Advanced high-efficiency non-leveling accelerated cooling

technology for thick plate to improve energy efficiency in the thick

plate processing

Client / Market

- Major steel manufacturers/cooling facility manufacturing market

Necessity of this Technology

- There is a need for uniform cooling and residual water removal.

- Existing accelerated cooling control technology for thick plate or steel plate could not cool the plate uniformly that the plate deformation occurred, and most of the times, leveling process consumed a lot of energy and lowered the productivity.

- When accelerated cooling control was not done properly in the thick plate or steel plate manufacturing process, large deformations occurred from thermal stress caused by non-uniform cooling.

- Therefore, a uniform cooling method is needed to minimize plate deformation.

Technical Differentiation

- It is an innovative steel cooling process technology that uses accelerated cooling technology that could significantly reduce thick plate deformation and unnecessary energy consumption put into leveling in the post treatment. It can achieve revolutionary energy efficiency improvement.

- By eliminating the leveling process in the post treatment, the thick plate or steel plate production time can be shortened, that the productivity can be enhanced.

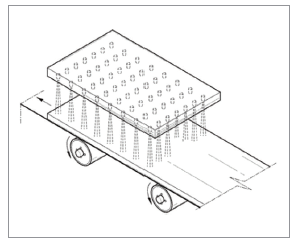

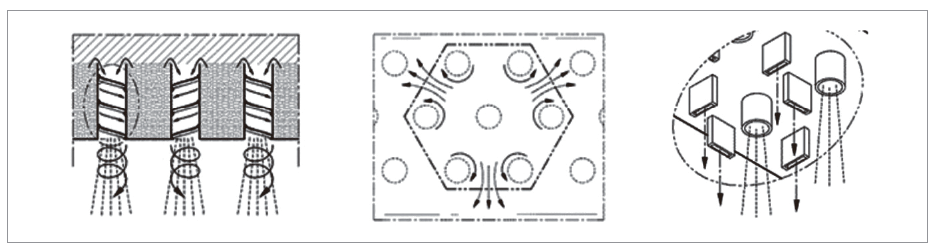

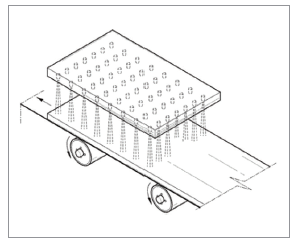

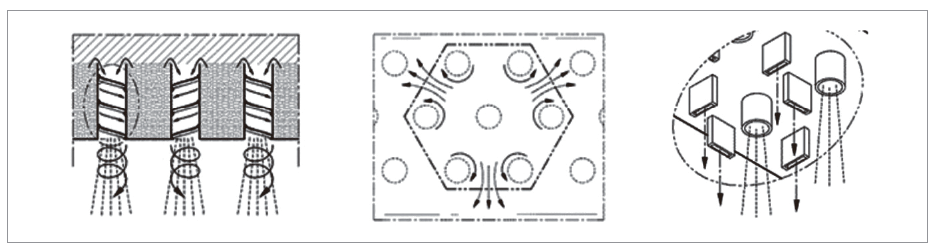

- The cooling apparatus has distinctive technology using multiple circular jet nozzles with swirl generator to cover unevenly cooled area between the nozzles and effectively discharging residual water by adjusting the swirl direction.

Excellence of Technology

- Multiple circular jet nozzle is one of the main cooling apparatus with high cooling ability and is widely used for thick plate cooling control.

- However, its drawback is uneven cooling between the nozzles, and to overcome such shortcomings, following cooling apparatus is proposed.

- Using circular jet nozzles with swirl generator, areas with uneven cooling between the nozzles

are covered, and the residual water is discharged effectively by adjusting the swirl direction.

- It is a cooling apparatus using a dual-pipe multiple jet nozzle to increase the intensity of

turbulence and improve the cooling ability while effectively discharging residual water.

- 2 principal researchers and 4 senior researchers are participating in the research for technology development.

Current Intellectual Property Right Status

PATENT

- Cooling Ability Measuring Apparatus (KR1168385)

- Cooling System for Thick Plate or Steel Plate (KR1190609)

- Multiple Injection Type Cooling System for Thick Plate or Steel Plate (KR1167621)

- Cooling Ability Measuring Apparatus (JP147110/2012)

- Swirling Nozzle (KR1442647))

KNOW-HOW

- Multiple nozzle design technology applying swirl generator

- Swirl generating nozzle performance assessment technology

|