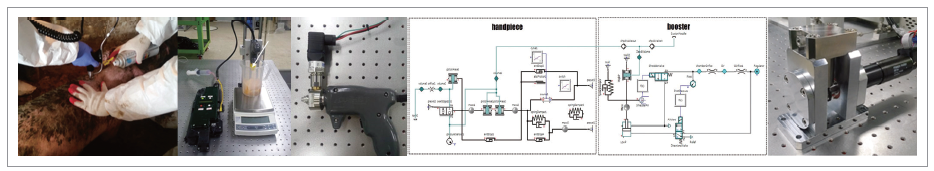

The needle-free injector design technology allows instant

intradermal or intramuscular injection of accurate volumes without

using needle through pressurization of drug in order to solve various

problems caused by existing injection methods using a needle

syringe.

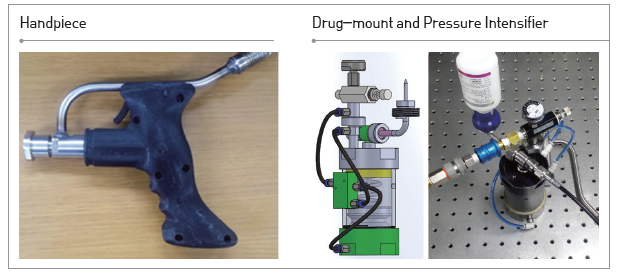

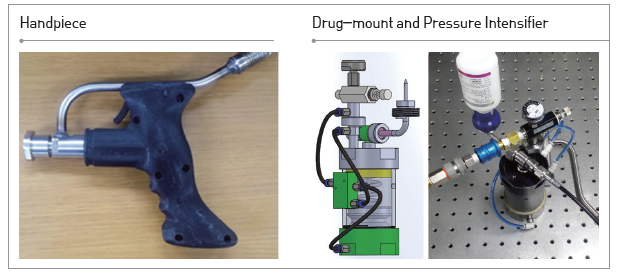

Portable type needle free injector is developed so that a single operator

working in the field can vaccinate a large scale livestock farm.

Client / Market

- Large scale livestock farms, public quarantine institutes, injecting drug (foot and mouth disease vaccine, etc.) manufacturers, and pet hospitals.

Necessity of this Technology

- Vaccines or drugs to livestock are usually delivered with a needle-syringe so there is a possibility of disease spread due to reuse of needles.

- Injection of accurate amount on the right spot is difficult using a syringe with a needle due to animal movement, and there are issues regarding increasing fatigue of the worker and possibility of safety accident.

- Pork quality may decline due to the needle mark and broken needle during injection and stress caused from injection.

- Imported needle-free injectors are expensive, heavy, or make noise during operation that is why their use is limited at livestock farms.

Technical Differentiation

- The use of compressed gas to amplify the pressure of drug makes less noise and does not require electric battery.

- The hand-piece is light-weight and causes less fatigue when using long hours, and the triple safety device keeps the worker safe.

Excellence of Technology

- Prevention of accidents and injuries which might occur with the existing needle syringe vaccination and reduction in vaccination time

- Reduced animal stress and prevention from needle stick injuries

- Adjustment of drug injection pressure and volume to inject fixed dose to required depth

- Reduction in costs occurring from drug loss and purchasing expensive imported products

Current Intellectual Property Right Status

PATENT

- Needle-free Syringe (high pressure pump valve type) (KR1313632)

- Needle-free Syringe (elastic body impact type) (KR1313633)

- Pressure-controlled Needle-free Injector for Injection Volume Adjustment (KR2016 - 0163067)

KNOW-HOW

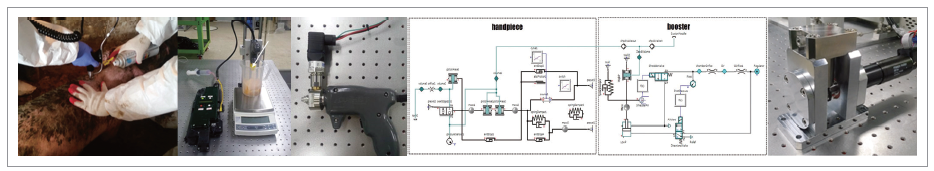

- Axiomatic design technology for design parameter selection to achieve target injection volumeand pressure

- Modeling and dynamic simulation technology using design blueprint before production

- Needle-free injector performance assessment technology

- Small high-pressure plunger pump and piezoelectric-driven highspeed valve design technology

- Apparatus design for variable injection volume control technology

|