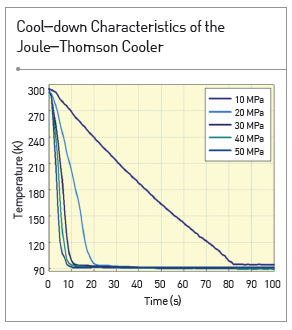

- In cooling of infrared detector, the Stirling or pulse tube cryocooler requires a

few minute, but Joule-Thomson cooler uses a high flow rate of high pressure

compressed gas to cool down to a cryogenic temperature in a few seconds. Its

structure is relatively simpler and is easy to be miniaturized.

- A series of development process is needed for development of Joule-Thomson

cooler including cooling cycle design, design and production technologies for

components like heat exchanger, nozzle and flow control apparatus, and cooling

function performance test.

- To secure sufficient cooling and long operating time while achieving rapid cooling,

it is necessary to obtain optimal design technologies for small/high-efficiency heat

exchanger, nozzle and flow control apparatus.

- For performance assessment of Joule-Thomson cooler, vacuum and cryogenic

environment need to be established, and the thermal/structure design and

operation technology of performance evaluation apparatus needs to be secured.

Excellence of Technology

- Equipped with technology for the entire development process for Joule-Thomson

cooler–cooling cycle design, design of components (heat exchanger, nozzle, flow

control apparatus), and cooling performance assessment (In-house design program

for Joule-Thomson cooler design/cycle analysis/heat exchange and nozzle design

program)

- Performance analysis technologies for Joule-Thomson cooler in steady and

transient state

- Thermodynamic cycle analysis technologies for single (nitrogen, argon) and mixed

refrigerant

- Completed verification of the technology through rapid cooling Joule-Thomson

cooler development and performance test

CURRENT INTELLECTUAL PROPERTY RIGHT STATUS

PATENT

- Joule-Thomson Cooler Design (Program JTGUI: Registration No. 2011-01-123-

005467, JTDESIGN2 : Registration No. 2011-01-123-005453)

- Joule-Thomson Cooler Cycle Analysis (Program JTR-CD (Joule Thomson

Refrigerator-Cool Down) : Registration No. 08-01-121- 003011, JTC2ST : Registration

No. 2010-01-121-004322)

- Nozzle, Flow Control Apparatus Design (Program NzFlow : Registration No. 2009-

01-121-005649, TdBellows : Registration No. 2011-01-123-004743)

- Joule-Thomson Cooler Thermal Load Analysis (Program ColdFinger : Registration

No. 2009-01-121-001780)

KNOW-HOW

- Joule-Thomson cooler’s cooling performance assessment technology

|