Compressors and blowers are key elements that generate gas flow

or pressure rise in gas turbine, industrial process and household

applications.

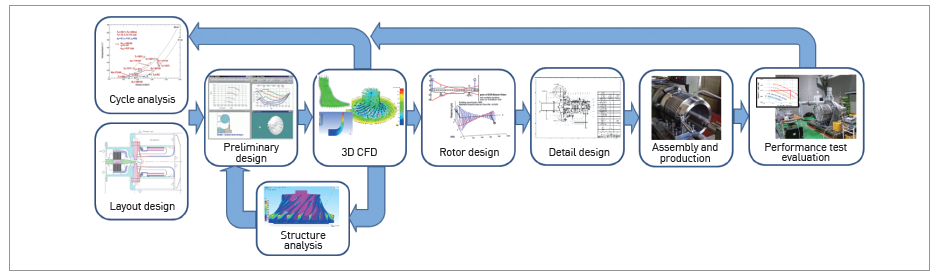

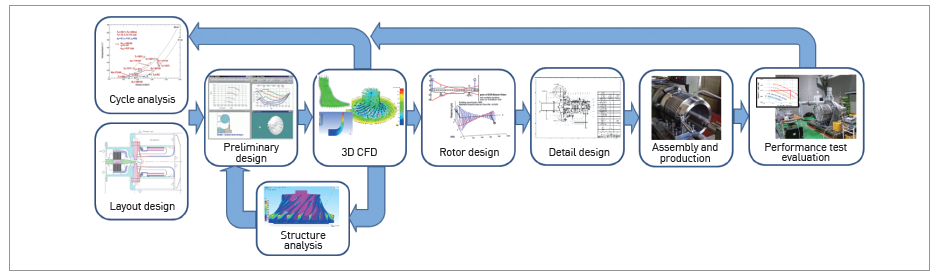

Compressor design (aerodynamic, structure, cooling, vibration,

mapping) to satisfy the target performance under various operating

conditions and testing technology

Compressor performance assurance and performance estimation

in design and off-design conditions

Client / Market

- Gas turbine manufacturer/user company

- Industrial process or general use compressor and blower manufacturer/user

company

Necessity of this Technology

- Multidisciplinary technology is required (design: aerodynamics, structure,

vibration, heat transfer/manufacture: material, tolerance management, assembly/

performance test: apparatus, measurement standard, data measurement and

analysis)

- Product development requires a lot of research experience, and it is difficult to

introduce a new technology to this long-lasting area of study.

- There are many cases of multi-product small volume production that needs to be

newly developed to meet the requirements of users. The impact of technological

power on related industries is great, and there is a continuous demand for product

development for new fields.

Technical Differentiation

- Technology and process for entire cycle of compressor development except for

manufacturing-cycle analysis, layout design, sizing, 3D CFD, 3D shape formation,

production and assembly, and performance test, etc.-has been secured internally.

- Actions for each technology stage such as performance interpretation and analysis,

optimal shape design, and product performance test are performed.

Excellence of Technology

- Equipped with 20 years of experience in developing high performance compressors

and blowers for various purposes

- Equipped with various S/W for meanline design, 3D geometry formation, and 3D

CFD analysis

Current Intellectual Property Right Status

KNOW-HOW

- Compressor design technology and compressor performance securing/estimation

at design/off-design points

- Various analysis techniques: Multistage performance analysis and unsteady

simulation, shape optimization, RGP (real gas property, refrigerant, supercritical

property) analysis, heat transfer analysis (cooling structure, motor heating),

structural analysis (structure–aerodynamics interaction analysis)

- Detailed drawing and production and assembly: Material, tolerance management,

2D/3D component drawing and assembly drawing

- Performance test: Performance test loop design, performance measurement

complying with international standards

- Rotor design and manufacturing: Rotor-dynamic analysis, shafting design, bearing

and seal selection/design, precision balancing, rotation safety secured

|