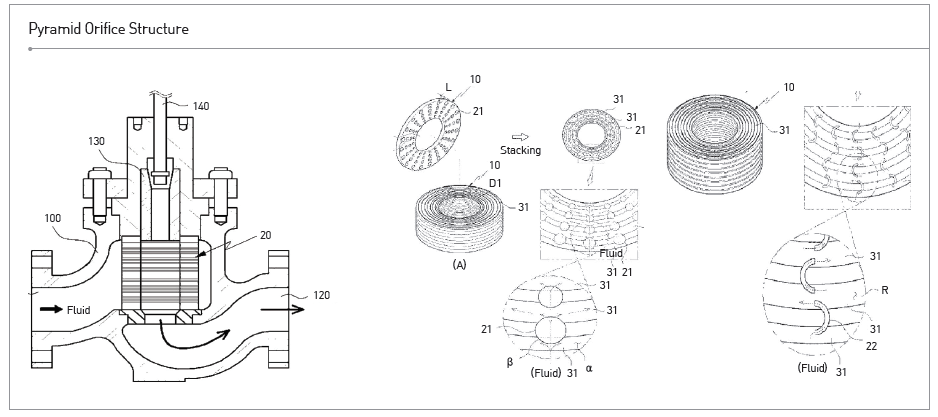

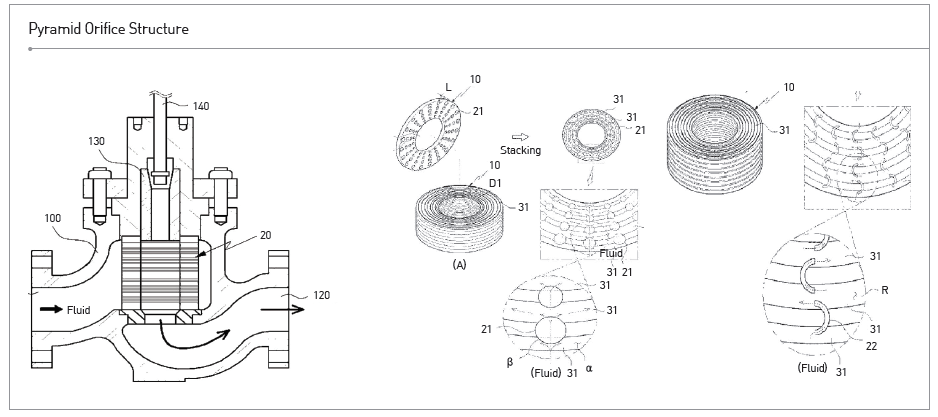

High-differential pressure control valve for offshore plant with a

relatively simple design and easy processing achieving productivity

improvement of differential pressure generator using multi-layer

of discs and the fluid path furrow for creating pressure drop in discs

to weaken cavitation and noise and reduce the pressure of large

amount of fluid

Client / Market

- Shipbuilding/Marine/Nuclear power

Necessity of this Technology

- Demand for pressure reducing technique by creating a longer fluid path within a

designated space mechanically

- Difficulty in high-differential pressure generation drop due to 2D concept design

and machining

- Mechanical high-differential pressure generation is needed for ease application at

offshore plants

Technical Differentiation

- High pressure liquid from deep seafloor can be decompressed relatively easily.

- Valves for deep seafloor are difficult to use with the electrical control method and to

easily generate high pressure drop, but this technology can solve this problem.

- Existing technology is made with the 2D concept design and production, but this

technology is controlled with 3D concept that enables high pressure drop control

and easy adjustment of pressure drop range.

- 3D concept design and production method is flexible depending on the pressure

drop control range adjustment, and there is an economical effect as only one disc

from a set of two discs is used for adjusting the pressure drop control range.

Excellence of Technology

- To generate a greater pressure drop within a given space, the velocity of flow needs

to be accelerated (the speed of liquid going through the valve), and this requires a

design strategy of making a long, narrow fluid path.

- There is a need for measure dealing with cavitation and noise reduction.

- The design is much more favorable than the existing 2D concept fluid path.

- It can be applied to offshore plant, gas and liquefaction line, and coolant control for

nuclear power.

- Excellence of the technology was proven with the Structural Analysis on 2,500 Class

High Pressure Drop Control Valve (KSMTE) and High Pressure Drop Valve Research

Trend (PROCON)

- 25 years of experience in valve research

Current Intellectual Property Right Status

PATENT

- High Pressure Drop Control Valve for Offshore Plant (KR1376093)

- Disc Stacking High Pressure Drop Control Valve for Offshore Plant (KR13561235)

|