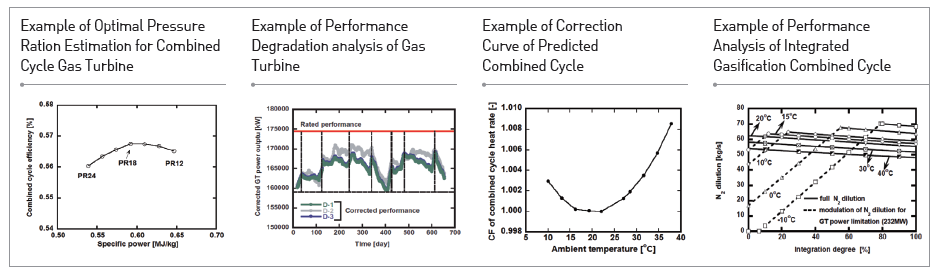

Performance analysis technology of gas turbine combined cycle

system composed of various components such as gas turbine (GT),

heat recovery system generator (HRSG), and steam turbine (ST)

using a physics-based model

Application fields of the performance analysis technology using

a physics-based model : 1) performance design, performance

acceptance test, and performance diagnosis of conventional power

generation system, 2) Development of advanced power generation

system such as integrated gasification combined cycle, gas turbinefuel

cell hybrid system

Client / Market

- Gas turbine manufacturers

- Engineering companies for energy systems

- Electric power companies with gas turbine combined cycle

Necessity of this Technology

- Combined cycle gas turbine performance design aspect: In the performance design

of gas turbine for combined cycle, gas turbine performance design considered the

performance characteristics of the bottoming cycle is required to maximize the

efficiency of the combined cycle.

- Gas turbine combined cycle power plant performance acceptance test aspect: In the

performance acceptance test of gas turbine combined cycle power plant, correction

curves of the combined cycle power plant derived by combining the design

specifications of components is required, and the curves are utilized to examines

whether the completed gas turbine combined cycle power plant is able to fulfill the

performance in the contract.

- Gas turbine combined cycle power plant performance diagnosis aspect: In the

performance diagnosis of gas turbine combined cycle power plant, the analysis for

the degree of degradation and the cause of deterioration were required to predict

the appropriate maintenance schedule because the performance of gas turbine

degrade with increase in operation time.

Technical Differentiation

- Performance design of gas turbine for combined cycle

- Estimation of realistic gas turbine performance specifications by utilizing the regression analysis

model obtained through analyzing data from existing gas turbine, and physics-based mode

l- Prediction of design performance specifications of gas turbine for combined cycle by

simulation of gas turbine system with bottoming cycle using the physics-based model

- Performance acceptance test of correction curve for gas turbine combined cycle

power plant

- Accuracy improvement of correction curves of combined cycle by utilizing the modelbased

simulation of overall combined cycle power plant as well as combination

correction curves of each component provide by manufacturer’s

- Prediction of the correction curves of combined cycle power plant with inlet chiller and

duct firing

- Diagnosis of gas turbine combined cycle power plant performance

- More accurate quantitative analysis of performance degradation using physics-based

model than that of using data analysis

Excellence of Technology

Current Intellectual Property Right Status

KNOW-HOW

- Performance design of gas turbine for combined cycle power plant

- The prediction of correction curves of combined cycle power plant

- The performance diagnosis of gas turbine

- Analysis of advance gas turbine-based energy system

|