Energy saving semiconductor wafer cleaning single wafer type

megasonic that requires only 1/30 of power consumption and 1/10

cleaning fluid of existing batch type

Client / Market

- Wafer cleaning, NEMS cleaning field, electronic component-HDD, etc.-cleaning field

Necessity of this Technology

- Cleaning process is a major process that accounts for 30 to 40% of the entire

semiconductor manufacturing process, a key industry in Korea, and an important

process that determines the throughput, but the technology localization rate of

cleaning device (spin type) is only 37.3%

- Megasonic is divided into the batch type that cleans multiple wafers at once and single wafer type that cleans one wafer at a time. Cleaning efficiency enhancement

and cleaning time shortening are important for megasonic cleaning.

- Existing batch type megasonic technology over consumes electricity and cleaning fluid, and cleaning efficiency is declined due to low uniformity of sound pressure distribution, and the pattern damage occurs from the peak sound pressure.

Technical Differentiation

- Semiconductor production expansion effect from yield improvement (1.526 trillion won/year)

- Semiconductor manufacturing cost reduction effect from yield improvement (915.6 billion won/year)

- Semiconductor manufacturing energy reduction effect from yield improvement and physical technology (62.7 billion won/year)

- Related cost reduction effect from using physical cleaning technology (59.5 billion won/year)

- Work environment improvement effect from using physical cleaning technology

- Superfine cleaning technology applying highly uniform sound pressure distribution of ultrasonic for improved cleaning efficiency

Excellence of Technology

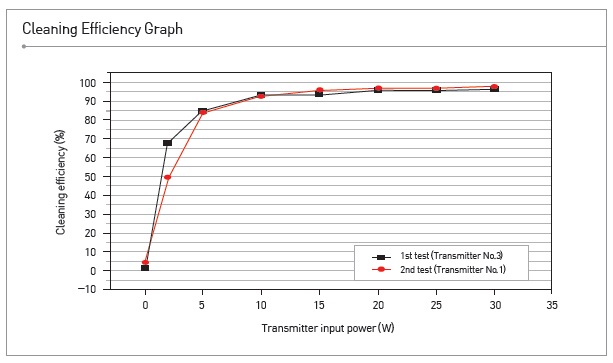

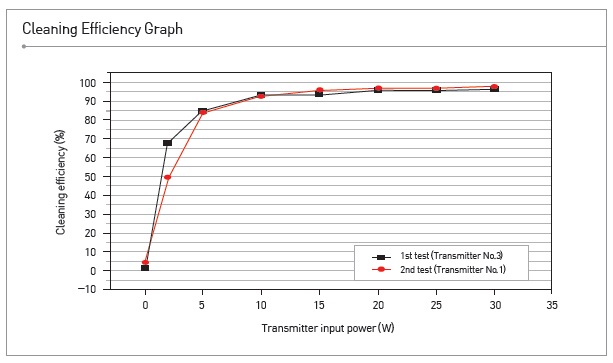

- Single wafer type 1 MHz megasonic transmitter performance test result is as follows:

- Average sound pressure to maximum sound pressure 295%, standard deviation of

37%, cleaning efficiency of 96.5%

- Resonant frequency generation error of ±0.9%; resonance design for transmitter

using FEM and sound field analysis technology secured

- DSS type oscillator that can fix frequency

- Adopting fine output control circuit of 0.1W interval

- Driving frequency fluctuation range error of ±1.3 kHz

Current Intellectual Property Right Status

PATENT

- Large Area Ultrasonic Cleaning Apparatus (KR1827296)

- Large Area Ultrasonic Fine Cleaning Apparatus (KR1599214)

- Ultrasonic Cleaning Apparatus (KR1002706)

- Ultrasonic Fine Cleaning Apparatus (KR1002706 JP5517227 US13)

- 520838 CN201080061173.4

- Ultrasonic Cleaning Apparatus and Cleaning System Using Apparatus (KR1347068)

- Cleaning Apparatus Using Ultrasonic Wave (KR852396)

- Ultrasonic Fine Cleaning Apparatus (KR979568)

- Ultrasonic Cleaning Method and Apparatus (KR523934)

- Cleaning Ultrasonic Wave Apparatus and Ultrasonic Cleaning System (KR702596)

- Cleaning Ultrasonic Wave Apparatus and Ultrasonic Cleaning System (KR827618)

- Ultrasonic Cleaning Apparatus (KR784903)

- Ultrasonic Cleaning System Using Cleaning Ultrasonic Wave Apparatus (KR817872)

- Ultrasonic Cleaning System Using Cleaning Ultrasonic Wave Apparatus (KR748480)

- Single Wafer Type Ultrasonic Cleaning Apparatus Using Multi-Frequency (KR951922)

KNOW-HOW

- Precision design for ultrasonic transmitter using FEM analysis

- Fine cleaning technology using ultrasonic wave.

|