Pressure Sensor Using Contact–

resistance Change

Client / Market

- IT industry : Pressure sensor, level sensor, load cell, touch sensor, tactile sensor

- Industrial fields : Automation process, building air conditioning system, firefighting

safety management and environment monitoring system

Necessity of this Technology

- Existing semiconductor type pressure sensor has benefits of outstanding costeffectiveness,

possibility of miniaturization, high-performance and mass production,

but the pressure strength depending on applied pressure is weak and temperature

drift effect is relatively big.

- Also, the signal is weak, which requires separate signal treatment technology and

circuit technology for signal amplification and noise reduction.

Technical Differentiation

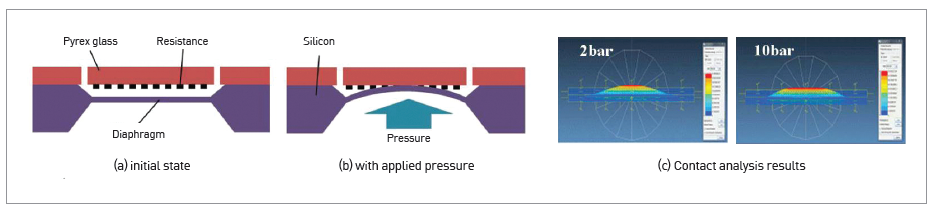

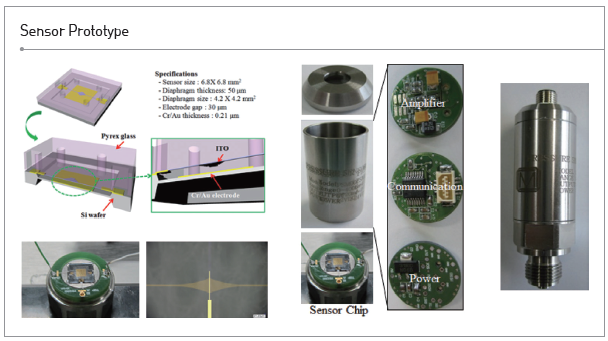

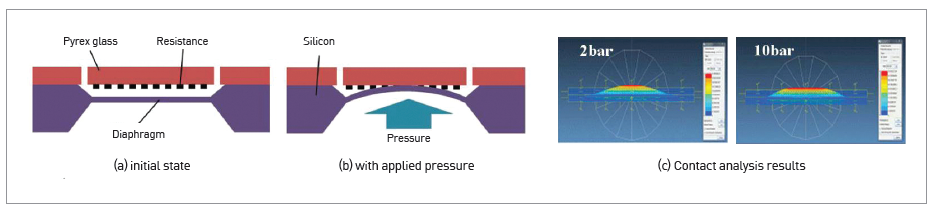

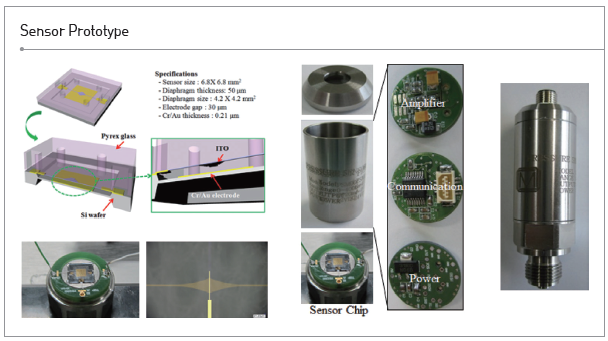

- Proposed pressure sensor is appropriate for pressure detection in stages and

can be realized with the MEMS technology or general machining. By controlling

the pressure switch array’s resistor interval or the curve of the resistor shape, the

measured value by stage can be changed and linearized.

- The working pressure range can be adjusted with the diaphragm design, and

as it does not require an electric signal amplifier and compensation circuit, its

simple structure is superior to existing sensor in terms of technology and price

competitiveness (30% lower than existing sensor)

- Original technology for low-cost, high durability sensor chip to replace existing

semiconductor type pressure sensor (level, limit switch)

Excellence of Technology

- This technology is an original sensor chip technology using pressure/load detection

method without a signal amplification circuit and designed with low-power driving

circuit, which is completely different from existing domestic/international patented

technology.

- Through minimization of electric circuit, durability and reliability are improved

and the manufacturing cost is reduced to secure price competitiveness with the

manufacturing cost 30% lower than for existing technology.

Current Intellectual Property Right Status

PATENT

- Micro Pressure Sensor (KR0773759)

- Linearity-compensated Micro Pressure Sensor (KR0828067)

- High Pressure Switch Using the Contact Resistance Changes (KR1518265)

KNOW-HOW

- Sensor chip linearization design following pressure measurement area

- Sensor durability test assessment technology

- Extra-high voltage limit switch allowing fine adjustment of set pressure error

|