An optimal oil mist collection apparatus that combines unipolar charging, centrifugal and electrostatic dust collection technique

Client / Market

- Machining industry using processes like cutting, grinding, and cleaning, food disposal facility, odor control market

Necessity of this Technology

- Oil mist is very fine; therefore, it is difficult to check if it has occurred. It is spread in the air, and the machine operator inhales the oil mist.

- Inhaling oil mist reduces the work efficiency, and if serious, it sticks to the body of the operator or the machine or products. Due to this issue, an oil mist collector is installed at the work area.

- A collection apparatus using fiber filter filters the air polluted with oil mist through the fiber filter to separate oil mist from the air.

- A collector using a fabric filter is easy to install and inexpensive, but the filter needs to be replaced periodically, and due to frequent filter blocking, it is difficult to maintain a constant amount of air going through the filter. Also, the filter is treated as industrial waste, and its treatment is also an issue.

Technical Differentiation

- The oil mist does not stick to the collecting plate surface, and separate cleaning process is unnecessary.

- A fine-size oil mist can be condensed in the charger.

- With the fine oil mist treatment through electrical charging, efficiency is enhanced and pressure loss is very low.

- Electrically charged oil mists are piled up on the collection plate surface, and piled oil mists are condensed on the collection plate surface and fall once it gains weight. Since oil mists do not stick on the plate, cleaning is unnecessary.

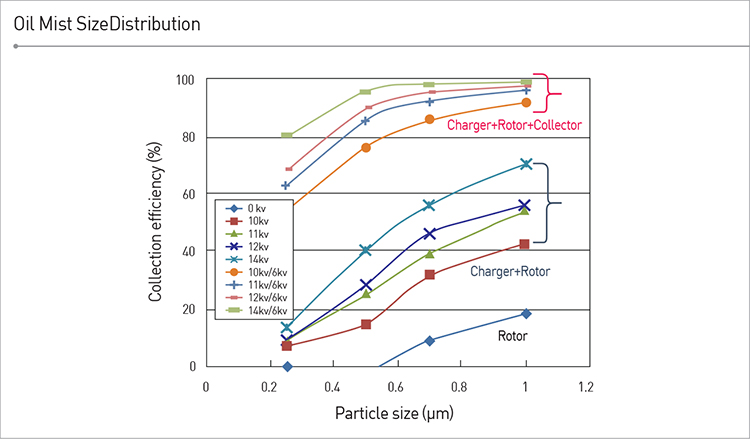

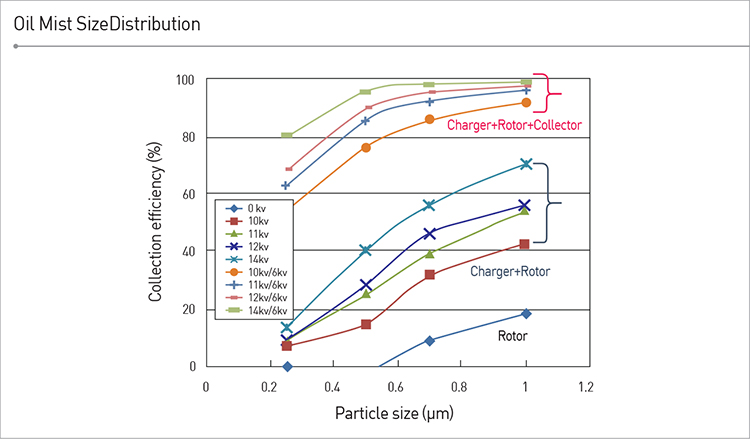

- By electrically charging the oil mists primarily and treated through the rotor blades, and an electric field is generated in a small space to electrically charge the oil mists that were not treated through the rotor blades to improve the oil mist removal efficiency.

Excellence of Technology

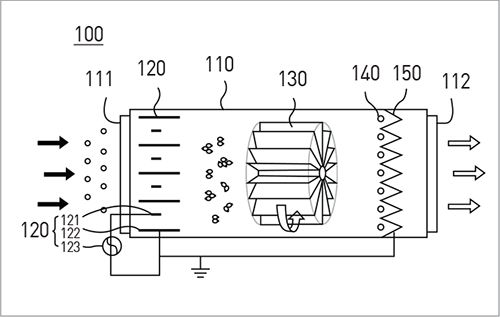

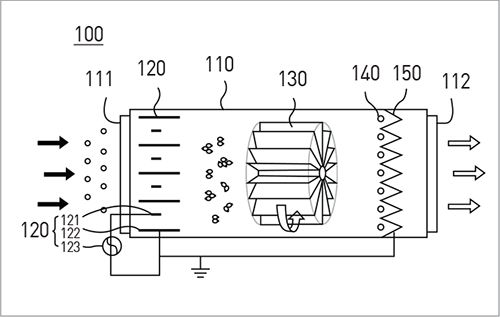

- Entrance: Oil mist-polluted gas or liquid enters

- High voltage generator: High voltage is generated

- Charger: Supplied with the high voltage from the high voltage generator, unipolar charging is applied to oil mists in the polluted air entered through the entrance. Some oil mists are collected.

- Rotor: The air including oil mist that came through the charger comes in. With forced rotation of the air, oil mists separated from the air due to inertial impact are collected, and uncollected fine oil mists and unipolar ions are combined to enhance the fine mist electrical charging efficiency.

- Collector: Electrically charged fine oil mist that were not collected in the charger and the rotor are separated with the electrostatic force.

- Exhaust: Air separated from oil mist is discharged outside

Current Intellectual Property Right Status

PATENT

- Apparatus for Collecting Oil Mist (KR0344758)

- Apparatus for Collecting Oil Mist Using Unipolar Charging, Centrifugal Method (KR1157822)

- Apparatus for Collecting Oil Mist (KR2013-0031869)

- Apparatus for Treatment of Oil Mist (KR1486887)

- Apparatus for Collecting Oil Mist (KR1471976)

|