Carbon dioxide liquefaction and underground injection apparatus

Client / Market

- CO2 underground injection facility manufacturer, CO2 utilizing industry

Necessity of this Technology

- With ocean storage, CO2 emitted from the earth is expected to be stored for 500

years by releasing CO2 below 3,000 m-deep ocean floor, but due to safety issues

including problems with ecosystems and ocean acidification, this is prohibited by

international laws. Surface storage method takes CO2 to react to addible mineral

such as magnesium or potassium for chemical reaction, but there is an issue of the

cost for chemical reaction and the treatment of resulting chemical products.

- Cooling for CO2 liquefaction requires a great energy consumption, and for

underground injection, it is heated up to a high-pressure supercritical state, which

also requires extensive energy. It is problematic to consume a lot of energy for

liquefaction and storage of CO2, even though CO2 sequestration is required for

environment preservation.

Technical Differentiation

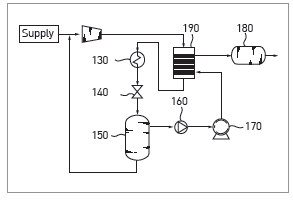

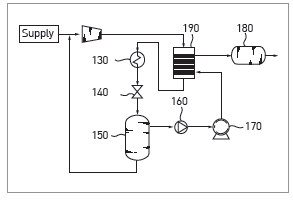

- By resupplying the gas CO2 that went through the gas-liquid separator with a

compressor, energy required for liquefaction is reduced.

- By adopting an injection part with injection pump and heater, CO2 is relatively easily

made into supercritical state for underground injection.

- The injection part includes a high-pressure pump to prevent cavitation.

- By adopting a heat exchanger for heat exchange between CO2 from the injection

pump and CO2 from the compressor, energy consumption for CO2 liquefaction and

storage is significantly reduced.

- The heat exchanger is located between the injection pump and the heater to heat

CO2 with the heat exchanger and then again with the heater to reduce energy

consumption for CO2 storage.

- It is a CO2 liquefaction and underground injection apparatus that saves energy

through heat exchange between CO2 liquefied for transportation and CO2 heated into

the supercritical state for underground injection.

Excellence of Technology

- It is composed of the gas-liquid separator to separate CO2 that went through the feed, compressor, and cooler into gas CO2 and liquid CO2, injection part that converts liquid CO2 into supercritical CO2 for underground injection, and compressor where gas CO2 is resupplied for recompression.

Current Intellectual Property Right Status

PATENT

- CO2 Liquefaction and Underground Injection Apparatus (KR1399442)

KNOW-HOW

- System design and engineering technology

- Flow mixing, heating apparatus design technology

- CO2 heat exchanger design technology

- CO2 injection turbo pump technology

|